Pulsating flow enhanced heat exchange ship cooling water system

A technology for cooling water system and strengthening heat exchange, applied in ship propulsion, ship parts, ship construction, etc., can solve the problems of low reliability, unadjustable duty cycle, complex structure of pulsation generating device, etc., and achieve good strengthening effect , the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

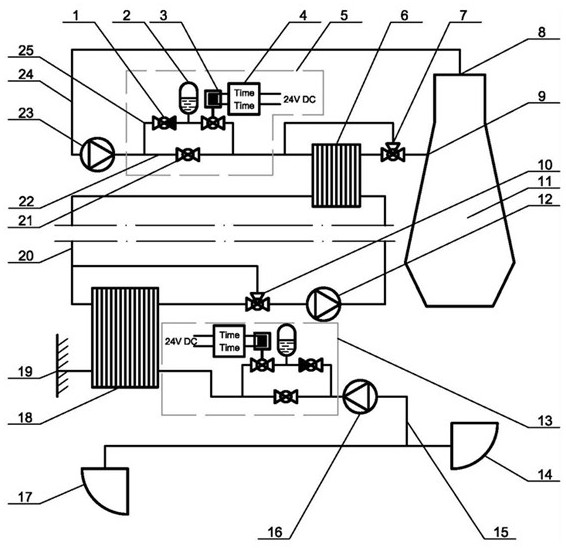

[0022] Such as figure 1 As shown, the pulsating flow enhanced heat exchange ship cooling water system includes a main engine 11, and the main engine 11 is provided with a main engine liner cooling water outlet 8 and a main engine liner cooling water inlet 9, which are respectively used for entering and leaving cooling water, and a high-temperature water circuit 24 The cooling water outlet 8 of the main engine liner, the high-temperature fresh water circulating pump 23, the cooler 6 of the main engine liner, the first three-way valve 7 and the cooling water inlet 9 of the main engine liner, and the side branch connected to the first three-way valve 7 The pipeline can short-circuit the jacket cooler 6 of the main engine; the low-temperature fresh water circuit 20 connects the jacket cooler 6 of the main engine, the central cooler 18, the second three-way valve 10, the low-temperature fresh water pump 12 and the jacket cooler 6 of the main engine in series to form a circuit , the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com