Rotor milling process

A rotor milling and rotor technology, which is applied in the manufacture of stator/rotor body, metal processing, milling machine equipment, etc., can solve problems such as low work efficiency and achieve the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] A rotor milling process, using a rotor milling machine, comprising the steps of:

[0041] S1: Place the unmilled rotor on the transport mechanism, and transport the unmilled rotor to the grabbing position through the transport mechanism.

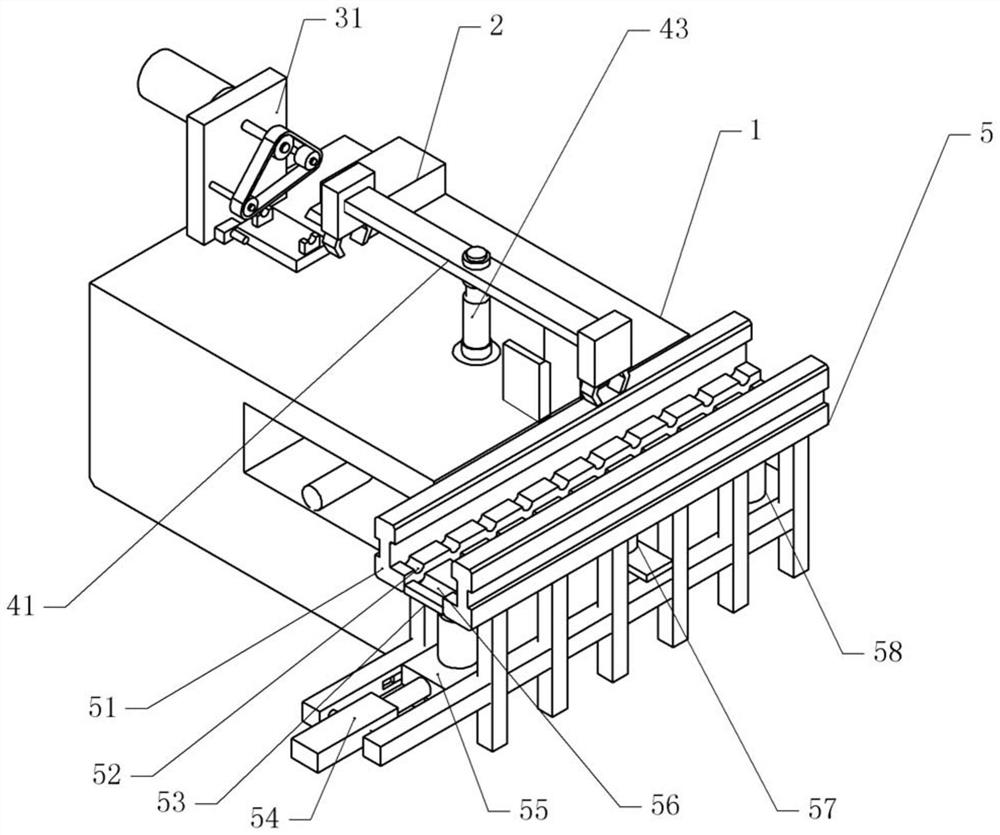

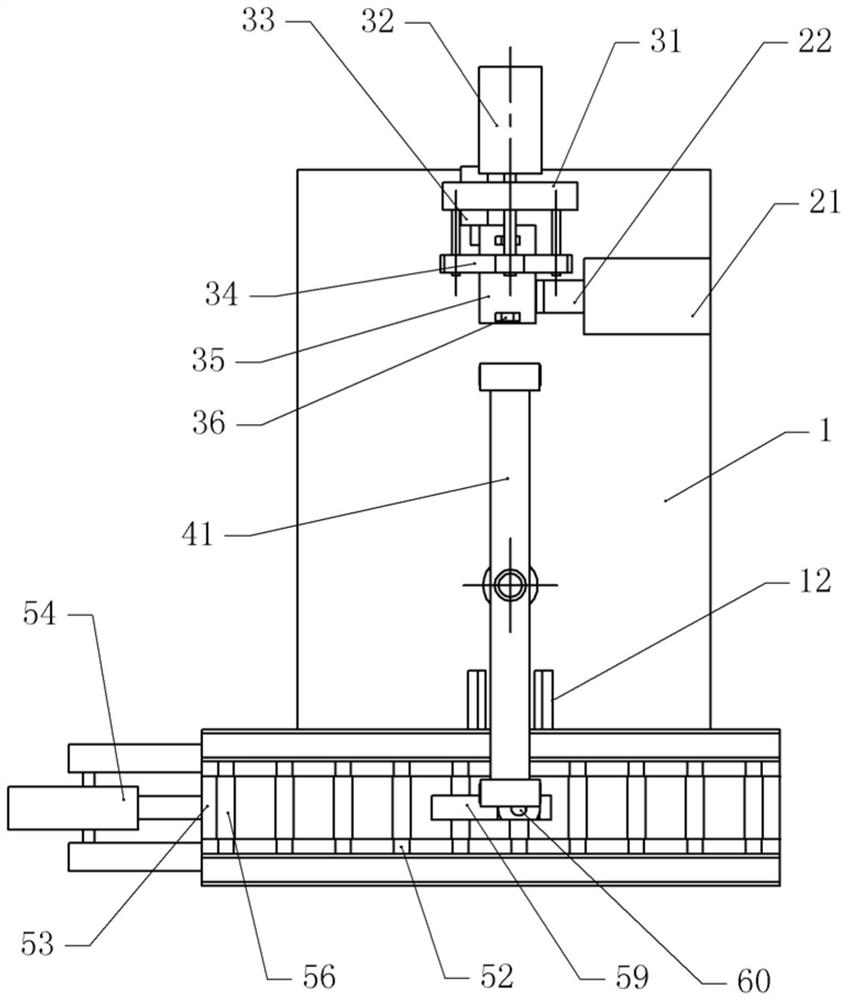

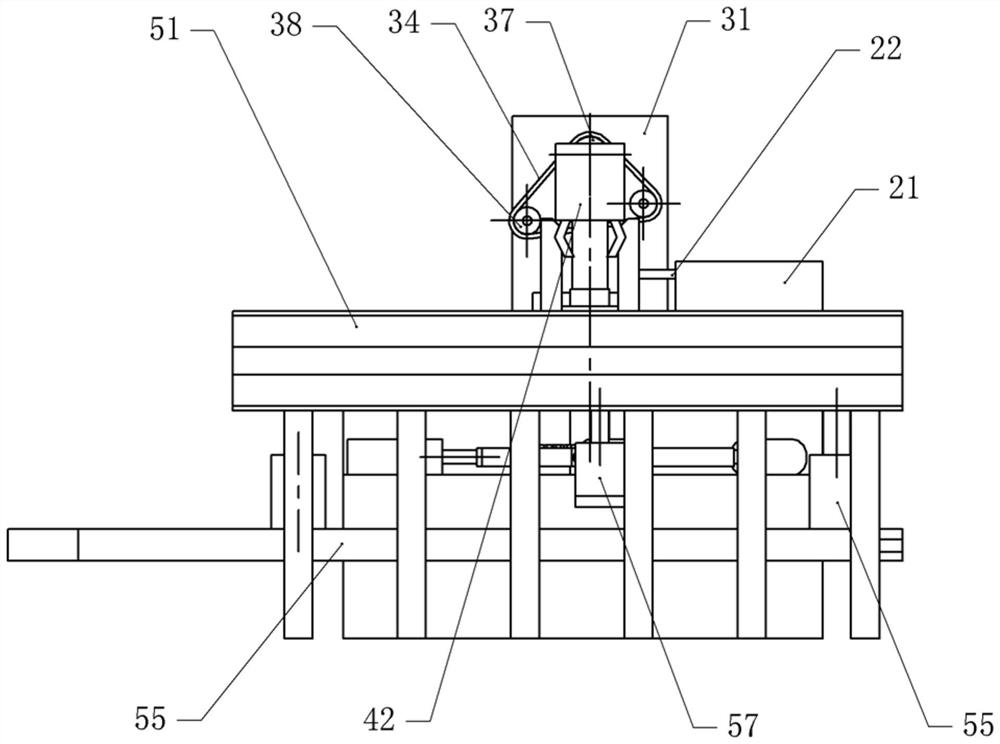

[0042] as attached figure 1 to attach image 3 As shown, the transportation mechanism 5 includes a frame, and the support plate 51 is fixed with bolts on both sides of the upper part of the frame, and the opposite side of the support plate 51 is provided with through grooves. Slot 52. In this embodiment, the longitudinal section of the limiting groove 52 is arc-shaped, and a lifting assembly is arranged between the supporting plates 51 on both sides. The lifting assembly includes a lifting plate 53 and several lifting cylinders 58. The lifting plate 53 is located on both sides Between the support plates 51, a plurality of support grooves 56 are formed on the lifting plate 53, and the longitudinal section of the support grooves 56 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com