A kind of nano-oxide dispersion reinforced heat-resistant zirconium alloy and preparation method thereof

A nano-oxide and dispersion-enhanced technology, which is applied in the field of alloy materials, can solve the problems of poor thermal stability of intermetallic compounds, coarse grains, rapid coarsening of phases and grains, etc., and achieve macro-segregation without components, uniform and fine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

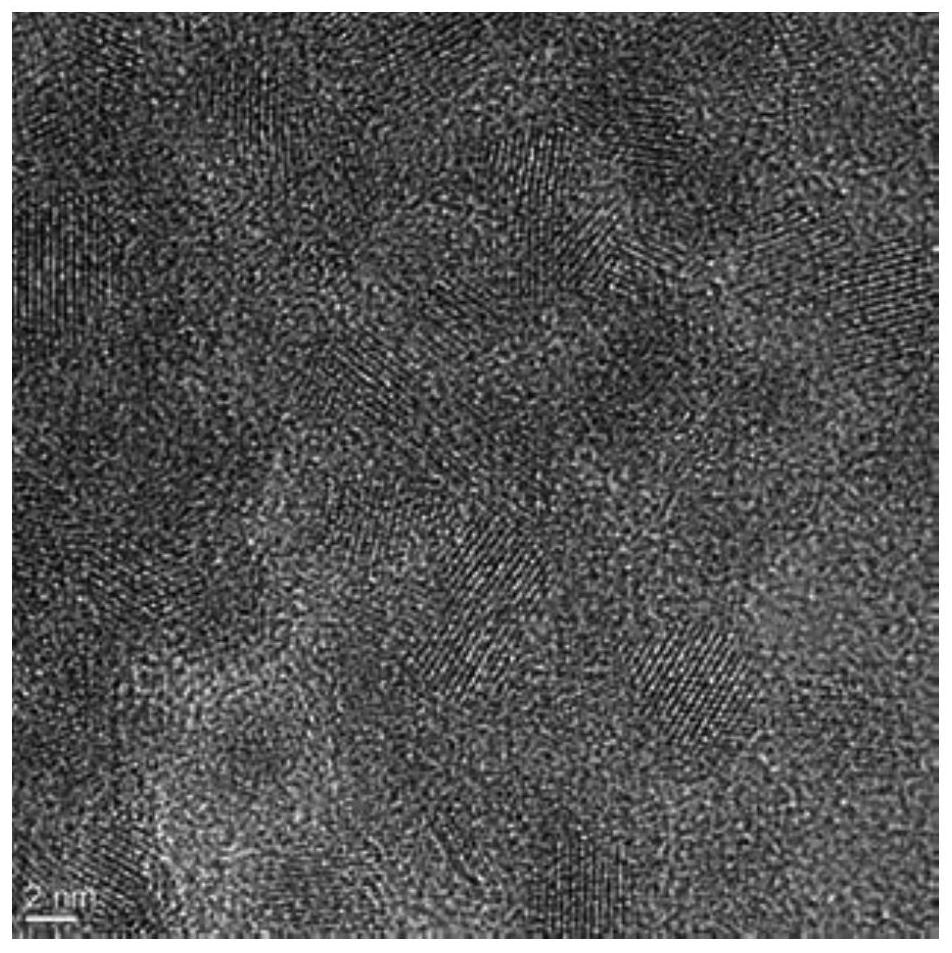

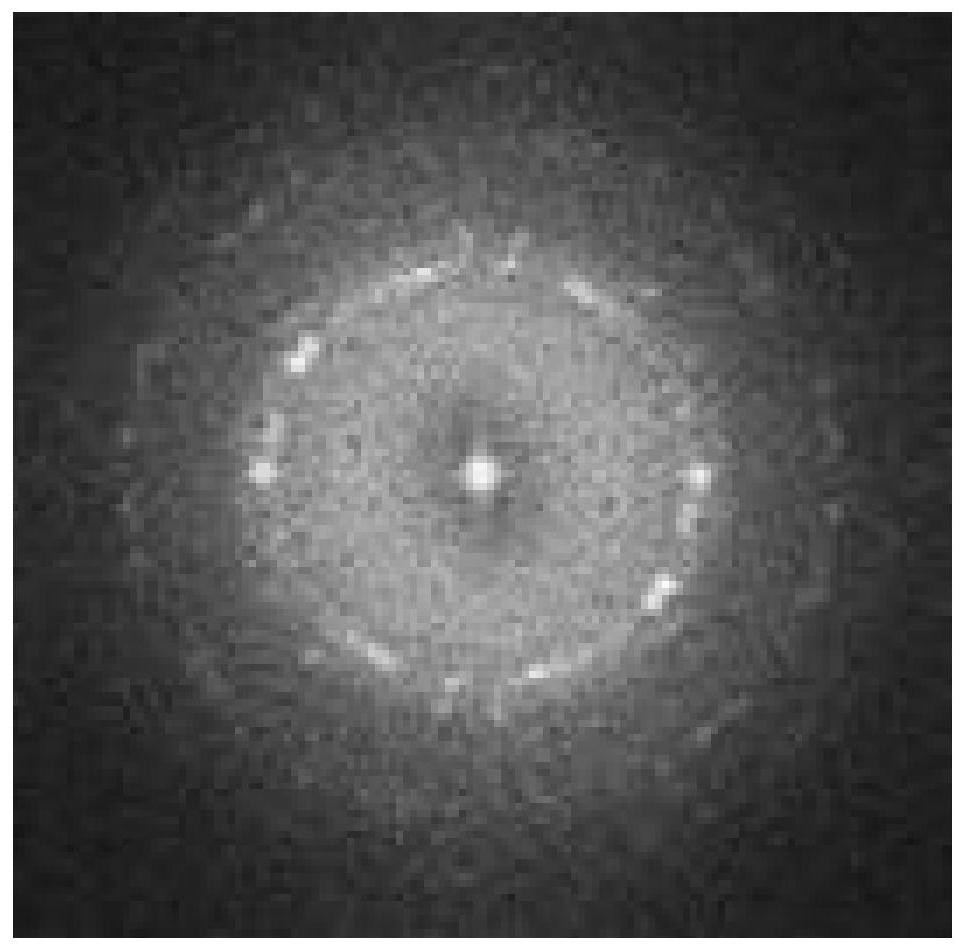

Image

Examples

preparation example Construction

[0035] A preparation method of nano-oxide dispersion reinforced heat-resistant zirconium alloy, comprising the following steps:

[0036] Step S1, the zirconium alloy block is subjected to hydrodehydrogenation treatment to obtain pre-alloyed powder;

[0037] Specifically, the zirconium alloy block includes the following components by weight percentage:

[0038] Sn 1.2-1.6%, Fe 0.2-0.5%, Cr 0.1-0.3%, the balance is Zr and inevitable impurities;

[0039] The hydrogenation adopts a gas tube furnace, and the hydrogenation temperature is 300-500 ℃. After the hydrogenation, it is crushed by ball milling for 5-10 hours and the rotation speed is 300 rpm to obtain the hydrogenated alloy powder; 20µm pre-alloyed powder with hydrogen content not exceeding 100ppm.

[0040] In step S2, the powder material and pre-alloyed powder containing Y, Ti, O elements are put into a high-speed pendulum ball mill, and fully mixed under the protection of an inert gas to obtain a mixed powder;

[0041]...

