A kind of preparation method of high-power far-infrared diamond laser single crystal composite material

A diamond single crystal and composite material technology, which is applied in the field of preparation of high-power far-infrared diamond laser single crystal composite materials, can solve the problems of poor thermal conductivity, multi-layer film structure multi-photon absorption, and affect the high power output of lasers, etc., to solve high heat problems, solving quantum deficit, and the effect of high output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

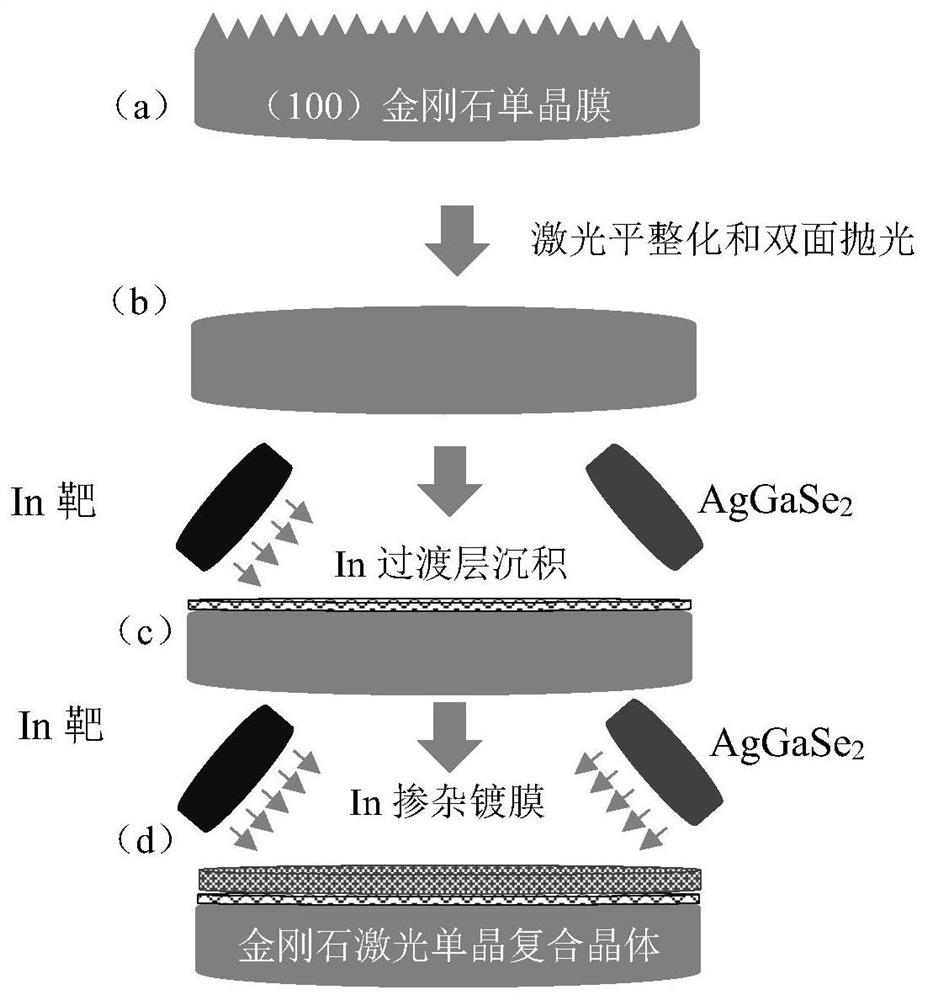

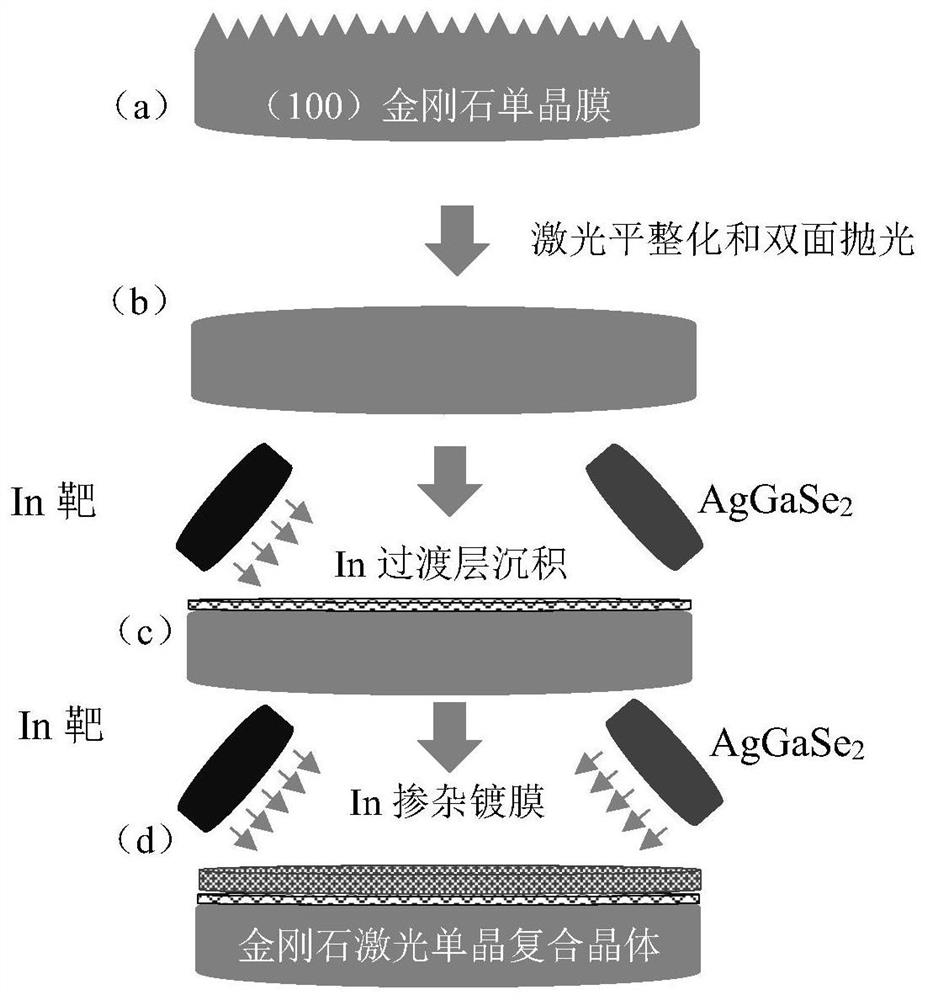

[0036] 1) A method for preparing a high-power far-infrared diamond laser single-crystal composite material, which mainly includes: preparing a high-quality, high-transmittance CVD (100) diamond single-crystal film, and using a microwave plasma chemical vapor deposition system (CVD) to deposit the diamond single-crystal film; The crystal film was grown at a controlled temperature of 900 °C, the growth rate was 6 μm / h, and the deposition time was 217 h. Finally, a 1.3 mm thick as-deposited (100) diamond single crystal film was obtained, such as figure 1 (a).

