Co-grinding method for preparing chitosan derivative and PVA blend and application of co-grinding method

A technology of chitosan derivatives and blends, which is applied in the field of co-grinding of chitosan derivatives and PVA blends, can solve the problems of long dissolution time, organic solvent residue, long preparation time, etc., and achieve reaction The effect of shortened time, mild production conditions and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

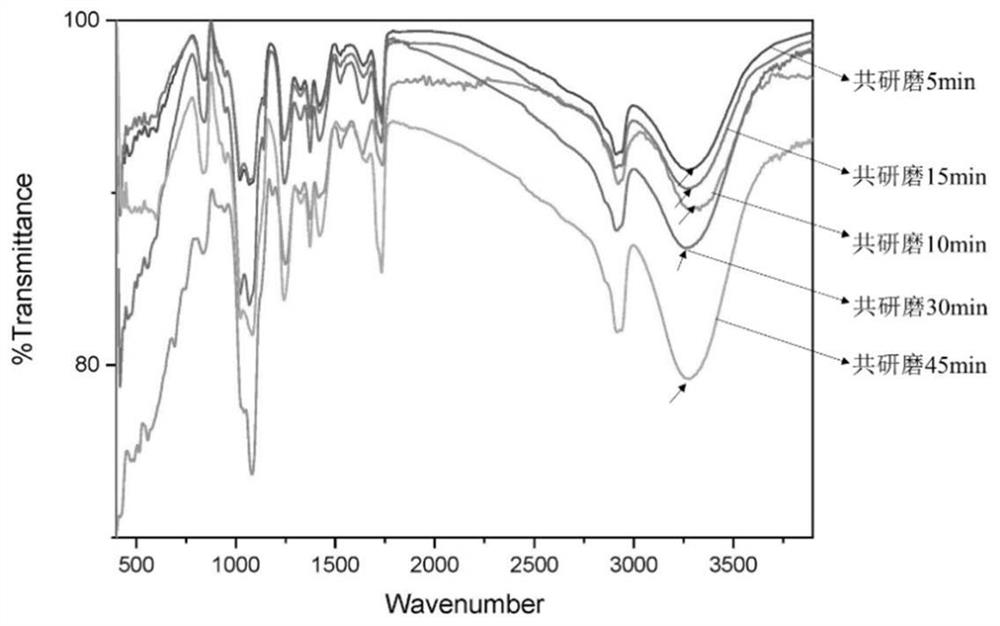

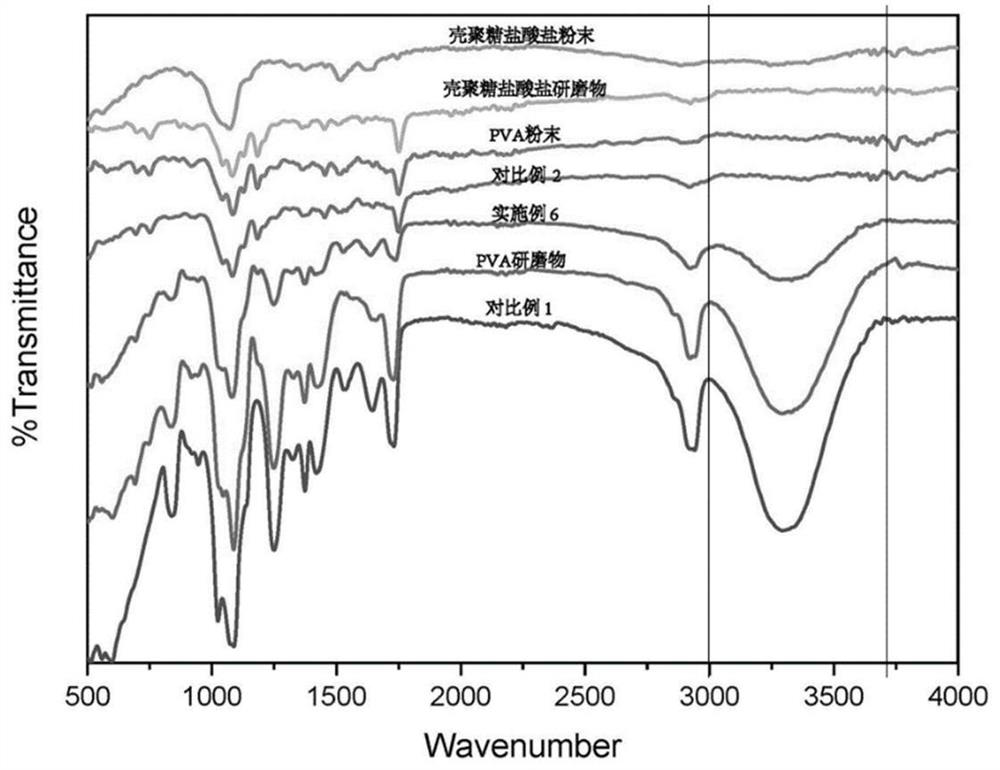

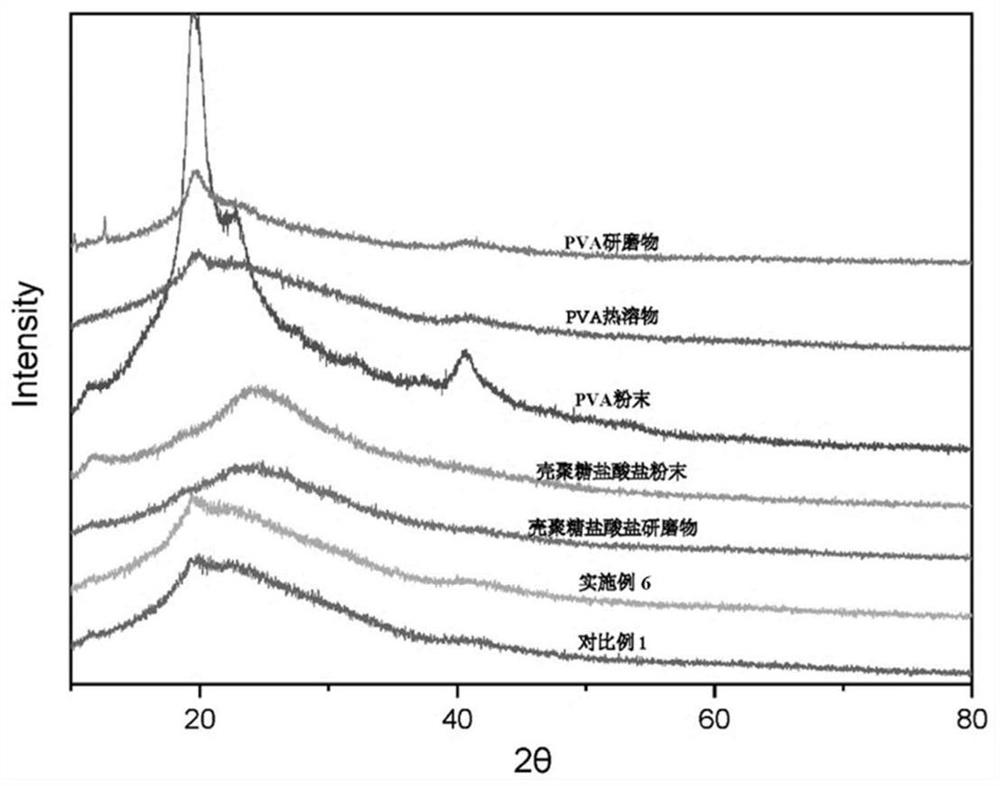

[0040] The screening of embodiment 1 grinding ball diameter

[0041] The co-grinding main body of the present invention is PVA and chitosan derivatives, and the derivatization on the chitosan structure of the latter improves the solubility of molecules, while PVA usually needs to be heated to dissolve. Therefore, the premise of co-grinding under normal temperature conditions in the present invention is that PVA and chitosan derivatives are completely dissolved in the solvent. In the dissolution process of PVA, the diameter of the grinding sphere can directly affect the dissolution time and efficiency, so this implementation The example screened the diameter range of the grinding balls for the dissolution process of PVA resin.

[0042] PVA resin has a certain strength, so the grinding ball should choose a larger diameter (that is, higher quality) to crush the PVA resin. However, when the diameter of the grinding ball is much larger than the particle size of the object to be gr...

Embodiment 2

[0047] The screening of embodiment 2 ball material ratio

