Assembled form-removal-free steel bar truss floor support plate

A steel truss, formwork-free technology, applied in the direction of floors, structural elements, building components, etc., can solve the problems of building span limitation, span increase, and maximum span small, so as to shorten the construction period and construction cost, and achieve the degree of prefabrication High, the effect of increasing the contact length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

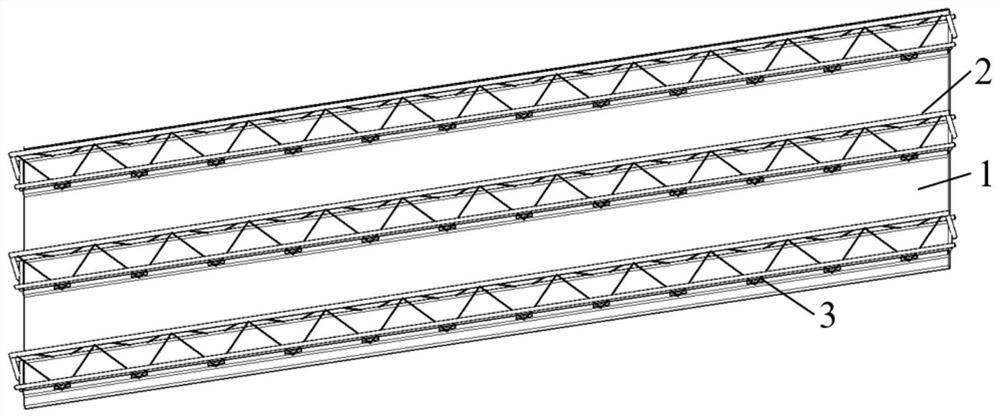

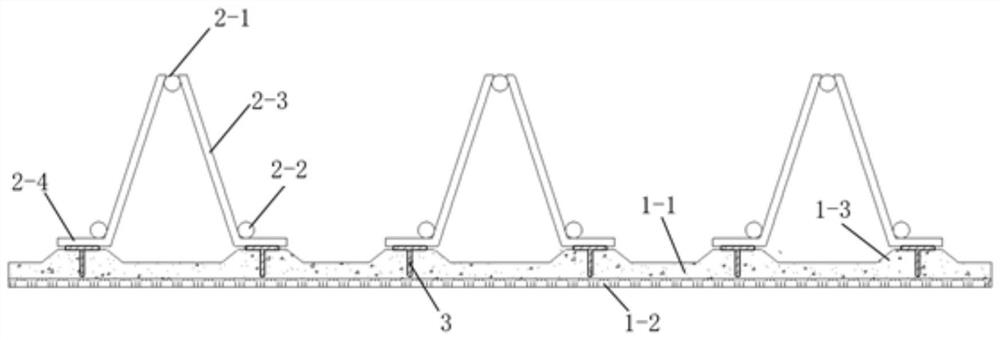

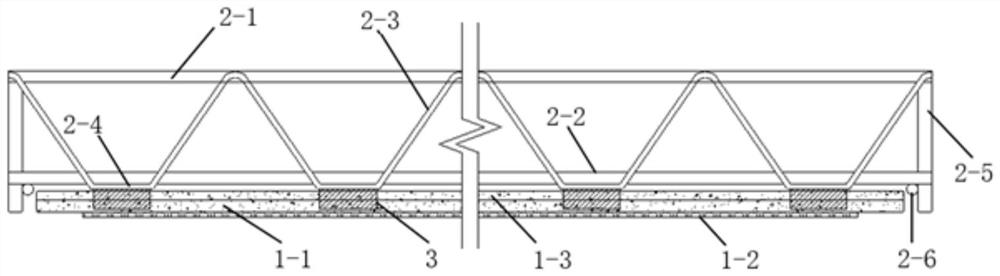

[0042] see Figure 1-Figure 6 , the assembled formwork-free reinforced truss floor deck of this embodiment includes a concrete floor 1, a steel truss 2 and a connector 3, and the concrete floor 1 includes a flat floor part 1-1, and plate ribs 1- 3 and a prefabricated decorative layer 1-2, the steel truss 2 includes upper chord reinforcement 2-1, lower chord reinforcement 2-2, abdominal reinforcement 2-3, abdominal reinforcement bending section 2-4, support vertical reinforcement 2-5 and support The seat cross rib 2-6, the connecting piece 3 includes two parts, an upper fixing part 3-1 and a lower fixing part 3-2.

[0043] Embodiment 1 uses a pre-embedded connector 3 . Firstly, the concrete floor 1 is rolled in the factory, and the lower fixing part 3-2 of the connector 3 is pressed into the plate rib 1-3 according to the designed position before the initial setting of the concrete. After the concrete is solidified, the connector 3 can be connected with the concrete The botto...

Embodiment 2

[0045] see Figure 7-Figure 8 In this embodiment, the assembled formwork-free reinforced truss floor deck includes a concrete floor 1, a steel truss 2 and connectors 3, and the concrete floor 1 includes a flat floor part 1-1 and a prefabricated decorative layer 1-2. The steel bar truss 2 includes upper chord reinforcement 2-1, lower chord reinforcement 2-2, abdominal reinforcement 2-3, support vertical reinforcement 2-5 and support horizontal reinforcement 2-6, and the connector 3 includes an upper fixing part 3-1 and These two parts of lower fixing part 3-2.

[0046] Embodiment 2 adopts the connectors in the form of fasteners. First, the concrete floor 1 is rolled in the factory, and holes are opened at the design position of the connector 3 after the concrete reaches a certain strength; the upper fixing part 3-1 of the connector 3 is in the form of a special nut, that is, the screw hole does not penetrate ( It is a threaded blind hole), one end can be spot welded, and one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com