Essence capsule and preparation method thereof and wash supplies

A technology of essence capsule and essence, applied in the field of daily chemical cleaning and care, can solve the problems of poor encapsulation effect, unsatisfactory fragrance retention effect, large size and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] Specifically, the preparation method of the essence capsule of an embodiment comprises the following steps:

[0046] Step S110: mixing the essence and isocyanate to form an oil phase.

[0047] Among them, the isocyanate is diisocyanate or polyisocyanate. In one embodiment, the isocyanate is selected from at least one of toluene diisocyanate, xylene diisocyanate, 4,4'-diphenylmethane diisocyanate and isophorone diisocyanate. It can be understood that the isocyanate is not limited to the above-mentioned substances, and can also be other isocyanates produced in the field, such as hexamethylene diisocyanate, hexamethylene diisocyanate and the like.

[0048] Specifically, the incense is selected from at least one of floral essential oils, fruity essential oils, woody essential oils and powdery essential oils. For example, the floral essential oil can be lavender essential oil. It can be understood that the essence is not limited to the types listed above, and it can also ...

Embodiment 1

[0091] The preparation process of the essence capsule of the present embodiment is specifically as follows:

[0092] (1) Mix 2.55g (0.011mol) of isophorone diisocyanate and 7.9mL of lavender essential oil to form an oil phase and set aside.

[0093] (2) Put the oil phase in step (1) into 100 mL of 1% polyvinyl alcohol aqueous solution by mass percentage, and homogenize at 9600 rpm for 5 min to form an emulsion.

[0094] (3) Add 100mL of 0.15% sodium alginate aqueous solution, 3.84g (0.0096mol) PEG400 and 0.22g catalyst dibutyltin dilaurate to the emulsion in sequence, and stir at room temperature for 50min to obtain the essence capsule prepolymer .

[0095](4) Add 0.11 g (0.95 mmol) of chain extender 1,6-hexamethylenediamine to the fragrance capsule prepolymer at a temperature of 70° C., react for 1 hour and then centrifuge to obtain lavender fragrance capsules.

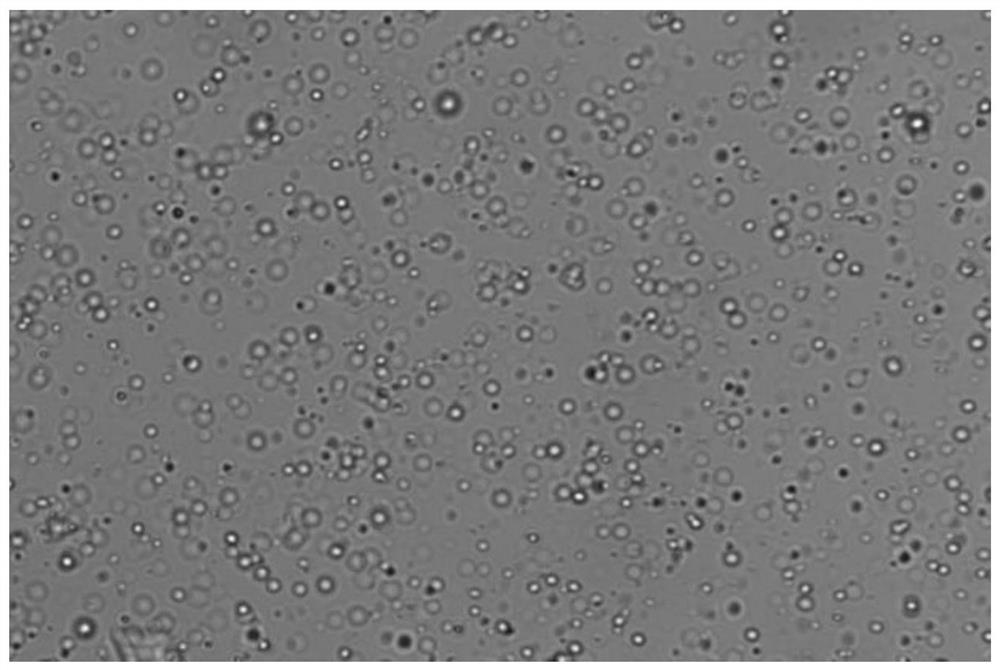

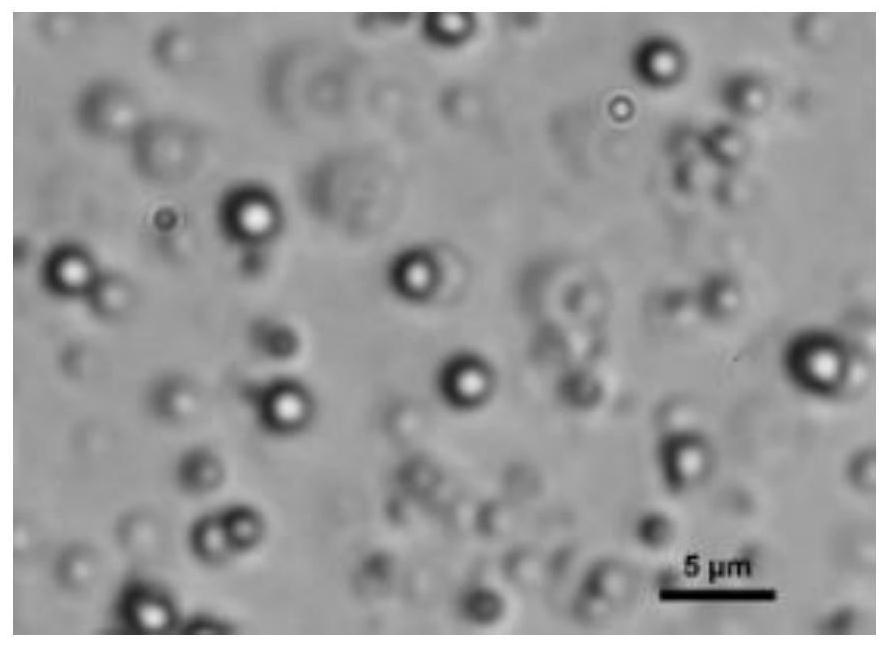

[0096] Adopt optical microscope to observe the essence capsule prepared by the present embodiment, obtain as fol...

Embodiment 2

[0102] The preparation process of the essence capsule of the present embodiment is specifically as follows:

[0103] (1) Mix 2.55g of isophorone diisocyanate and 8.1mL of fresh floral essential oil evenly to form an oil phase and set aside.

[0104] (2) Put the oil phase in step (1) into 100 mL of a 1% polyvinyl alcohol aqueous solution by mass percent, and homogenize at a speed of 9600 rpm for 5 min to form an emulsion.

[0105] (3) Add 100 mL of 0.15% aqueous sodium alginate solution, 3.84 g of PEG400 and 0.22 g of catalyst dibutyltin dilaurate to the emulsion in sequence, and stir at room temperature for 50 min to obtain the essence capsule prepolymer.

[0106] (3) Add 0.11 g of chain extender catechol (0.001 mol) to the fragrance capsule prepolymer at a temperature of 70° C., react for 1 hour and then centrifuge to obtain fresh floral fragrance capsules.

[0107] Adopt optical microscope to observe the essence capsule prepared by the present embodiment, obtain as follows ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com