Bi-In-coated Cu foam nanomaterial as well as preparation method and application thereof

A nanomaterial, bi-in technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of hydrogen evolution side reaction, poor product selectivity, low current density, etc., to achieve high Catalytic activity, large specific surface area, effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

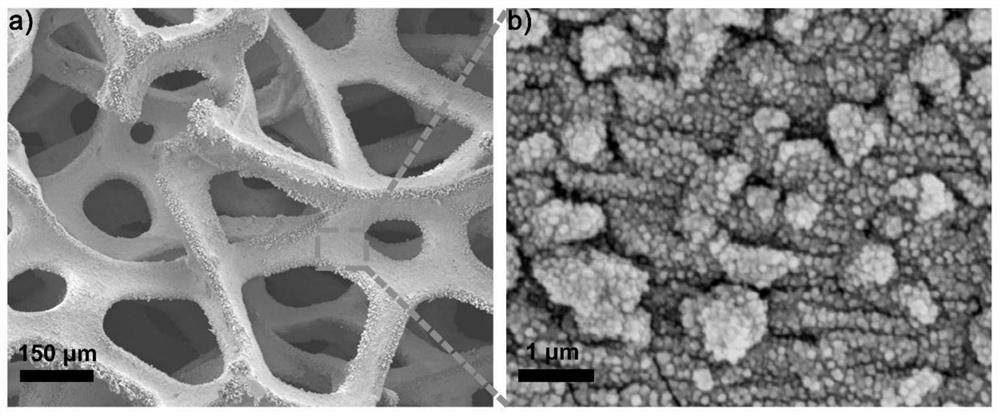

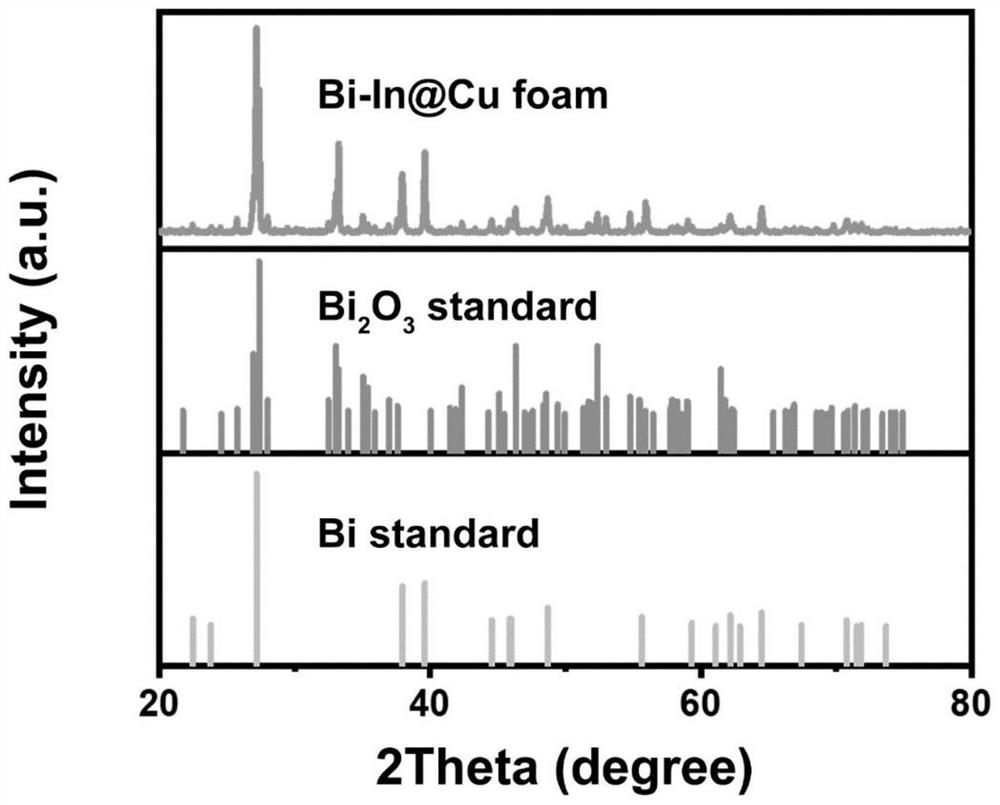

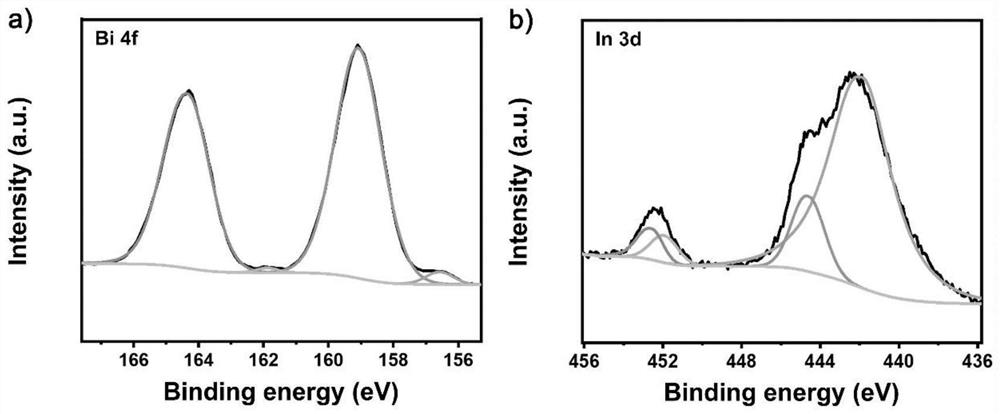

[0034] Preparation of Bi-In@Cu foam nanomaterials:

[0035] (1) Weigh 0.5mmol (0.1931g) of Bi(C 2 h 3 o 2 ) 3 Solid and 0.5mmol (0.1861g) of disodium edetate solid were added to a 100mL beaker, a certain amount of double distilled water was added and stirred at room temperature to dissolve until the solution was clear, then transferred to a 250mL volumetric flask, Recorded as solution A;

[0036] (2) Weigh 0.005mmol (0.0015g) of In(NO 3 ) 3 Add the solid to a 100mL beaker, add a certain amount of double-distilled water and stir at room temperature to dissolve until the solution is clear, then transfer to a 250mL volumetric flask, and record it as solution B;

[0037] (3) Take a 50mL beaker, add 15mL of solution A and 15mL of solution B respectively, and stir evenly at room temperature to obtain mixed solution C;

[0038] (4) Take a piece of 1.0cm×1.5cm×1.0mm copper foam, ultrasonically in 0.5M HCl and double-distilled water for 10 minutes, and then use absorbent paper t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com