Preparation method and application of temperature-sensitive nano silicon dioxide surfactant with asymmetric structure

A nano-silica, asymmetric structure technology, applied in chemical instruments and methods, chemical dehydration/demulsification, chemical/physical processes, etc., can solve the problem of slow reaction speed, easy oxidation of cuprous bromide, and influence on reaction Stability and other issues, to achieve the effect of easy separation, beneficial to crude oil transportation, convenient use and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

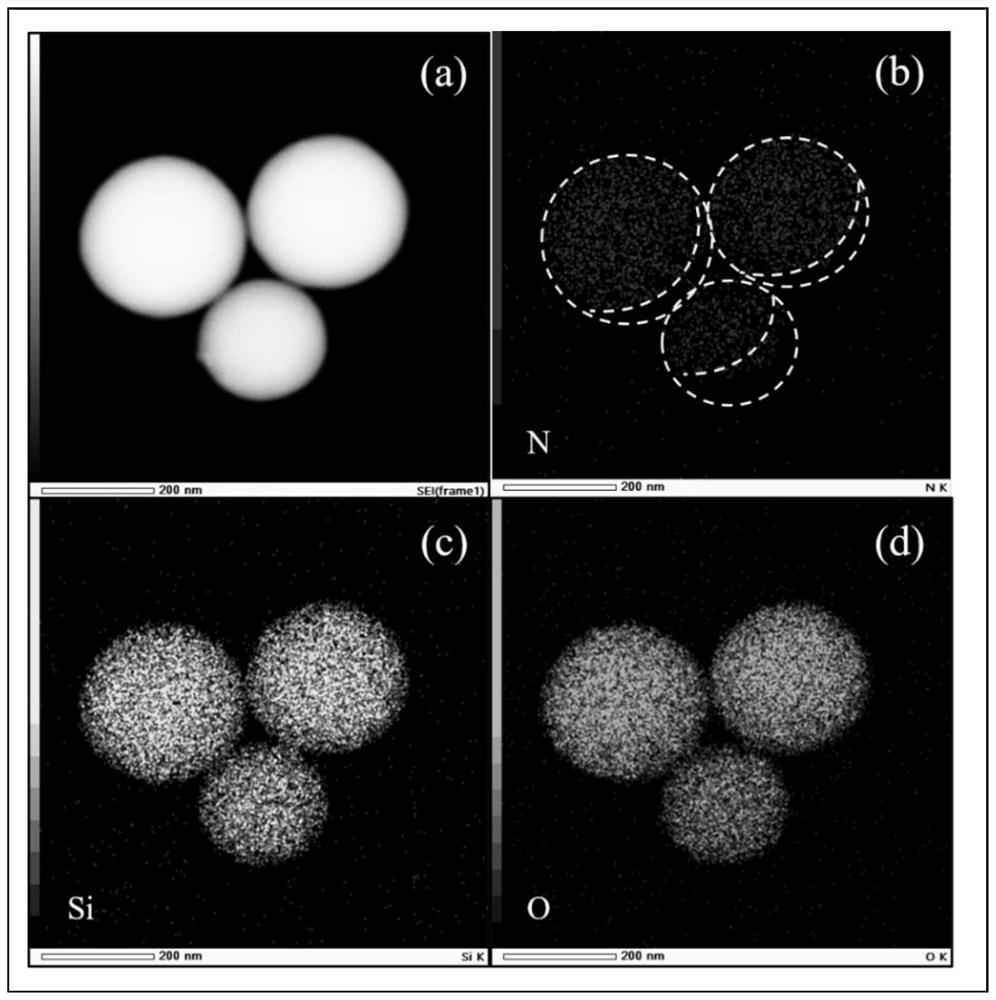

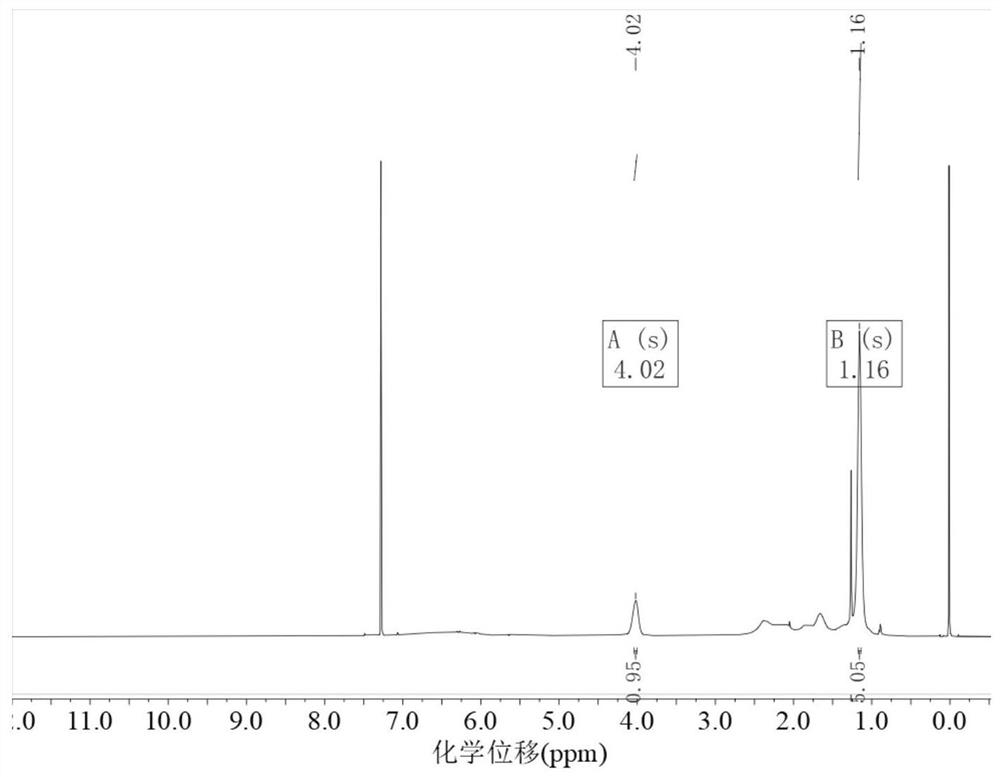

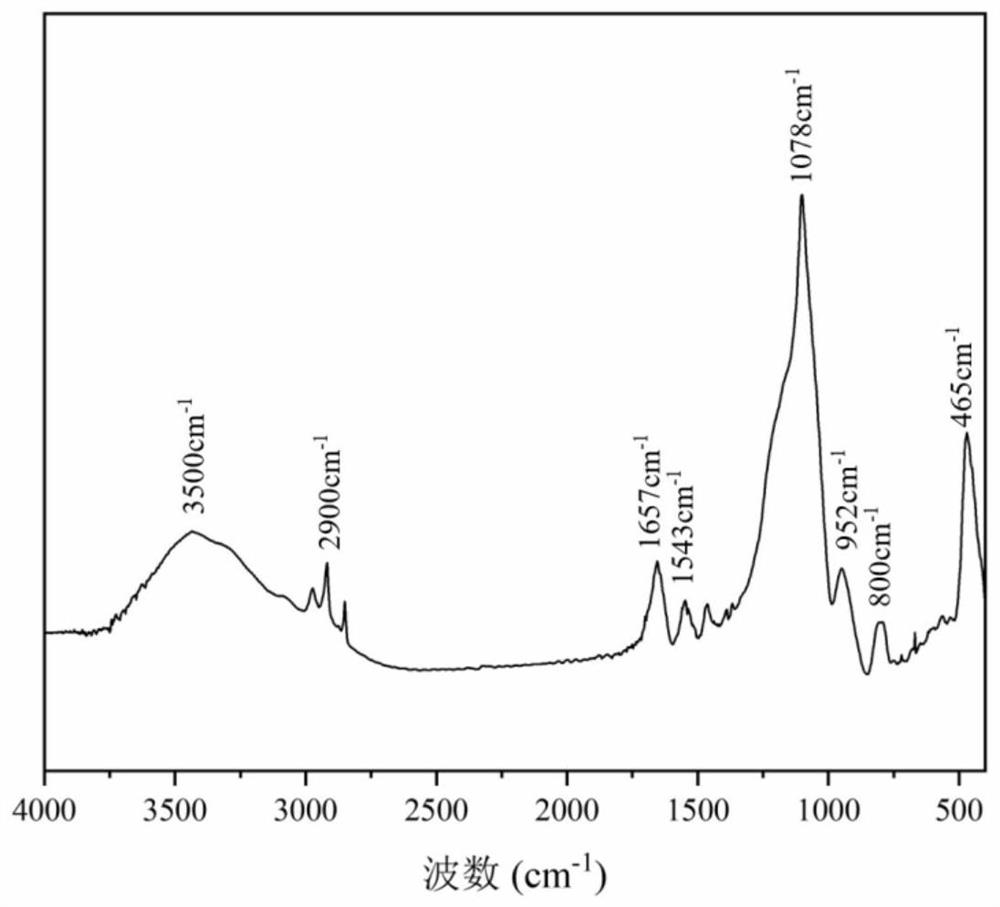

[0056] This example provides an asymmetric structure of HO-SiO 2 -PNIPAM surfactant, it is synthesized by the following steps:

[0057] At room temperature, add ammonia water (25wt%, 20mL) and ethanol (125mL) into the round bottom flask. The mixture was stirred at 700 rpm for 20 min. Then TEOS (8 mL) was added dropwise using a constant pressure dropping funnel. After stirring for 20h, centrifuge at 8000rpm to separate SiO 2Nanoparticles. Wash with absolute ethanol and deionized water three times respectively, and dry the product under vacuum