Smelting method of electrode bar base material for non-protective-atmosphere electroslag remelting of H13 steel

A technology of electroslag remelting and smelting method, which is applied in the field of iron and steel metallurgy, can solve the problems of easy secondary oxidation and low cleanliness of electroslag remelting in non-protective atmosphere, and achieves reduction of inclusion content, high cleanliness, and avoidance of The effect of oxygenation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

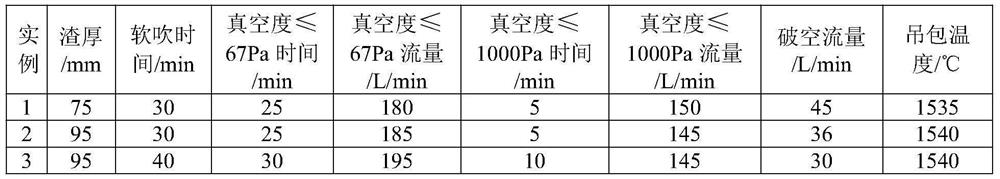

[0043] This embodiment provides three groups of electrode rod base materials for non-protective atmosphere electroslag remelting H13 steel smelted by the smelting method of the present invention, such as Examples 1, 2 and 3. The specific smelting process includes the following steps:

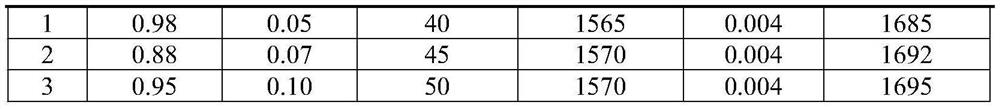

[0044] a. Electric furnace steelmaking: Take scrap steel, pig iron, high-chromium ferro-chromium, high-molybdenum ferro-molybdenum and recarburizer for batching, control carbon and phosphorus content; put lime on the bottom of the furnace and then charge, power transmission and melting; after the furnace charge is fully melted, blow Oxygen, control the [P] content, adjust the voltage and current after the end, and adjust the temperature of the molten steel to tap the steel. The specific control parameters are shown in Table 1.

[0045] Table 1 Process parameters of EAF steelmaking

[0046]

[0047]

[0048] b. LF furnace refining: adding Al wire; adding steel slag and 5kg / ton of steel in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com