Waste fluid treatment apparatus and processing water regeneration system

A technology for waste liquid treatment and processing waste liquid, which can be used in sedimentation treatment, water/sewage treatment, natural water treatment, etc. It can solve the problem of time-consuming, and achieve the effect of reducing burden, improving sedimentation speed and accelerating sedimentation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

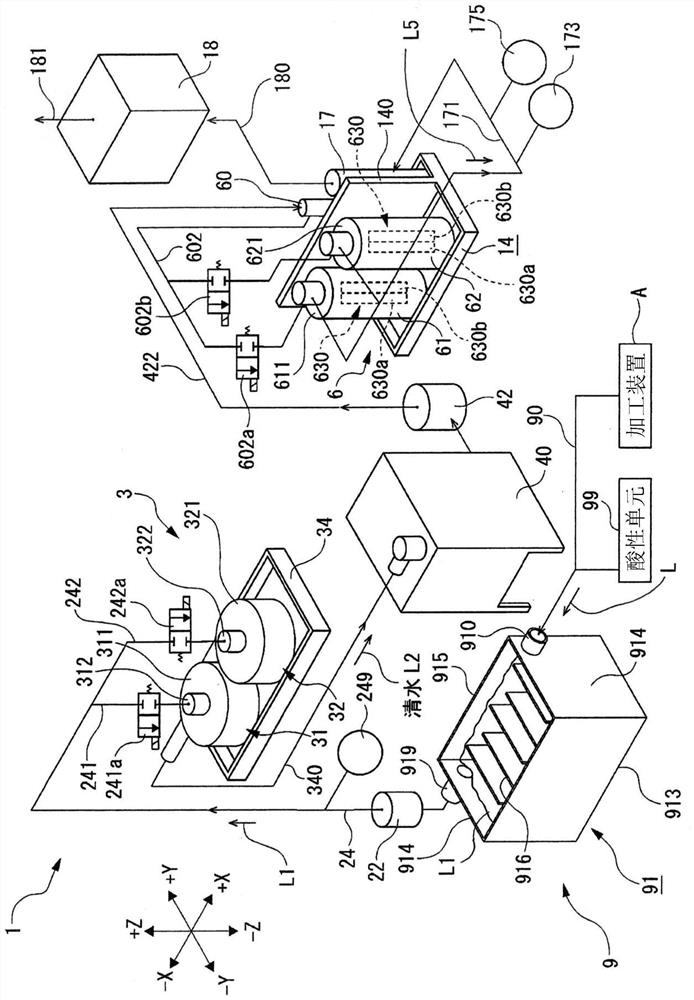

[0028] figure 1 The machining device A is shown is a processed product (e.g., silicon wafer, silicon ingot) that is maintained at the chuck table, while the machining device A is supplied to the machining water (e.g., pure water) while using a rotating grinding abrasive. Wait, etc., the grinding device is made, or the rotating cutting tool is applied to the processed product (e.g., silicon wafer, etc.) held in the chuck table, while supplying the processed water. Cut cutting devices, and the like.

