Self-locking crucible for diffusion couple in-situ detection and preparation method and application thereof

An in-situ detection and diffusion couple technology, applied in crucibles, measuring devices, fluorescence/phosphorescence, etc., can solve problems such as reducing detection accuracy, increasing the difficulty of sample preparation and processing of diffusion couples, and inability to obtain information on the initial kinetic state of compounds. , to avoid sample contamination, improve experimental efficiency and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

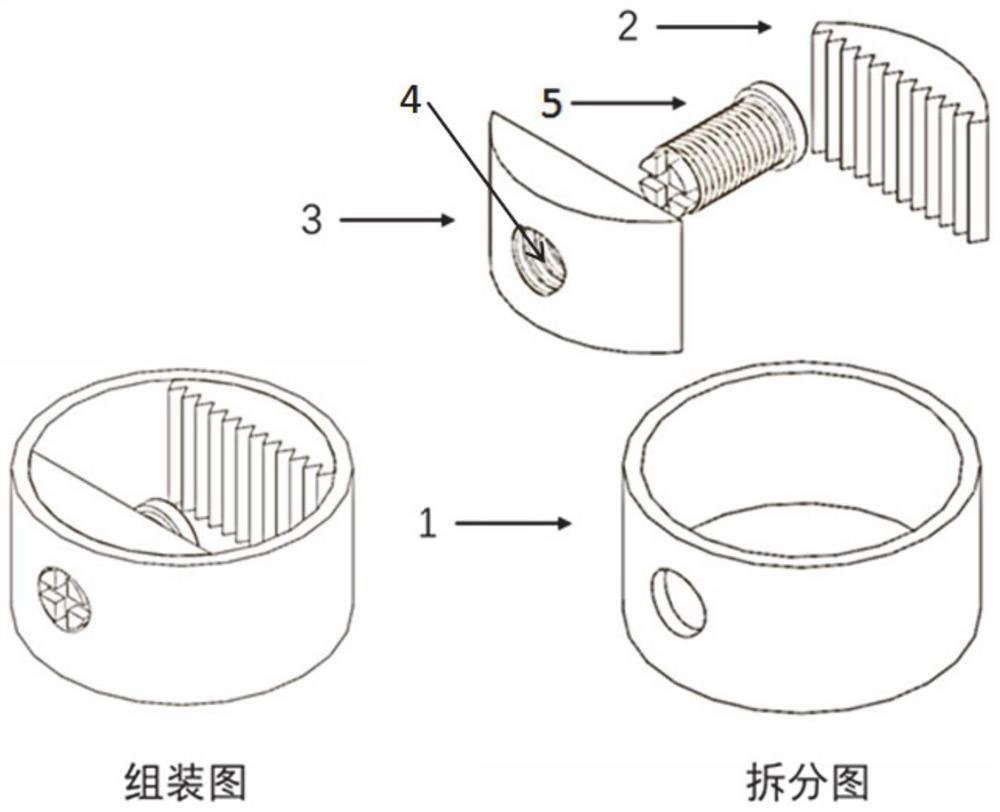

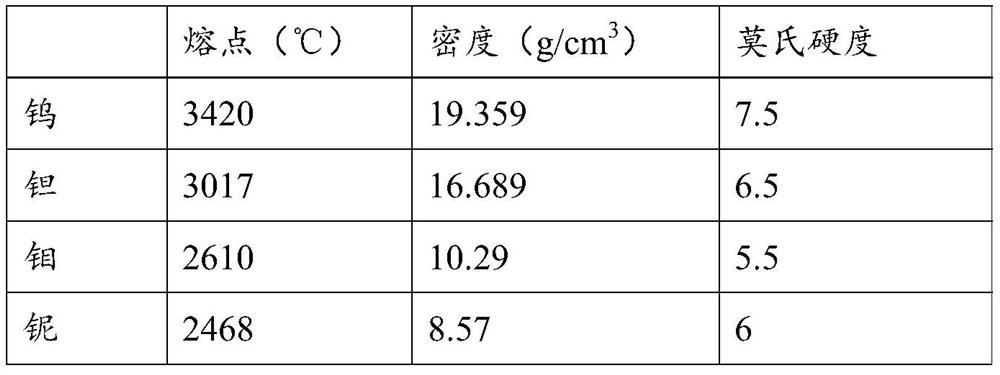

[0041] In the preparation of the self-locking crucible for in-situ detection of the diffusion couple, the size is small and the wall thickness accuracy is high, and the raw material is a refractory hard metal, so it is difficult to use traditional machining (stamping) to prepare. The powder metallurgy method can prepare materials such as refractory metals; the powder metallurgy process does not melt the material during the material production process, and will not mix impurities brought by other substances, and the sintering is carried out in a vacuum and reducing atmosphere. It will not be oxidized and will not have any contaminating materials, so the purity of the product is relatively high. The powder