Method for preparing ceramic microspheres by adopting direct titration molding technology

A technology of ceramic microspheres and titration, which is applied in ceramic molding machines, manufacturing tools, and liquid droplets and granulation, etc., can solve the problems of low uniformity of microsphere molding, difficult automatic control, and cumbersome production process. Achieve automatic control, efficient automatic control, good internal uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

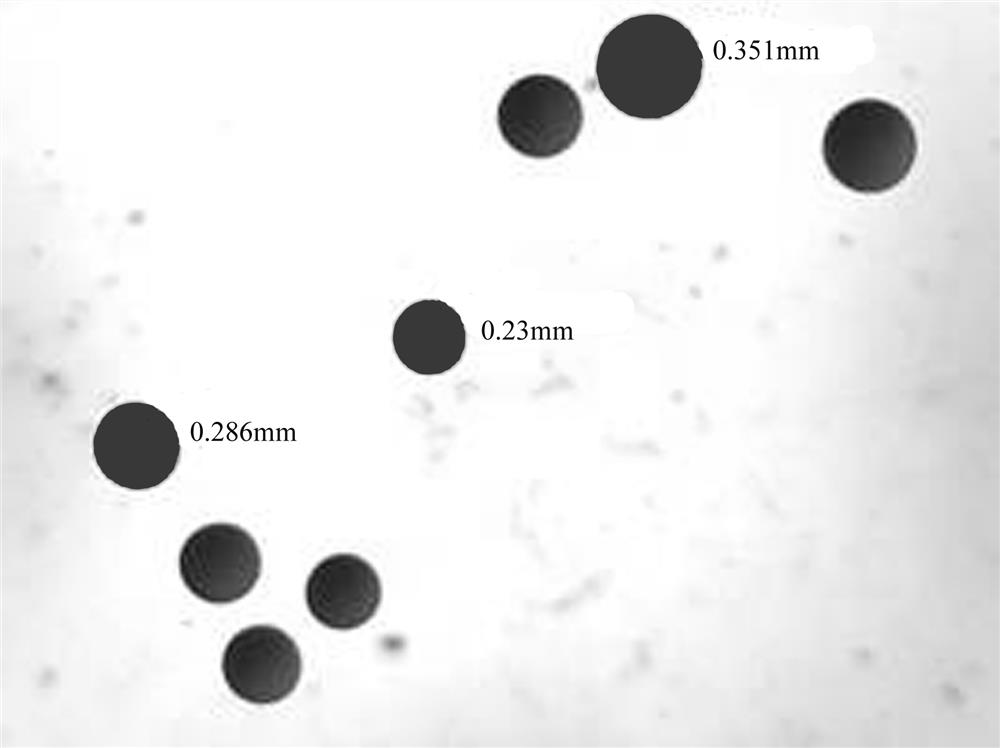

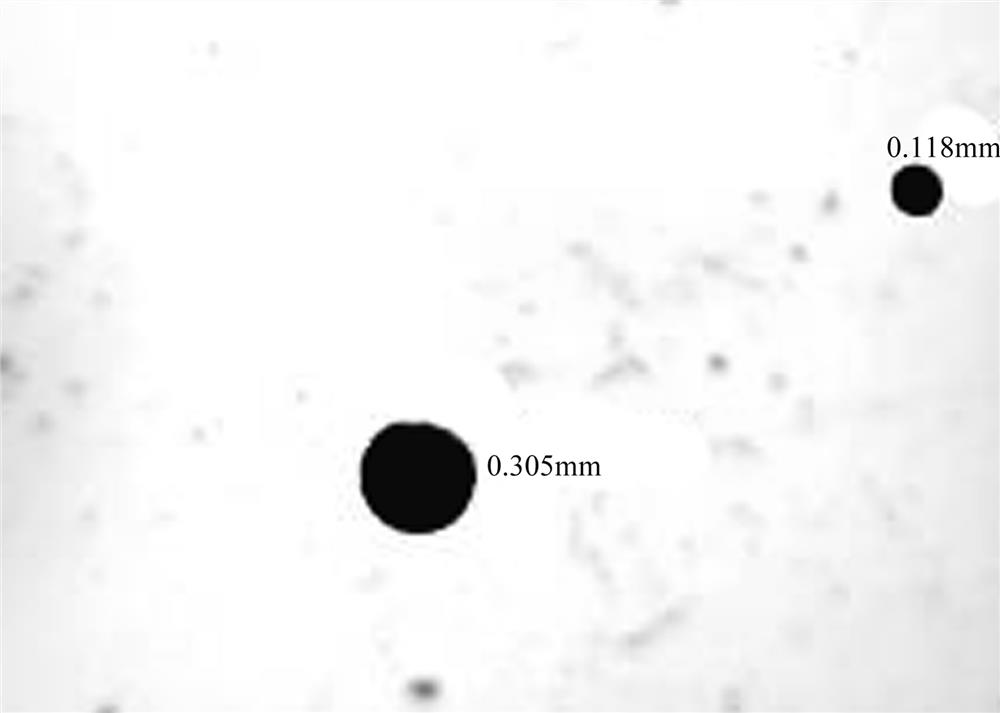

Image

Examples

Embodiment 1

[0052] A method for preparing ZrO2 microspheres by direct titration molding technology (gel casting process), mainly includes the following steps:

[0053] Step 1. Take 800g of ZrO2 ceramic powder with an average particle size of 0.1 μm, weigh 2.5% of the powder’s mass of acrylamide, 0.29% of the powder’s mass of N-N’methylenebisacrylamide, and Ammonium polycarboxylate with a mass of 1.0% and water accounting for 18% of the mass of the powder were stirred for 10 minutes to prepare a water solvent, and the ZrO2 ceramic powder and water solvent were added to a 20L planetary ball mill tank, wherein the spherical tank was a polyurethane tank, and the ball mill The medium is a ZrO2 ball with a diameter of 3 mm, and the ratio of material to ball (mass ratio) is 2:1. The rotational speed of the ball mill was set at 180r / min. After 7 hours of ball milling, the fluidity of the slurry was good. The measured viscosity was 82mPa·s (room temperature, rotational speed 20s-1), and the solid ...

Embodiment 2

[0058] A method for preparing ZrO2 microspheres by direct titration molding technology (normal temperature curing process), mainly comprising the following steps:

