Filler wire static shaft shoulder friction stir welding and additive manufacturing device and method

A technology of additive manufacturing and friction stir, applied in welding equipment, manufacturing tools, additive processing, etc., can solve the problems of unfavorable additive efficiency and additive accuracy, low efficiency of additive manufacturing, and affecting the performance of additive parts. Achieve the effect of being conducive to technology upgrading and equipment replacement, easy and rapid industrial application, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

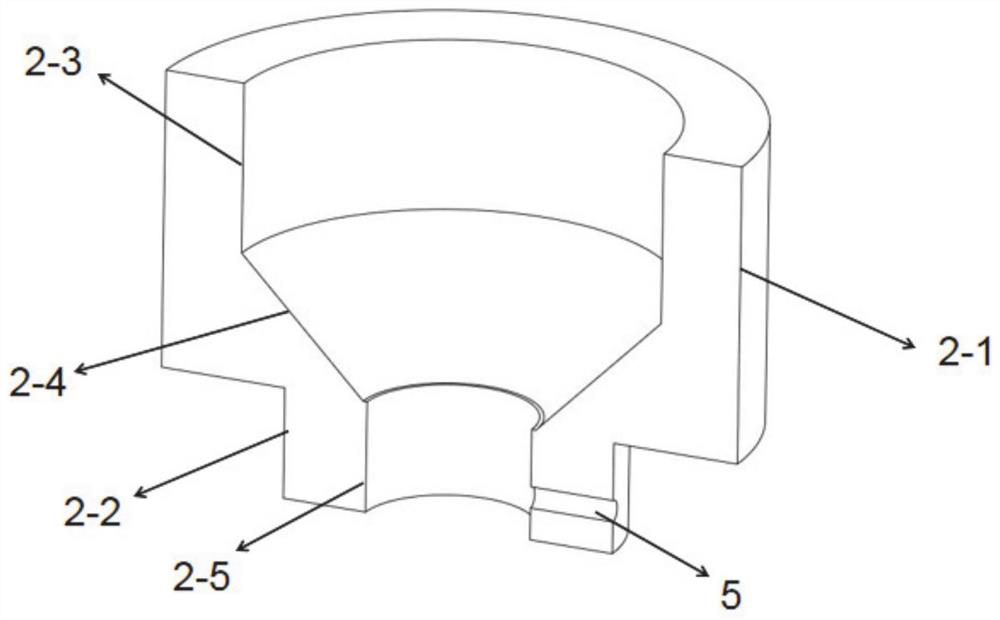

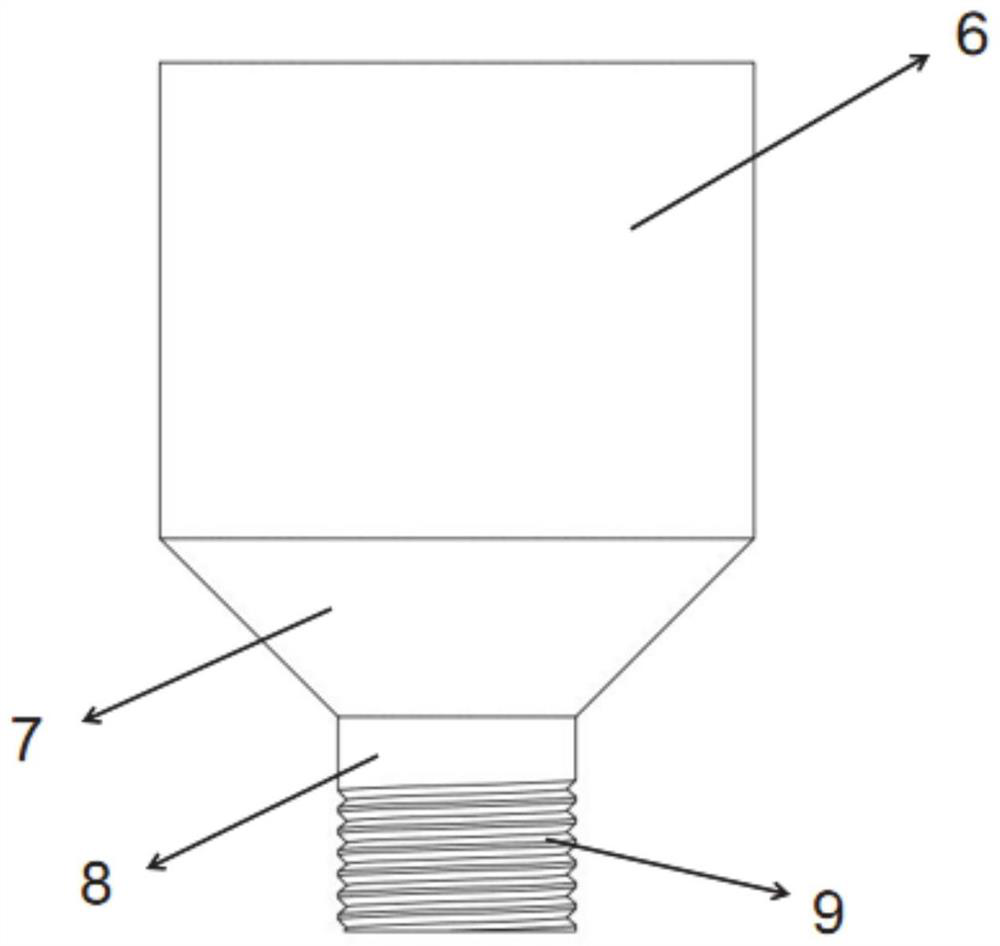

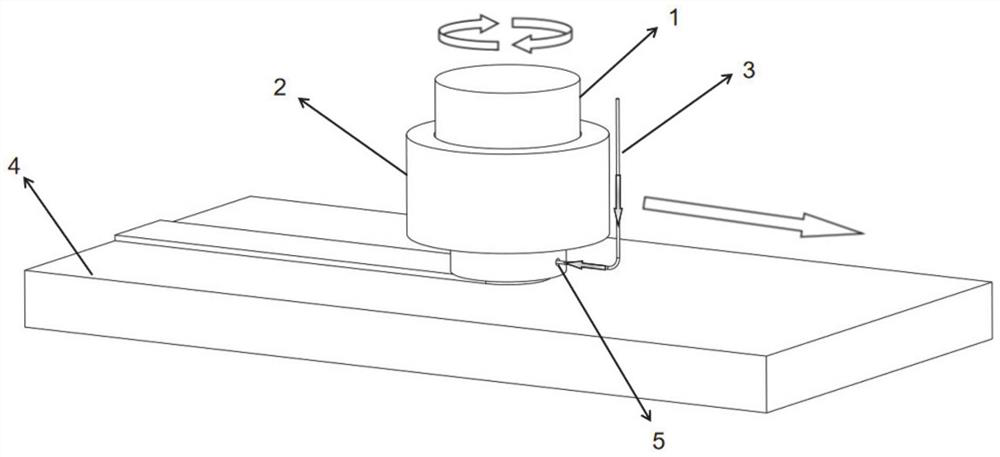

[0044] In a typical implementation of the present application, a static shoulder friction stir welding and additive manufacturing device for filling wire, such as Figure 1-2 As shown, it includes a stirring head 1 and a static shoulder 2 sleeved on the outer periphery of the stirring head. The stirring head is connected to the main shaft of the friction welding machine, and the static shoulder is connected to the three-axis linkage mechanism of the friction welding machine. There is friction stir welding equipment for large-scale transformation, which is conducive to technology upgrading and equipment replacement, and is easy for rapid industrial application.

[0045] The middle position of the static shaft shoulder is provided with a through hole, and the static shaft shoulder is sleeved on the outer periphery of the stirring head through the through hole, and cooperates with the stirring head in a gap, so that the stirring head and the static shaft shoulder are configured to...

Embodiment 2

[0057] This embodiment discloses an additive manufacturing method for the static shoulder friction stir welding and additive manufacturing device described in Embodiment 1, such as Figure 3-4 shown, including the following steps:

