High-salt preserved szechuan pickle wastewater treatment system

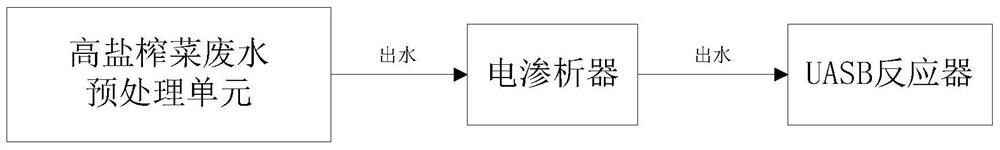

A mustard waste water and treatment system technology, which is applied in food industry waste water treatment, water/sewage treatment, water treatment parameter control and other directions, can solve problems such as the failure of the electrodialyser to work normally, the salinity reduction of high-salt mustard waste water, etc., to reduce pollution Concentration, reduction of salt loss, effect of shortened process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Adopt the present invention to process the mustard mustard wastewater of a mustard mustard factory in Fuling, Chongqing according to the above steps, and the COD and NH in the mustard mustard wastewater 4 + -N and SS water quality are 14380~14410, 441~453 and 218~230mg / L respectively, and the salinity is 7%;

[0040]Through the grille, go to the adjustment pool to adjust the pH of the solution to 6.5-8.5, enter the circulation reaction tank for bioaugmentation treatment, and activate the halophilic bacteria agent (inoculum size is 5% to 10%) (the frozen halophilic composite bacteria seeds liquid to expand culture, add medium to make it grow to the optimal concentration) 3d, set HRT=12h sequential batch type intermittent water change, drainage ratio is 1 / 3, aeration intensity is 1000L / h, sludge concentration is 3200mb / L; after coagulation, flocculation, and sedimentation treatment, the coagulation and flocculation residence time is set to 0.7h, the dosage of coagulant ...

Embodiment 2

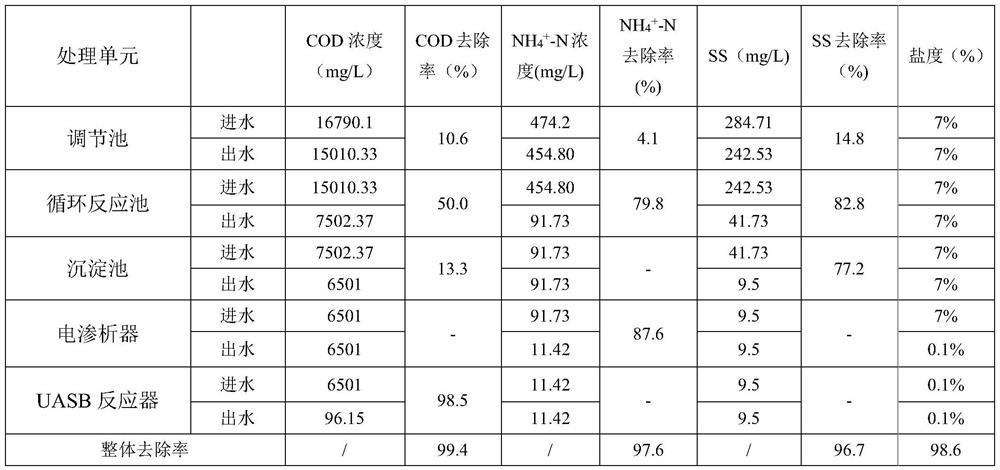

[0046] According to the above steps, the present invention is used to treat the comprehensive wastewater and mustard pickling wastewater mixed liquid produced in the production process of a pickled mustard factory in Banan District, Chongqing City, and the mixed solution is sequentially passed through the high-salt mustard mustard wastewater pretreatment device, electrodialyzer, UASB After the reactor, the final effluent can meet the discharge standard, and the specific treatment conditions are shown in Table 2.

[0047] Table 2

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com