Imitated bare concrete protective agent and construction method thereof

A technology imitating fair-faced concrete and fair-faced concrete, applied in coatings, constructions, primers, etc., can solve the problems of decorative surface color difference, decorative surface cracks, clear-water concrete protective agent hollowing and detachment, etc., to ensure the decorative effect and avoid Good effect of cracking and decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

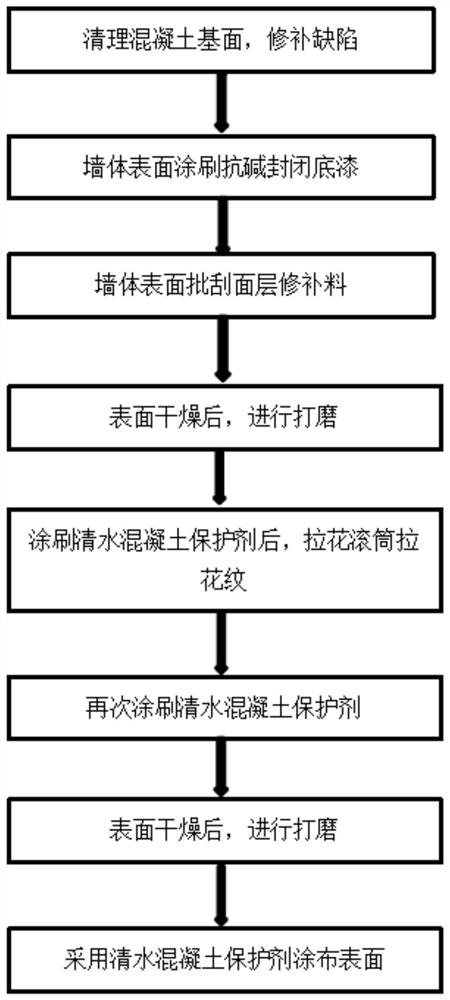

Method used

Image

Examples

Embodiment 1

[0054] According to a kind of imitation fair-faced concrete described in the embodiment of the present invention, it comprises the following components: polymer repair mortar, surface layer repair material, concrete interface repair agent, anti-alkali sealing primer, clear-water concrete protective agent A component and clear water Concrete protectant component B.

[0055] Polymer repair mortar is made of the following raw material ratios by weight: 35% of sulphoaluminate 425 cement, 10% of ordinary 425 Portland cement, 5% of gypsum, 50% of 40 mesh quartz sand, and 0.8kg of early strength agent / ton, polycarboxylate superplasticizer 0.5kg / ton, rubber powder 6kg / ton, low viscosity 400 viscosity cellulose ether 0.2kg / ton.

[0056] The surface repair material is composed of SY-04A high-strength surface repair masterbatch, black cement and white cement. The mass ratio of black cement: white cement: SY-04A high-strength surface repair masterbatch is 2:1:0.04. SY-04A high-strength ...

Embodiment 2

[0073] A kind of imitation clear-water concrete according to the embodiment of the present invention. It comprises the following components: polymer repair mortar, surface layer repair material, concrete interface repair agent, alkali-resistant sealing primer, clear-water concrete protective agent A component and clear water Concrete protectant component B.

[0074] Polymer repair mortar is composed of the following raw material ratios by weight: 32% of sulphoaluminate 425 cement, 10% of ordinary 425 Portland cement, 8% of gypsum, 50% of 60-mesh quartz sand, and 0.8kg of early strength agent / ton, polycarboxylate superplasticizer 0.5kg / ton, rubber powder 8kg / ton, low viscosity 400 viscosity cellulose ether 0.2kg / ton.

[0075]The surface repair material is composed of SY-04A high-strength surface repair masterbatch, black cement and white cement. The mass ratio of black cement: white cement: SY-04A high-strength surface repair masterbatch is 2:1:0.04. The ratio of water to mat...

Embodiment 3

[0091] A kind of imitation clear-water concrete according to the embodiment of the present invention. It comprises the following components: polymer repair mortar, surface layer repair material, concrete interface repair agent, alkali-resistant sealing primer, clear-water concrete protective agent A component and clear water Concrete protectant component B.

[0092] Polymer repair mortar is composed of the following raw materials by weight percentage: 35% of sulphoaluminate 425 cement, 15% of ordinary 425 Portland cement, 5% of gypsum, 45% of 70 mesh quartz sand, and 0.8kg of early strength agent / ton, polycarboxylate superplasticizer 0.5kg / ton, rubber powder 10kg / ton, low viscosity 400 viscosity cellulose ether 0.2kg / ton.

[0093] The surface repair material is composed of SY-04A high-strength surface repair masterbatch, black cement and white cement. The mass ratio of black cement: white cement: SY-04A high-strength surface repair masterbatch is 2:1:0.04. The ratio of water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com