[0048] The ball-to-material mass ratio of grinding is also a very critical parameter for grinding efficiency. In this example, 3mm balls are used to grind the PVA 17-90 model for 10 minutes at a speed of 400rpm under the ball-to-material mass ratios of 5:1, 10:1, 20:1, and 30:1, respectively, to evaluate the ball-to-material ratio versus grinding efficiency Impact.

[0049] Table 2 The impact of ball-to-material ratio on PVA dissolution efficiency

[0050]

[0051] In order to highlight the influence of different mass ratios of pellets on the dissolution of PVA, the experiment shortened the grinding time to 10 minutes. It can be seen from the results that when the amount of grinding balls is changed, it has a significant impact on the dissolution efficiency of PVA, and as the proportion of grinding balls reaches a certain range, the effect on promoting the dissolution of PVA also reaches the plateau area, and it w...

Embodiment 3

[0053] Example 3 The screening of co-grinding concentration of PVA and chitosan derivatives

[0054] The concentration of PVA and chitosan derivatives will have a great influence on the preparation process and the properties of the final product. This example preliminarily investigates the possible effects of co-grinding on the conventional concentrations of PVA and chitosan derivatives, such as viscosity, fluidity, and stability. The specific implementation method is as follows. Prepare the PVA grinding solutions with mass concentrations of 10%, 15%, and 20% respectively: use purified water as a solvent, add 50 g of purified water into the mortar, weigh the corresponding PVA powder according to the quality of the purified water and add it to the mortar, according to 10: 1 Ball-to-material mass ratio Weigh 8mm grinding balls, set the grinding speed to 400rpm, and grind for 15 minutes. Chitosan hydrochloride grinds with mass concentrations of 2%, 4%, and 6% were prepared in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com