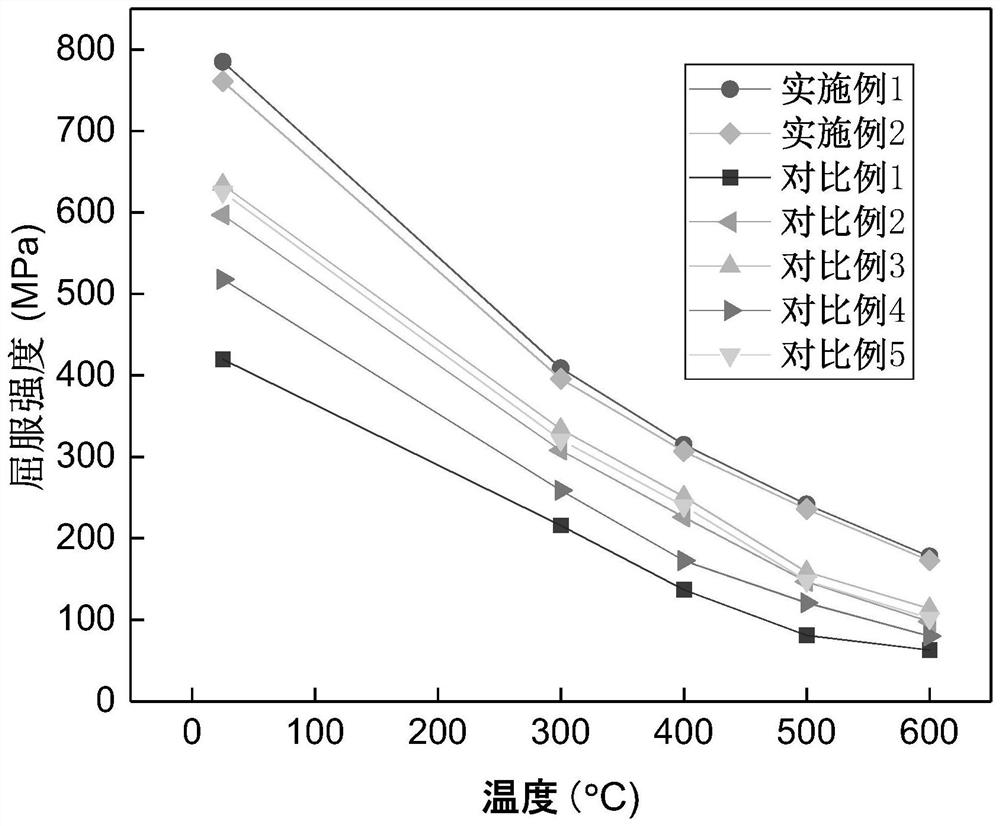

Embodiment 1

[0052] A preparation method of nano-oxide dispersion reinforced heat-resistant zirconium alloy, comprising the following steps:

[0053] Step S1, preparation of pre-alloyed powder: put the zirconium alloy block into a gas tube furnace, hydrogenate it at 500°C to obtain a zirconium hydride alloy block, put the hydride zirconium alloy block into a ball mill, the speed is 300rpm, and the ball milling time is 5h to quickly break it to obtain hydrogenation Alloy powder, the hydrogenated alloy powder is dehydrogenated at 500°C to obtain pre-alloyed powder, the average particle size of the pre-alloyed powder is 5-20 μm, and the hydrogen content does not exceed 100 ppm;

[0054] The zirconium alloy block includes the following components by weight:

[0055] Sn 1.3%, Fe 0.2%, Cr 0.1%, the balance is Zr and inevitable impurities;

[0056] Step S2, powder premixing: the pre-alloyed powder is 0.4wt% TiO 2 Powder, 0.4wt% YH 2 The powder and the pre-alloyed powder are put into a high-spe...

Embodiment 2

[0065] Step S1, preparation of pre-alloyed powder: put the zirconium alloy block into a gas tube furnace, hydrogenate it at 500°C to obtain a zirconium hydride alloy block, put the hydride zirconium alloy block into a ball mill, the speed is 300rpm, and the ball milling time is 5h to quickly break it to obtain hydrogenation Alloy powder, hydrogenated alloy powder is dehydrogenated at 500 ℃ to obtain pre-alloyed powder;

[0066] The zirconium alloy block includes the following components by weight:

[0067] Sn 1.3%, Fe 0.2%, Cr 0.1%, the balance is Zr and inevitable impurities;

[0068] Step S2, powder pre-mixing: the pre-alloyed powder is 0.4wt% Y by weight 2 O 3 Powder, 0.4wt% TiH 2 The powder and the pre-alloyed powder are put into a high-speed pendulum ball mill for pre-mixing, the vibration time is 1h, and the frequency is 1400rpm to obtain the mixed powder;

[0069] Step S3, mechanical alloying: the mixed powder is put into a zirconia ball milling jar, and ball millin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com