Efficient biological denitrification process for coking wastewater

A technology for biological denitrification and coking wastewater, which is applied in water pollutants, biological treatment devices, biological water/sewage treatment, etc. To achieve the effect of saving carbon source and aeration energy consumption, good degree of automation, and improving the biochemical properties of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The wastewater enters the fully mixed hydrolysis tank after degreasing pretreatment and the homogenization of the adjustment tank. The sludge concentration in the reaction tank is controlled at 5-10g / L, the DO in the wastewater is lower than 0.5mg / L, and the pH is maintained at 6-8.5 During the period, the HRT is controlled at about 10 hours, and phosphorus is added quantitatively. The mud-water mixing is controlled by mechanical stirring, and the mud-water separation is realized in the hydrolysis sedimentation tank. The sludge returns to the front-end hydrolysis tank, and the sludge return flow is determined according to the sludge concentration in the reactor. and residual sludge discharge concentration.

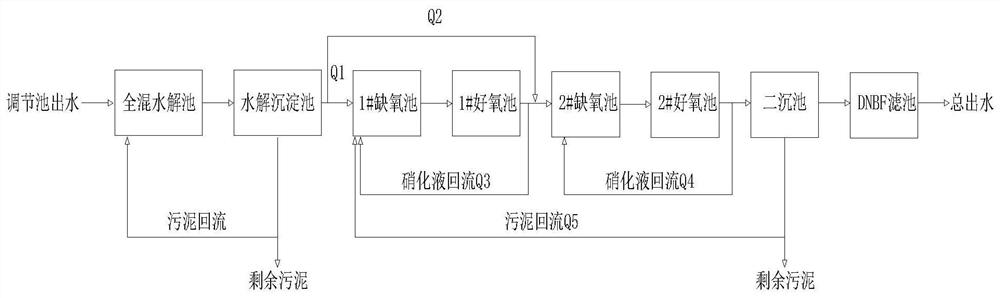

[0038] The supernatant Q1 of the hydrolysis sedimentation tank is set at 0.6Q to self-flow to the 1# anoxic tank, mixed with the 0.5Q return flow nitrification liquid of the 1# aerobic tank, and the secondary settling return sludge Q, and the denitrification reaction...

Embodiment 2

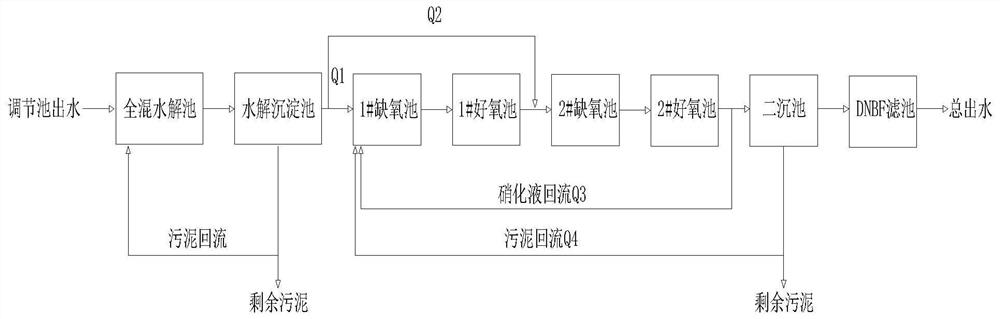

[0046] Example 2 and Example 1 adopt the same hydrolysis pretreatment and hydraulic distribution, the biggest difference is that the nitrification liquid backflow adopts the cross backflow method, and the total backflow is 2Q.

[0047] Ammonia distillation wastewater enters the fully mixed hydrolysis tank after degreasing pretreatment and adjusting tank homogeneity and equalization. The sludge concentration in the reaction tank is controlled at 5-10g / L, the DO in the wastewater is lower than 0.5mg / L, and the pH is maintained at 6- Between 8.5, HRT is controlled at about 10h, and phosphorus is added quantitatively. The mud-water mixing is controlled by mechanical stirring, and the mud-water separation is realized in the hydrolysis sedimentation tank. The sludge is returned to the front-end hydrolysis tank, and the sludge is determined according to the sludge concentration in the reactor. Return flow rate and residual sludge discharge concentration.

[0048] The supernatant Q1 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com