[0059] Step 1, get the ZrO2 powder 800g that average particle size is 0.1 μm, take by weighing the ammonium polycarboxylate dispersant that accounts for 1.0% of powder mass and the water that accounts for 20% of powder mass, make water solvent after stirring 10min; ZrO2 powder and water solvent are added to a 20L planetary ball mill tank, wherein the spherical tank is a polyurethane tank, the ball milling medium is a ZrO2 ball with a diameter of 3mm, and the material-to-ball ratio (mass ratio) is 2:1. The rotational speed of the ball mill was set at 180r / min. After 7 hours of ball milling, the fluidity of the slurry was good. The measured viscosity was 66mPa·s (room temperature, rotational speed 20s-1), and the solid content was 80%. Add Isobam, a normal temperature curing agent accounting for 1% of the mass of the...

Embodiment 3

[0064] A method for preparing Gd2O2S microspheres by direct titration molding technology (gel casting process), mainly includes the following steps:

[0065] Step 1: Take 800 g of Gd2O2S powder with an average particle size of 0.05 μm, weigh 2.55% of the mass of the powder, acrylamide, 0.31% of N-N'methylenebisacrylamide, 1.2% of ammonium polycarboxylate and Water, which accounts for 25% of the mass of the powder, is stirred for 10 minutes to obtain a water solvent; Gd2O2S powder and water solvent are added to a 20L planetary ball mill tank, wherein the spherical tank is a polyurethane tank, and the ball mill medium is a ZrO2 ball with a diameter of 3mm. (Mass ratio) is 2:1. The rotational speed of the ball mill is set at 180r / min. After 7 hours of ball milling, the fluidity of the slurry is good. The measured viscosity value is 110mPa•s (room temperature, rotational speed 20s-1), and the solid content is 80%. Add 0.47‰ of ammonium persulfate and 0.18‰ of tetramethylethylened...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com