Cemented carbide and its preparation method

A cemented carbide, high-quality technology, applied in the field of powder metallurgy, can solve the problems of large tungsten carbide grain size, high price of cemented carbide, uneven grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

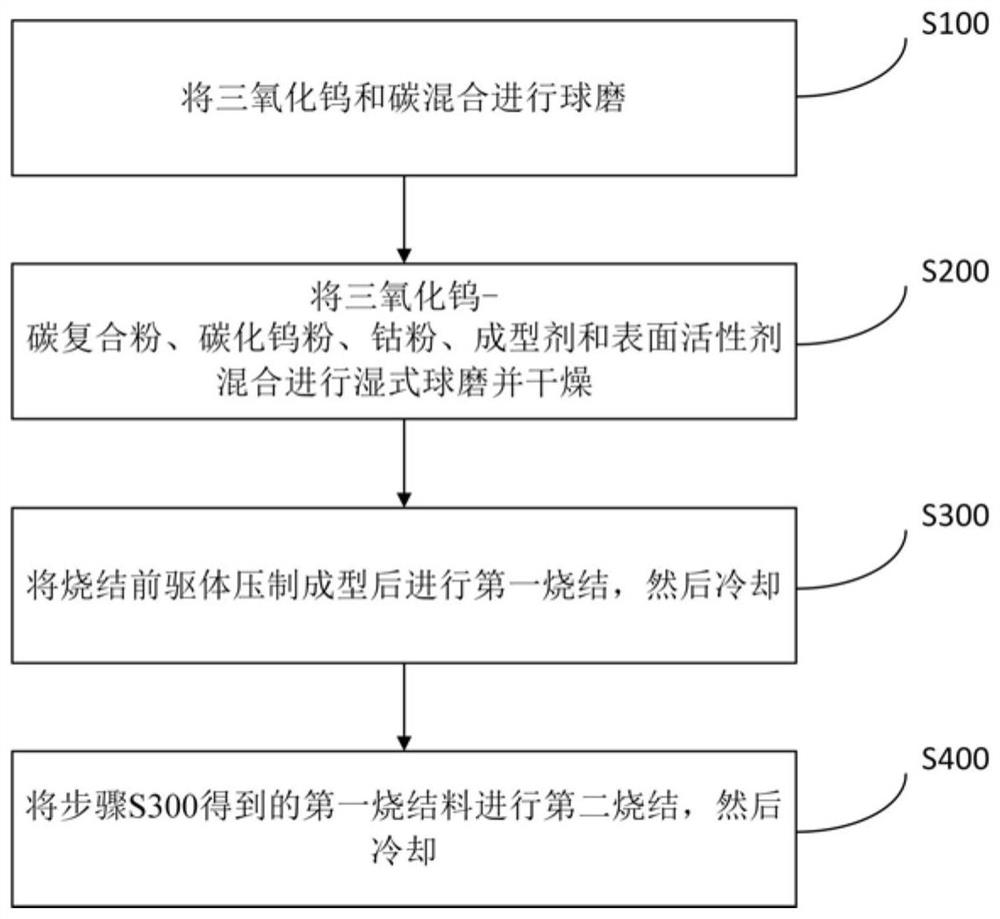

Method used

Image

Examples

Embodiment 1

[0057] Step 1: supply carbon and tungsten trioxide to a ball mill for wet ball milling (the mass of carbon accounts for 10% of the total mass of tungsten trioxide and carbon), the ball milling speed is 350r / min, the ball milling time is 25h, and the ball milling medium is ethanol ( Based on the material composed of 100 g of tungsten trioxide and carbon, the input amount of ethanol is 80 mL), and the ratio of ball to material is 10:1. After the ball milling, the material is vacuum dried, the drying temperature is 80°C, and the drying time is 3h, and the tungsten trioxide-carbon composite powder is obtained after drying;

[0058] Step 2: The tungsten trioxide-carbon composite powder, tungsten carbide powder, cobalt powder, paraffin wax and oleic acid are supplied to a ball mill for wet ball milling (the mass of the tungsten trioxide-carbon composite powder accounts for tungsten trioxide-carbon composite powder and carbon 2% of the total mass of tungsten powder; the mass ratio of...

Embodiment 2

[0062] Step 1: supply carbon and tungsten trioxide to a ball mill for wet ball milling (the mass of carbon accounts for 10% of the total mass of tungsten trioxide and carbon), the ball milling speed is 400r / min, the ball milling time is 20h, and the ball milling medium is ethanol ( Based on the material composed of 100 g of tungsten trioxide and carbon, the input amount of ethanol is 100 mL), and the ratio of ball to material is 10:1. After the ball milling, the material is vacuum dried, the drying temperature is 80°C, and the drying time is 3h, and the tungsten trioxide-carbon composite powder is obtained after drying;

[0063] Step 2: The tungsten trioxide-carbon composite powder, tungsten carbide powder, cobalt powder, paraffin wax and oleic acid are supplied to a ball mill for wet ball milling (the mass of the tungsten trioxide-carbon composite powder accounts for tungsten trioxide-carbon composite powder and carbon 5% of the total mass of tungsten powder; the mass ratio o...

Embodiment 3

[0067] Step 1: supply carbon and tungsten trioxide to a ball mill for wet ball milling (the mass of carbon accounts for 20% of the total mass of tungsten trioxide and carbon), the ball milling speed is 450r / min, the ball milling time is 15h, and the ball milling medium is acetone ( Based on the material composed of 100 g of tungsten trioxide and carbon, the input amount of acetone is 60 mL), and the ratio of ball to material is 8:1. After the ball milling, the material is vacuum-dried, the drying temperature is 60°C, and the drying time is 9h, and the tungsten trioxide-carbon composite powder is obtained after drying;

[0068] Step 2: The tungsten trioxide-carbon composite powder, tungsten carbide powder, cobalt powder, polyethylene glycol and dodecanoic acid are supplied to the ball mill for wet ball milling (the mass of the tungsten trioxide-carbon composite powder accounts for the 10% of the total mass of powder and tungsten carbide powder; the mass ratio of tungsten carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com