Automatic multifunctional machine part machining device

A technology for multi-functional machinery and processing devices, applied in the field of mechanical processing, can solve the problems of reducing the diversity of devices, affecting the practicability of the devices, affecting the working efficiency of the devices, and achieving the effects of improving the degree of automation, improving work efficiency, and improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

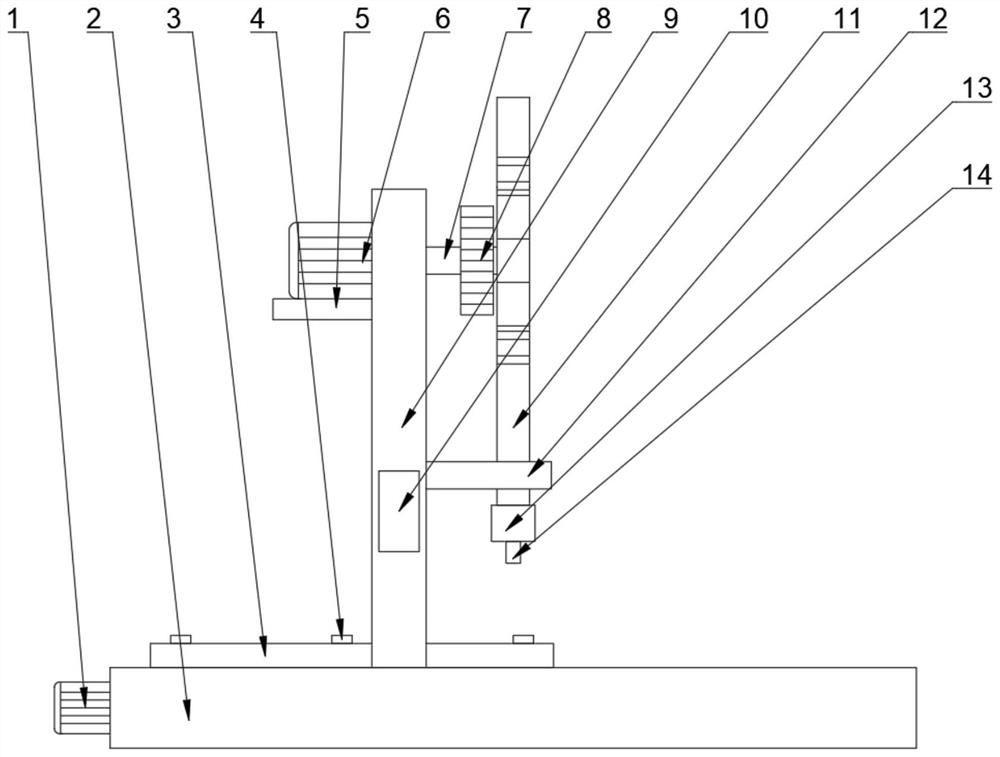

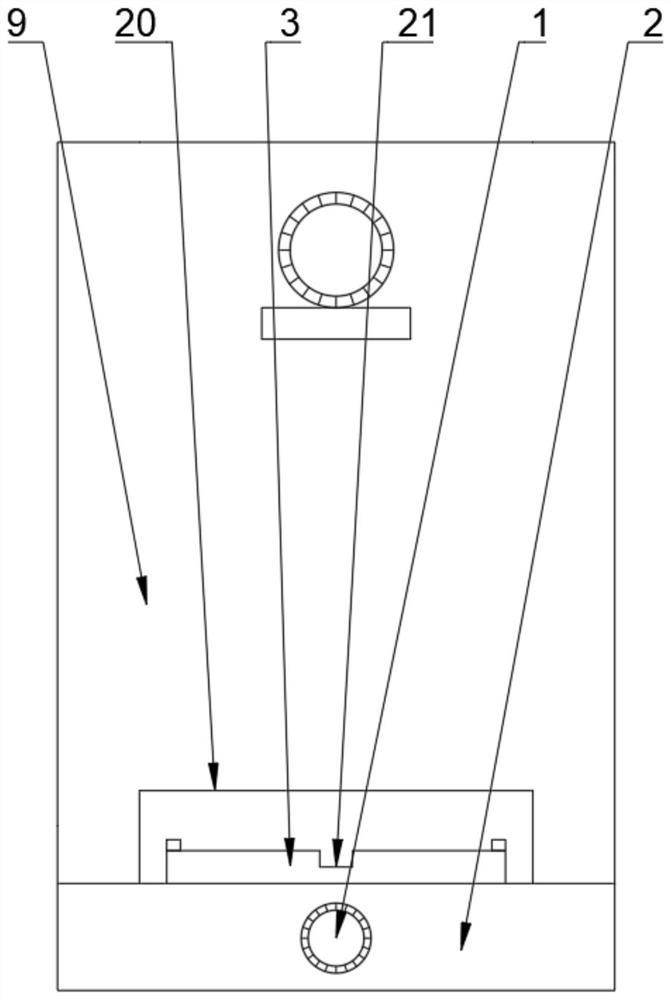

[0025] see Figure 1~5 , in Embodiment 1 of the present invention, an automatic multifunctional mechanical parts processing device includes a base 2, a fixed assembly 4, a moving mechanism, a bracket 9, a lifting mechanism, a controller 10, a punching head mounting assembly 13, and a punching head 14;