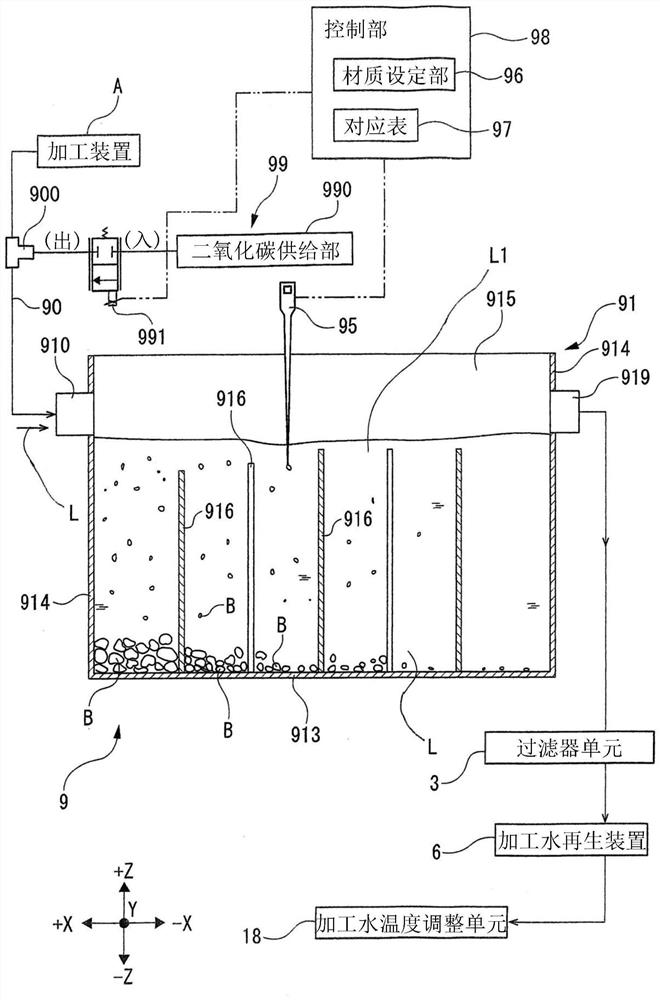

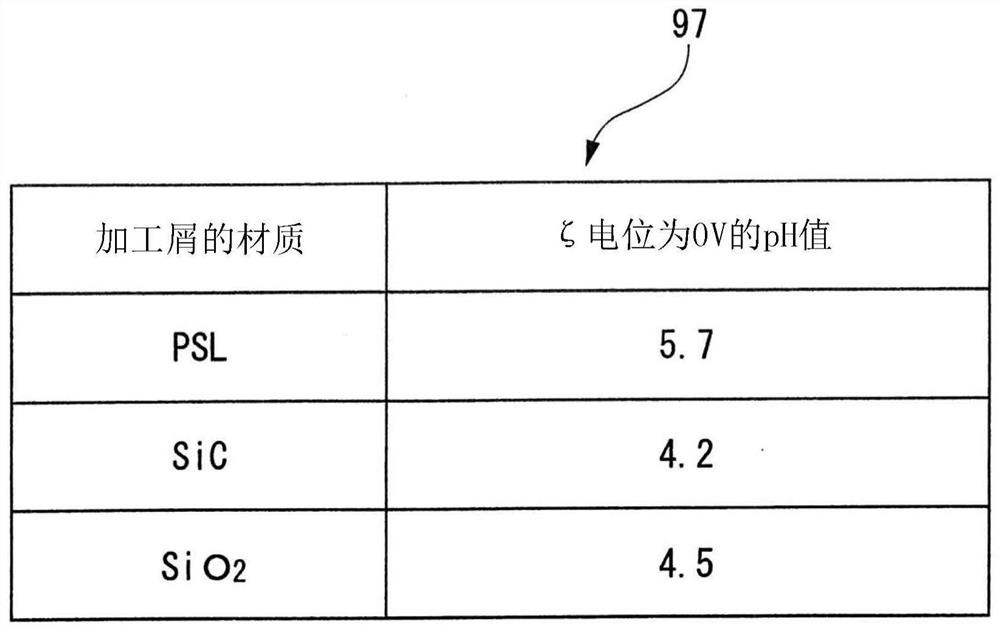

[0029] The waste liquid treatment apparatus 9 of the present embodiment is attached to the processing waste liquid flow into the tube 90 composed of a metal pipe or a tube or the like having a flexible tube, and the waste liquid treatment device 9 receives the discharge from the processing device A. Contains pattern B (eg, SiO) 2 Dia, PSL (polystyrene emulsion) crumping or SiCzuce, refer to figure 2 The processing waste liquid L is precipitated from the processing waste B to remove th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com