Laves phase eutectic alloy with high strength, high hardness and high thermal stability and preparation method of laves phase eutectic alloy

A high thermal stability, eutectic alloy technology, applied in the field of mechanical processing, can solve the problems of difficult to prepare large-sized and special-shaped products, strict sintering temperature requirements, poor thermal stability, etc., to achieve low material cost, simple manufacturing process, high thermal stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

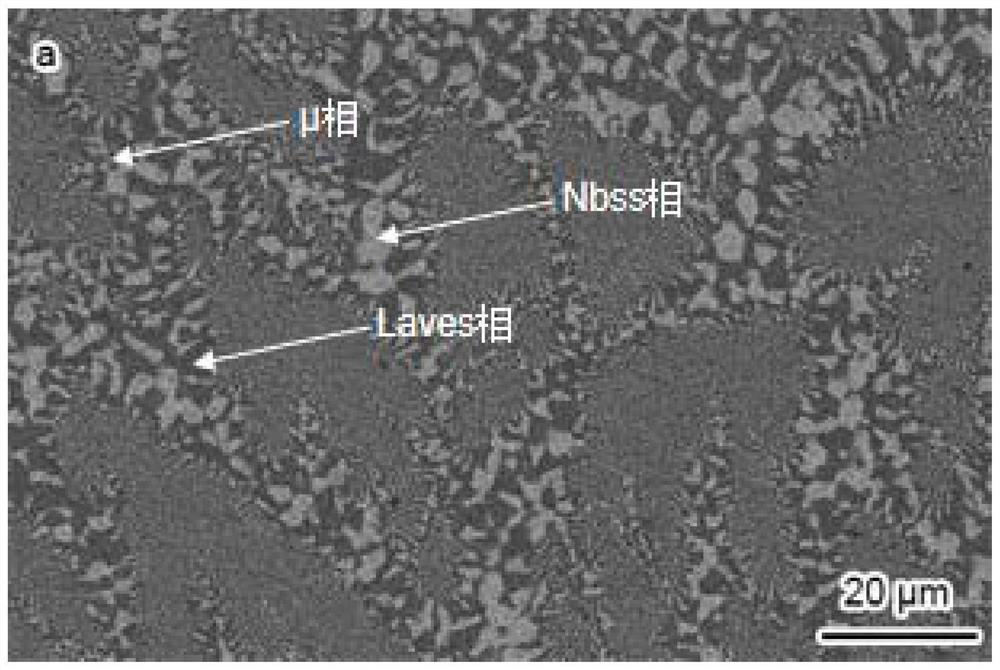

[0025] The content of the present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

[0026] A Laves phase eutectic alloy with high strength, high hardness and high thermal stability and a preparation method thereof, is characterized in that it comprises the following steps:

[0027] The polished and cleaned high-purity metal is weighed according to the chemical composition Cr-22.93Fe-53.68Nb (at.%);

[0028] The raw materials are niobium blocks with a purity of 99.95%, chromium flakes with a purity of 99.95%, and iron flakes with a purity of 99.95%;

[0029] Put the raw materials into the water-cooled copper crucible of the non-consumable arc melting furnace in order of melting point from low to high, that is, put them in the order of iron, chromium and niobium, and put them in another crucible to remove For the metal Ti with residual oxygen in the furnace, the vacuum degree in the furnace is evacuated to 3×10 -3 ~6×10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com