Polymer composite material and its preparation method

A composite material and polymer compound technology, applied in the field of new polymer materials, can solve the problems of poor creep resistance of shear thickening materials, single impact protection mechanism and insufficient protective performance of shear thickening materials, and achieve excellent performance. Effects of impact protection performance, raw material safety, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

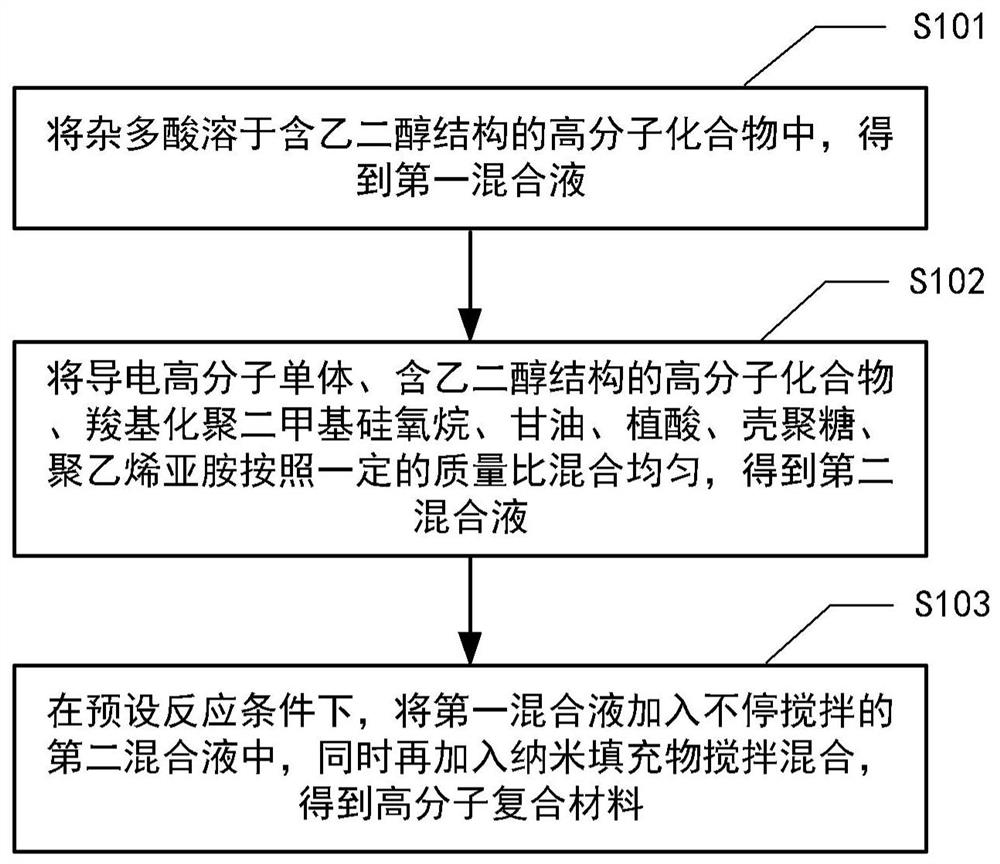

Method used

Image

Examples

Embodiment 1

[0069] Mix 0.5g of silicomolybdic acid and 0.5g of ammonium persulfate in 2g of polyethylene glycol (Mn=300) to obtain the first mixed solution;

[0070] Mix 2g thiophene with 1g polyethylene glycol, 2g carboxylated polymethylsiloxane mixed solution, 0.4g glycerin, 0.15 phytic acid, 0.1g chitosan, and 0.8g polyethyleneimine to obtain the second mixed solution. solution;

[0071] In an ice-water bath reaction device with a reaction temperature of 0-5°C, slowly add the first mixed solution into the second mixed solution while stirring, and form a black lump material after stirring for 6 hours, and then add 0.1g of nano-silica , 0.05g nano-titanium dioxide, 0.05g nano-clay, 0.1g nano-carbon spheres, 0.1g nano-iron oxide, 0.1g nano-cellulose and continue mixing to obtain the final polymer composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com