[0037] 2) Obtaining a double-sided polished diamond film, the specific steps include: firstly, performing laser planarization on the diamond growth surface, excising 0.3 mm thick diamond on the growth surface, removing large diamond particles on the surface, and then carrying out the diamond single crystal film on a single crystal polishing machine. For double-sided polishing, firstly adjust the rotating speed of the polis...

Embodiment 2

[0043] 1) A method for preparing a high-power far-infrared diamond laser single-crystal composite material, which mainly includes: preparing a high-quality, high-transmittance CVD (100) diamond single-crystal film, and using a microwave plasma chemical vapor deposition system (MPCVD) to deposit the diamond single-crystal film; The crystal film was grown at a controlled temperature of 950 °C, the growth rate was 7 μm / h, and the deposition time was 171 h. Finally, a deposited (100) oriented diamond single crystal film with a thickness of 1.2 mm was obtained, such as figure 1 (a).

[0044] 2) Obtaining a double-sided polished diamond film, the specific steps include: firstly, performing laser planarization on the diamond growth surface, excising 0.2 mm thick diamond on the growth surface, removing large diamond particles on the surface, and then performing the diamond single crystal film on a single crystal polishing machine. For double-sided polishing, firstly adjust the polishi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| infrared transmittance | aaaaa | aaaaa |

| infrared transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com