Pure cotton black cheese dyeing process applied to vinyl sulfone type reactive dye

A reactive dye, vinyl sulfone type technology, applied in the field of cotton dyeing, can solve the problems of color difference between outer yarn and inner yarn, unsuccessful dyeing of natural pure cotton cheese, poor effect, etc. The effect of improving competitiveness and shortening working hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

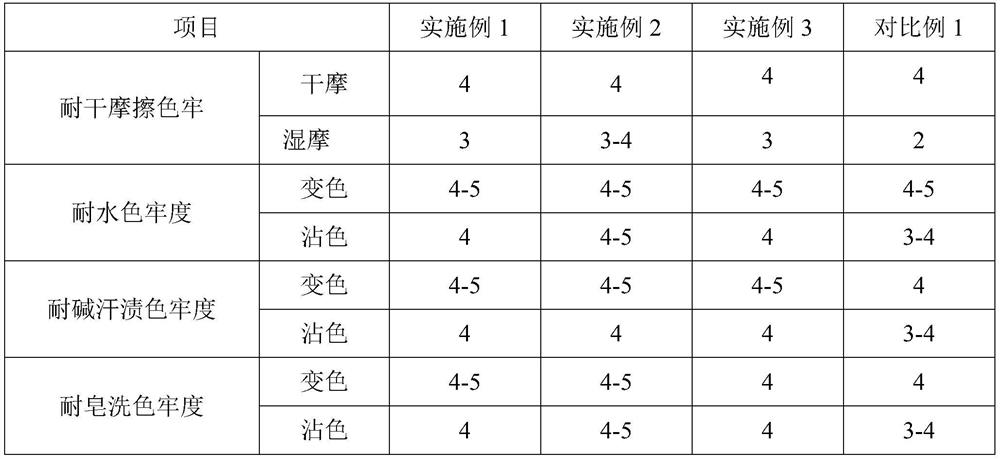

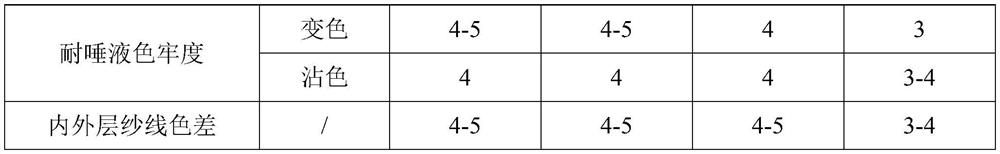

Examples

Embodiment 1

[0035] A pure cotton black cheese dyeing process applied to vinyl sulfone type reactive dyes, comprising the following steps:

[0036] (1) Pre-treatment: add refining agent and soda ash into water, stir until completely dissolved, put it into the main vat with pure cotton cheese, add the water in the main vat to the predetermined water level, cover it, and raise the temperature to 95°C. Continuous circulation (forward 4 reverse 3) for 21 minutes, then drain the water and wait for dyeing. The concentration of refining agent in the main vat is 0.5g / L, and the concentration of soda ash is 2g / L; the refining agent is polyethylene glycol, fatty alcohol The mixed aqueous solution of polyoxyethylene ether and butyl diglycol, its mass concentration is 45wt%, 25wt% and 20wt%;

[0037] (2) Dyeing: add 6 times the weight of pure cotton bobbin, and the aqueous solution of sodium sulfite with a concentration of 100g / L to the master vat, then heat it to 38°C and cycle for 21 minutes, with 4...

Embodiment 2

[0046] A pure cotton black cheese dyeing process applied to vinyl sulfone type reactive dyes, comprising the following steps:

[0047] (1) Pre-treatment: the biorefining agent alkaline pectinase liquid is directly added to the main tank with pure cotton cheese, the water in the main tank is added to the predetermined water 55.0wt%, alkaline pectinase 5.0wt %;

[0048] (2) Dyeing: Add 8 times the weight of pure cotton bobbin, and the aqueous solution of 80g / L anhydrous sodium sulfate into the master vat, then heat to 40°C and cycle for 15 minutes, with 4 positive and negative 3 cycles; then the pure cotton bobbin The active black dyestuff of yarn 8% weight joins in the master vat in 30 minutes, circulates 35 minutes (positive 4 negative 3) at 38 ℃, then is warming up to 60 ℃ with the speed of 1 ℃ / min, circulates 22 minutes (positive 4 reverse 3);

[0049] (3) Color fixation: Dissolve the dyeing partner (ASP) into an aqueous solution, and add it to the main vat within 30 minut...

Embodiment 3

[0057] A pure cotton black cheese dyeing process applied to vinyl sulfone type reactive dyes, comprising the following steps:

[0058] (1) Pre-treatment: add clay-based multi-effect refining agent and soda ash into water, stir until completely dissolved, put it into the main vat with pure cotton bobbin, add the water in the main vat to the predetermined water level and cover it , heat up to 95°C, and circulate continuously (forward 4 reverse 3) for 21 minutes, then drain the water and wait for dyeing. The concentration of refining agent in the main vat is 1g / L, and the concentration of soda ash is 2g / L;

[0059] The refining agent is a mixed aqueous solution of clay dispersion and fatty alcohol polyoxyethylene ether, and its mass concentration is 30.0wt% and 10.0wt%;

[0060] (2) Dyeing: add 5 times the weight of pure cotton bobbin, and the aqueous solution of sodium sulfate with a concentration of 120g / L to the main vat, then heat it to 35°C and cycle for 25 minutes, with 4 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com