Composition for forming heat-conducting lubricant

A technology of composition and lubricant, which is applied in the field of composition forming thermally conductive lubricants, can solve problems such as cumbersome preparation process, unsuitable for large-scale promotion, and poor economic benefits, so as to improve heat transfer coefficient, avoid corrosive damage, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

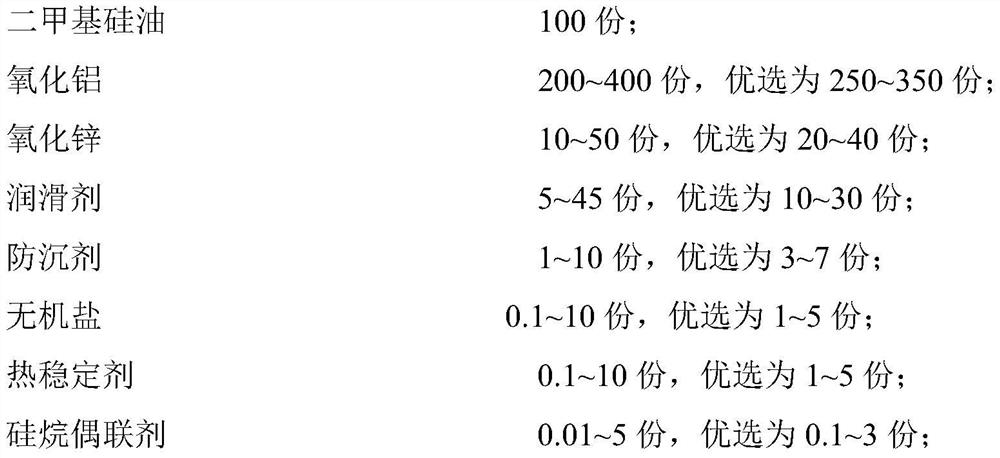

[0063] The raw materials and proportioning that adopt in the present embodiment are as follows:

[0064] Simethicone, 100 parts by weight; Silane coupling agent KH550, 1.65 parts by weight; Aluminum oxide, 300 parts by weight; Zinc oxide, 30 parts by weight; Zinc stearate, 20 parts by weight; Ethyl acetate, 5 parts by weight; Inorganic salt, 3 parts by weight; calcium zinc heat stabilizer, 2 parts by weight.

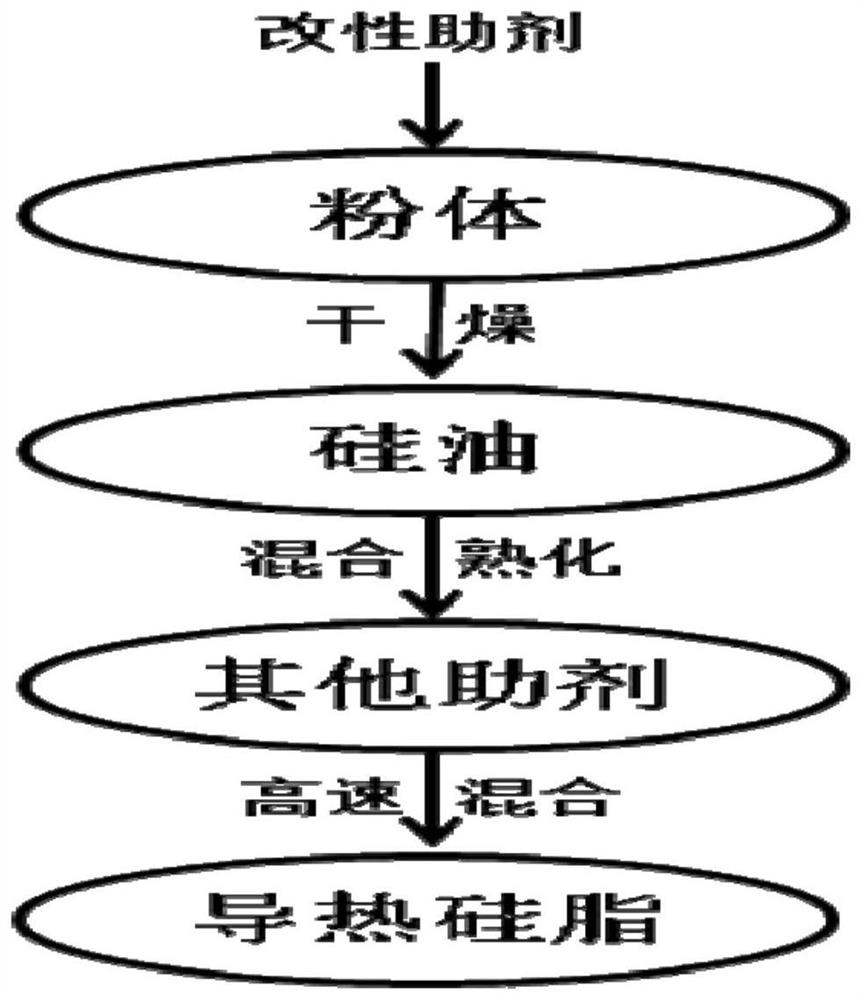

[0065] The process flow chart of this embodiment is as figure 1 As shown, the preparation method taken is as follows:

[0066] 1) Use silane coupling agent KH550 to modify the dried thermally conductive filler powder (namely aluminum oxide and zinc oxide), and the addition amount is 0.5% of the weight of the thermally conductive filler powder. Specifically, firstly, the silane coupling agent Add KH550 into the absolute ethanol which is 25% by weight of the thermally conductive filler powder, and keep stirring. After it dissolves, add the thermally conductive filler pow...

Embodiment 2

[0073] The raw materials and proportioning that adopt in the present embodiment are as follows:

[0074] Simethicone, 100 parts by weight; Silane coupling agent KH550, 1.8 parts by weight; Aluminum oxide, 320 parts by weight; Zinc oxide, 32 parts by weight; Zinc stearate, 21 parts by weight; Ethyl acetate, 5.5 parts by weight; Inorganic salt, 3.5 parts by weight; calcium zinc heat stabilizer, 2.5 parts by weight.

[0075] The preparation method that present embodiment takes is identical with embodiment 1.

[0076] The prepared thermal lubricant was tested, and the results showed that the thermal conductivity of the thermal lubricant could reach 0.98W / m·K; the rolling friction coefficient of the thermal lubricant was 0.06%.

Embodiment 3

[0078] The raw materials and proportioning that adopt in the present embodiment are as follows:

[0079] Simethicone, 100 parts by weight; Silane coupling agent KH550, 1.5 parts by weight; Aluminum oxide, 280 parts by weight; Zinc oxide, 28 parts by weight; Zinc stearate, 19 parts by weight; Ethyl acetate, 4.5 parts by weight; Inorganic salt, 2.5 parts by weight; calcium zinc heat stabilizer, 1.5 parts by weight.

[0080] The preparation method that present embodiment takes is identical with embodiment 1.

[0081] The prepared thermal lubricant is tested, and the results show that the thermal conductivity of the thermal lubricant can reach 0.96W / m·K; the rolling friction coefficient of the thermal lubricant is 0.08%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com