Multilayer selective hydrogen permeation composite membrane, and preparation method and application thereof

A composite membrane and selective technology, applied in the field of hydrogen permeation, can solve the problems of hydrogen permeability reduction and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Palladium film / single-layer graphene film / niobium film / single-layer graphene film / palladium film composite film, wherein the thickness of the niobium film is 0.3 mm, the thickness of the palladium film is 100 nm, and the thickness of the single-layer graphene film is 0.334 nm.

[0062] Use 500#, 1000#, 1500#, 2000# sandpaper to mechanically polish the surface of the 0.3mm thick nanocrystalline niobium film, and then use acetone and absolute ethanol for ultrasonic cleaning; then use hydrofluoric acid: concentrated sulfuric acid: lactic acid The mixed acid solution with a volume ratio of 1:3:6 is electrolytically polished, cleaned with deionized water, and dried with cold air for later use.

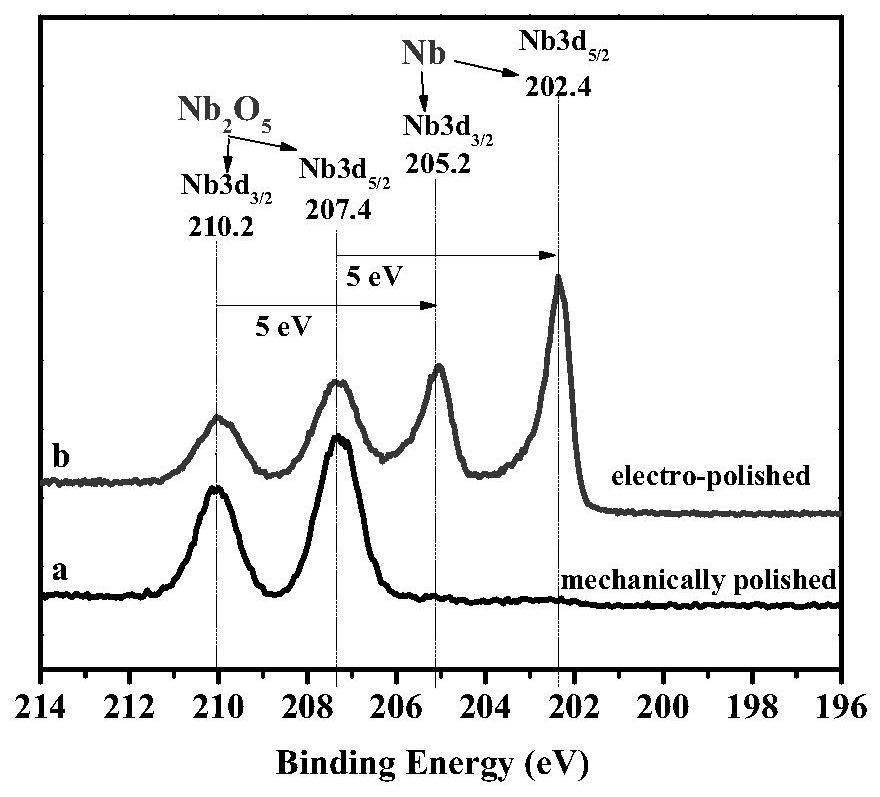

[0063] XPS was used to analyze the surface of niobium film after mechanical polishing and electrolytic polishing, the results are as follows figure 2 As shown, it was found that electrolytic polishing can effectively remove the oxide layer on the surface of the niobium film.

[006...

Embodiment 2

[0069] Palladium-ruthenium film / single-layer graphene film / niobium film / single-layer graphene film / palladium-ruthenium film composite film, wherein the thickness of the niobium film is 0.3 mm, the thickness of the palladium-ruthenium film is 50 nm, and the thickness of the single-layer graphene film is 0.334 nm.

[0070] Use 500#, 1000#, 1500#, 2000# sandpaper to mechanically polish the surface of the 0.3mm thick micro-crystalline niobium film, and then use acetone and absolute ethanol for ultrasonic cleaning; then use hydrofluoric acid: concentrated sulfuric acid: lactic acid The mixed acid solution with a volume ratio of 1:3:6 is electrolytically polished, cleaned with deionized water, and dried with cold air for later use.

[0071] Transfer the single-layer graphene film / polymethyl methacrylate film (Gr / PMMA) to deionized water, and then clamp the niobium film (Nb) with tweezers to cover the single-layer graphene film of Gr / PMMA on the surface The surface of the treated Nb ...

Embodiment 3

[0075] Palladium film / single-layer graphene film / niobium-titanium-nickel film / single-layer graphene film / palladium film composite film, wherein the thickness of niobium-titanium-nickel film is 0.3 mm, the thickness of palladium film is 100nm, and the thickness of single-layer graphene film is 0.334nm.

[0076] Use 500#, 1000#, 1500#, 2000# sandpaper to mechanically polish the surface of the niobium-titanium-nickel alloy film with a thickness of 0.3mm, and then use acetone and absolute ethanol for ultrasonic cleaning; then use hydrofluoric acid: concentrated sulfuric acid: The mixed acid solution with a volume ratio of lactic acid of 1:3:6 is used for electropolishing, cleaned with deionized water, and dried with cold air for later use.

[0077]The single-layer graphene film / polymethyl methacrylate film (Gr / PMMA) was transferred to deionized water, and then the niobium-titanium-nickel alloy film (Nb-Ti-Ni) was clamped with tweezers. The surface of the olefin film is evenly cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com