Vacuum induction melting and casting process for GH4151 alloy, and ingot mould device

A technology of vacuum induction smelting and vacuum induction furnace, which is applied in the field of alloy smelting, can solve the problems of unreasonable vacuum induction casting process, less research on cracking control, and affecting the process, so as to improve the nucleation rate, reduce the solidification thermal stress, The effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

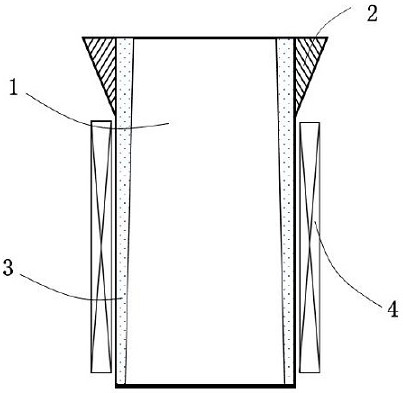

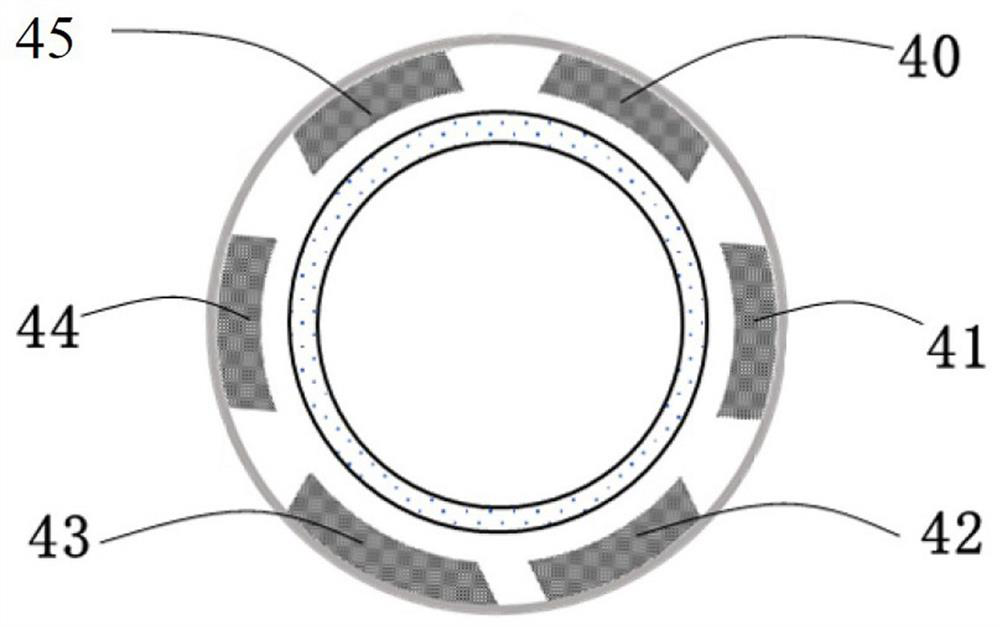

[0055] use figure 1 The ingot mold device shown melts and casts the GH4151 alloy. The formwork of the device is made of ductile iron, and the outer diameter of the formwork is 800mm. The device adopts rock wool as the material of the thermal insulation riser. The diameter of the thermal insulation riser is 1200mm and the height is 500mm. The electromagnetic stirring device of described device is three pairs of induction coils, the first induction coil 40 and the second induction coil 43, the third induction coil 41 and the fourth induction coil 44, the fifth induction coil 42 and the sixth induction coil 45, and Each pair of coils is connected in series as a connection terminal for three-phase alternating current.

[0056] The vacuum induction melting casting process of GH4151 alloy is as follows:

[0057] (1) In terms of mass percentage, GH4151 alloy contains: 0.06%C, 14.5%Co, 11%Cr, 4.5%Mo, 3%W, 0.007%B, 0.02%Zr, 0.55%V, 2.82%Ti, 3.9% Al, 3.28%Nb, Ni;

[0058] (2) Wash ...

Embodiment 2

[0065] Example 2 is basically the same as Example 1, except that in step (1), the GH4151 alloy contains 0.06%C, 14.5%Co, 11%Cr, 4.5%Mo, 3.4%W in terms of mass percentage , 0.007%B, 0.02%Zr, 0.55%V, 3.03%Ti, 3.9%Al, 3.28%Nb, Ni;

[0066] In step (3), the temperature of the alloy melt is 1420°C;

[0067] In step (4), the flow rate of argon gas filling is 215mL / min, and the filling time is 10min.

[0068] In step (5), the casting speed is 13kg / s, and the total casting time is 3.5min.

[0069] The segregation coefficients of Ti, Nb and Mo are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com