Intelligent fuel cell assembling machine and assembling method

A technology for a fuel cell stack and an assembly method, which is applied to fuel cells, circuits, electrical components, etc., can solve the problems of low production efficiency, poor assembly quality, uneven fluid distribution, etc. The effect of even distribution of fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Membrane electrode assembly assembly process:

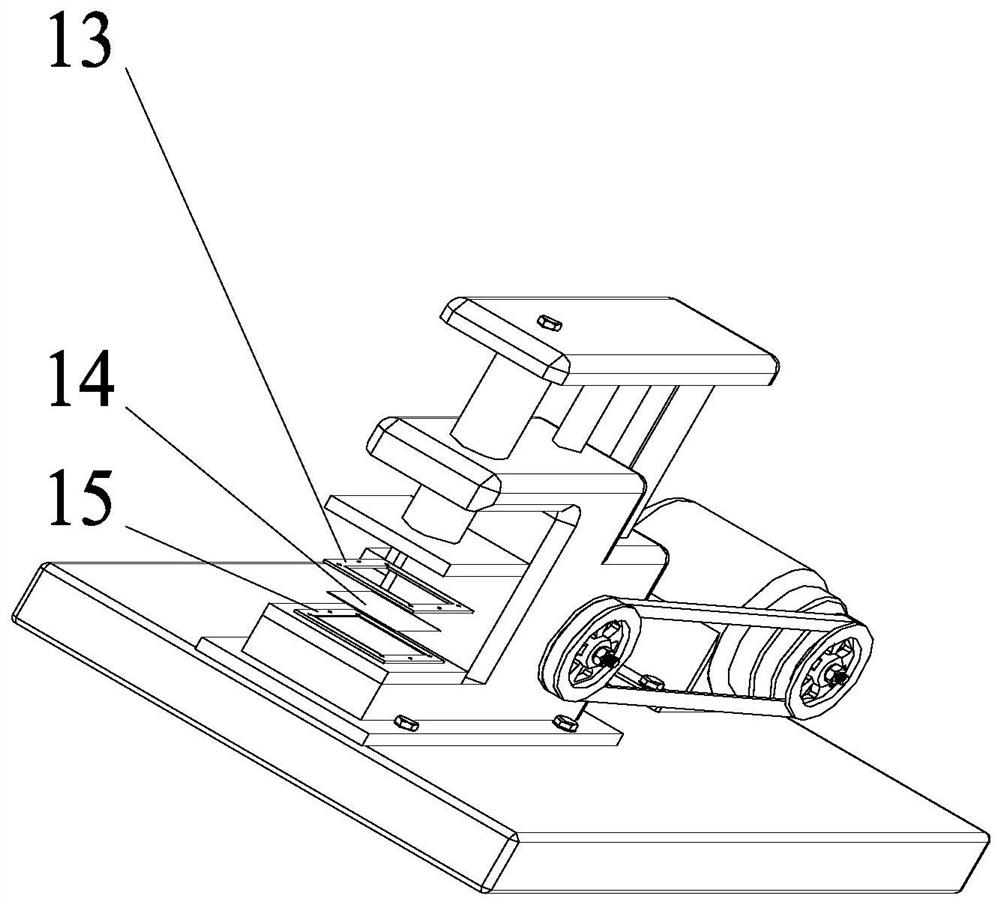

[0068] The membrane electrode assembly is composed of the upper fixed pair 13 of the membrane electrode, the membrane electrode 14 and the lower fixed pair 15 of the membrane electrode. The specific structures of the upper fixed pair 13 and the lower fixed pair 14 of the membrane electrode are as follows: Figure 4 and Figure 5 shown. Before assembling the membrane electrode assembly, first set the working temperature, working pressure, working speed and working time through the display control system 9. According to different technical requirements, the working time is set to 3-10 minutes, and the working temperature is set to 60-80°C. The working pressure is set to 0.4-0.6Mp, and the working speed is set to 0.5-10mm / s. When assembling, first apply sealant to the fronts of the upper fixing pair 13 and 15 of the membrane electrode, put the reverse side of the lower fixing pair 15 of the membrane electrode down on the ra...

Embodiment 2

[0070] Fuel cell stack assembly process:

[0071] The fuel cell stack is mainly composed of the fuel cell lower packaging plate, the fuel cell upper packaging plate, the membrane electrode assembly, the cathode flow plate and the anode flow plate, among which the membrane electrode assembly, the cathode flow plate and the anode flow plate form a single cell. The battery pack unit 17 is composed of n single cells. The fuel cell stack assembly process is image 3 As shown, the upper and lower packaging plates of the fuel cell are as Figure 6 shown. Before the battery pack is assembled, remove the membrane electrode combination auxiliary plate 7 on the intelligent battery assembly machine; set the working temperature, working pressure, working speed and working time through the display control system 9, and set the working time to 3- 5 minutes, the working temperature is set to 60-80°C, the working pressure is set to 0.4-0.6Mp, and the working speed is set to 0.5-10mm / s. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com