metallurgy method can ensure the correctness and uniformity of the material composition in the ratio; the loss of metal produced by this method is only 1-5%, while the general processing will consume 80% of the metal. The method of powder metallurgy can produce high-purity mat...

Embodiment 1

[0056] In the Mg-Al-Zn alloy system, the method for detecting the φ phase diffusion behavior of the ternary intermetallic compound comprises the following steps:

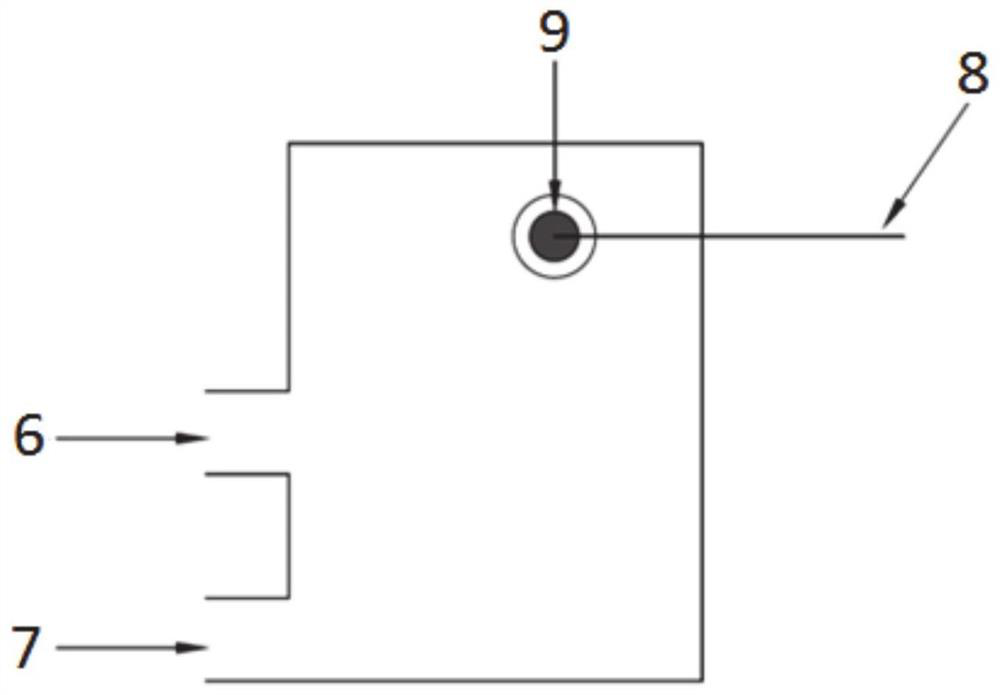

[0057] 1. Design and preparation of the crucible: design the crucible as figure 1 As shown, the diameter of the crucible is 10 mm, and the height is 4 mm. There is no need to consider the cutting shape of the Mg-Al-Zn alloy, but a sufficiently flat diffusion contact surface must be reserved. Considering that the measured temperature of the Mg-Al-Zn alloy is 360°C, and the tantalum fixture does not react with the Mg-Al-Zn alloy, tantalum with a purity of 99.99% is selected as a raw material. The shape of the tantalum powder in the raw material is irregular, and the particle size is 1000-6000 mesh. The pure tantalum was ball milled and mixed for 6 hours, the ball milled tantalum powder was sieved and dried, then compressed and sintered at 3500°C, heat treated for 5 hours, quenched in hot oil and tempered at 200°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com