[0058] Step 1: Insert the stirring head into the static shaft shoulder, and connect the wire to the wire feeding mechanism;

[0059] Step 2: During additive manufacturing, the stirring needle is rotated and inserted into the matrix 4, the rotation direction of the stirring needle is opposite to that of the thread groove, and the matrix is plastically deformed under the action of the stirring needle to form a stirring zone;

[0060] Step 3: Put the wire material into the wire feeding hole, the wire material passes through the wire feeding hole under the thrust of the wire feeding mechanism, and its end contacts the thread groove of the stirring needle, and thermal plasticization occurs under the action of friction , and then the filament in the t...

Embodiment 3

[0078] This embodiment discloses a method for friction stir welding of a static shaft shoulder filled with wire and friction welding of an additive manufacturing device described in Embodiment 1, including the following steps:

[0079] Step 1: Insert the stirring head into the static shaft shoulder, connect the wire material to the wire feeding mechanism, put the wire material into the wire feeding hole, and make contact with the stirring needle;

[0080]Step 2: During welding, the stirring needle is rotated and inserted into the two workpieces to be welded. The rotation direction of the stirring needle is opposite to that of the thread groove, and the material near the joint surface of the workpiece undergoes plastic deformation under the stirring action of the stirring needle to form a stirring zone;

[0081] Step 3: Under the thrust of the wire feeding mechanism, the wire passes through the wire feeding hole, and its end is in contact with the thread groove of the stirring n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com