[0026] The lifting mechanism includes a lifting motor fixing plate 5, a lifting motor 6, a front driven shaft 7, a front driven gear 8, a lifting rod 11, a limit rod 12, a driving shaft 15, a driving gear 16, a front ring gear 23, a gear Bar 24, the rear driven gear 25, the rear driven shaft 26 and the rear ring gear 27, the lifting motor fixing plate 5 is fixedly connected above the left side of the support 9, and the lifting motor 6 is fixedly connected to the top of the lifting motor fixing plate 5. On the upper surface, the drive shaft 15 is horizontally placed and rotatably connected to the middle part of the bracket 9, the left end of the drive shaft 15 is connected to th...

Embodiment 2

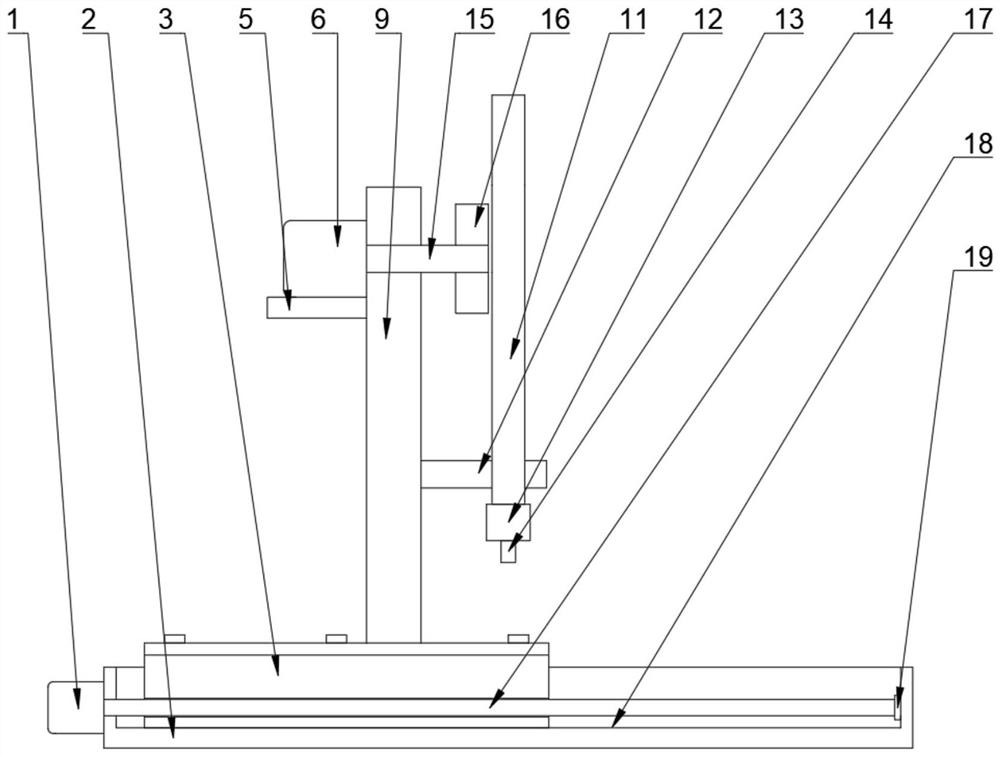

[0028] see Figure 1~5 The main difference between this embodiment 2 and embodiment 1 is that the moving mechanism includes a moving motor 1, a workbench 3, a screw 17 and a rotating seat 19, and the screw 17 is installed horizontally inside the base 2, and is connected with the base The seat 2 is connected in rotation, the rotating seat 19 is fixedly connected to the inner side of the right side of the base 2, the right end of the chute 18 is installed in the rotating seat 19, and is connected in rotation with the rotating seat 19, and the mobile motor 1 is fixedly connected to the bottom of the base 2. On the left side, the driving shaft of the mobile motor 1 is connected to the screw rod 17 through a coupling, and the workbench 3 is installed inside the base 2, and is threaded with the screw rod 17, and is slidingly connected with the base 2; when it needs to move , start the mobile motor 1, and under the action of the mobile motor 1, the screw rod 17 is driven to rotate. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com