A Spiral Plate Membrane Reactor for Hydrogen Production with Atomized Feed of Liquid Fuel

A technology of liquid fuel and membrane reactor, applied in the field of hydrogen energy, can solve the problems of long gasification process of liquid fuel, insufficient heat exchange, unfavorable compact structure, etc., to improve heat transfer efficiency and thermal energy utilization rate, and to achieve a reasonable and compact structure , the effect of easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

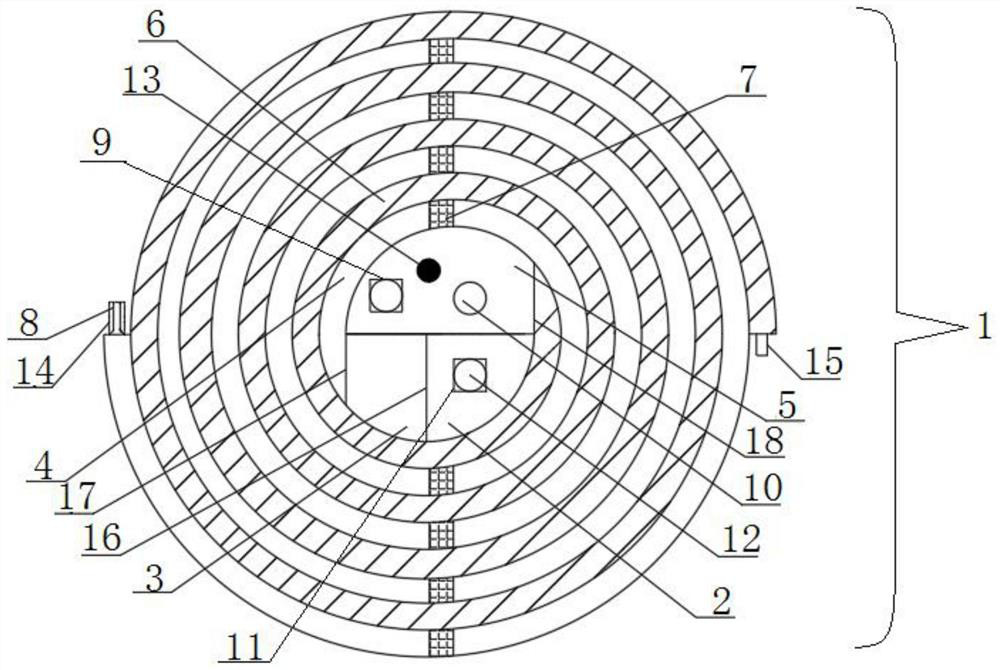

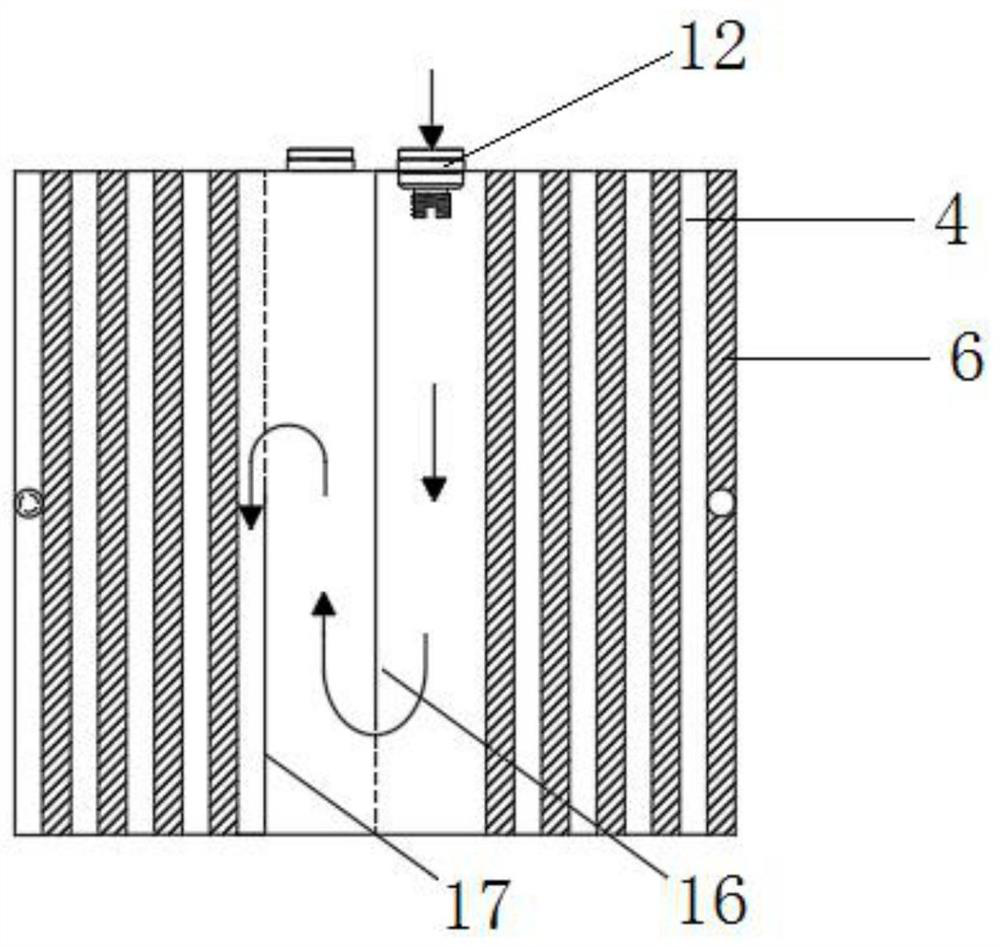

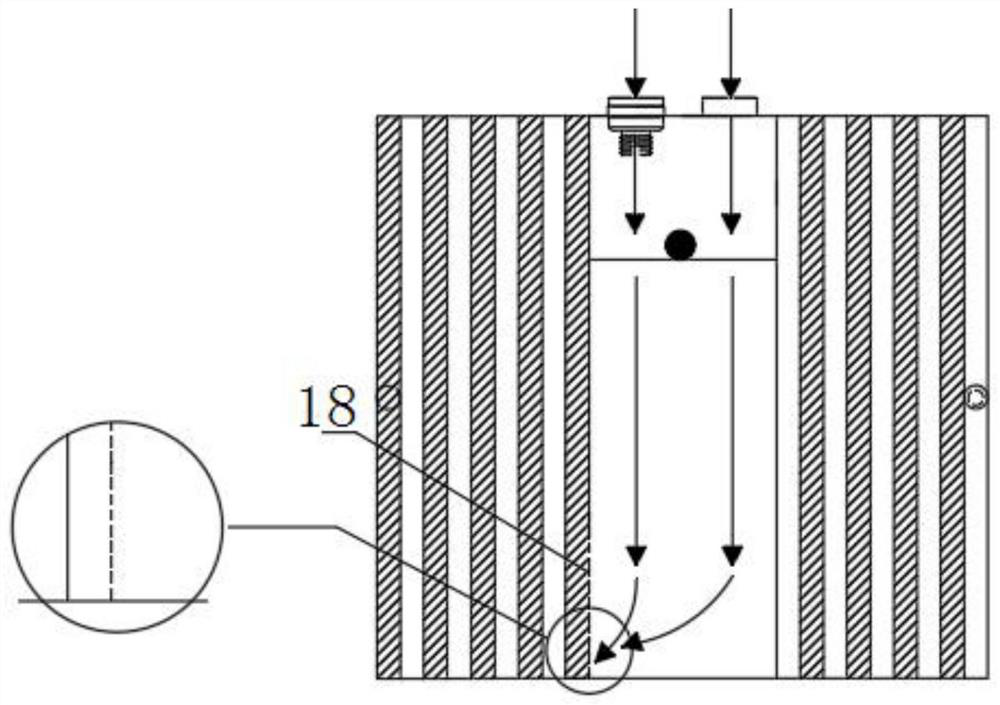

[0035] Such as figure 1As shown, this embodiment provides a hydrogen production spiral plate membrane reactor 1 for liquid fuel atomized feed, including a preheating chamber 2 located in the central part, a gasification buffer chamber 3 and an ignition chamber 5, and a central Part of the peripheral combustion chamber 6 and reforming chamber 4, and the reforming chamber 4 and the combustion chamber 6 are alternately covered in a double helix form to form a double helix structure cavity; the preheating chamber 2 passes through the gasification buffer chamber 3 and the reforming chamber 4 The inlet of the inlet is connected, that is, the preheating chamber 2, the gasification buffer chamber 3 and the reforming chamber 4 are connected to each other, and the preheating chamber 2 and the gasification buffer chamber 3, and the reforming chamber 4 and the gasification buffer chamber 3 Partial barriers are carried out between them by partitions; the preheating chamber 2, the gasificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com