at 50°C for 12 hours. SiO 2 Nanoparticles were treated in piranha solution at 90°C for 2h. After the reaction, it was filtered with suction, washed three times with deionized water, and dried in vacuum at 50°C for 12 hours.

[0058] Take 0.5g of pretreated SiO 2 The particles were added to 20mL of distilled water, and 4mL of DDAB solution (60mg / L) was added, followed by ultrasonic analysis for 30min. The above mixed solution was p...

Embodiment 2

[0072] This example provides an asymmetric structure of HO-SiO 2 -PNIPAM surfactant, it is synthesized by the following steps:

[0073] At room temperature, add ammonia water (25wt%, 20mL) and ethanol (125mL) into the round bottom flask. The mixture was stirred at 700 rpm for 20 min. Then TEOS (8 mL) was added dropwise using a constant pressure dropping funnel. After stirring for 20h, centrifuge at 8000rpm to separate SiO 2 Nanoparticles. Wash with absolute ethanol and deionized water three times respectively, and dry the product under vacuum at 50°C for 12 hours. SiO 2 Nanoparticles were treated in piranha solution at 90°C for 2h. After the reaction, it was filtered with suction, washed three times with deionized water, and dried in vacuum at 50°C for 12 hours.

[0074] Take 0.5g of pretreated SiO 2 The particles were added to 20mL of distilled water, and 4mL of DDAB solution (60mg / L) was added, followed by ultrasonic analysis for 30min. The above mixed solution was ...

Embodiment 3

[0079] This example provides an asymmetric structure of HO-SiO 2 -PNIPAM surfactant, it is synthesized by the following steps:

[0080] At room temperature, add ammonia water (25wt%, 20mL) and ethanol (125mL) into the round bottom flask. The mixture was stirred at 700 rpm for 20 min. Then TEOS (8 mL) was added dropwise using a constant pressure dropping funnel. After stirring for 20h, centrifuge at 8000rpm to separate SiO 2 Nanoparticles. Wash with absolute ethanol and deionized water three times respectively, and dry the product under vacuum at 50°C for 12 hours. SiO 2 Nanoparticles were treated in piranha solution at 90°C for 2h. After the reaction, it was filtered with suction, washed three times with deionized water, and dried in vacuum at 50°C for 12 hours.

[0081] Take 0.5g of pretreated SiO 2 The particles were added to 20mL of distilled water, and 4mL of DDAB solution (60mg / L) was added, followed by ultrasonic analysis for 30min. The above mixed solution was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com