Preparation method of cobalt-doped molybdenum disulfide with yolk-eggshell structure

An eggshell and egg yolk technology, which is applied in the preparation field of cobalt-doped molybdenum disulfide nanomaterials, can solve the problems of long preparation time, difficult removal of template agents, low product purity, etc., and achieves simple reaction steps, reduced introduction of impurities, Simple effect of product separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

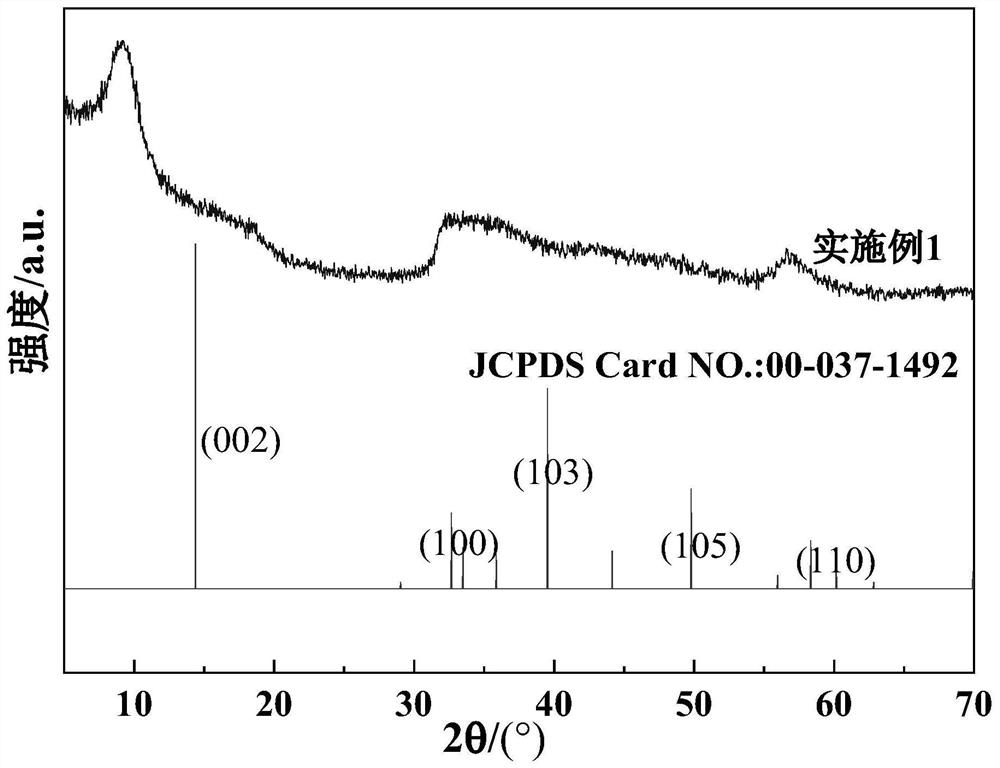

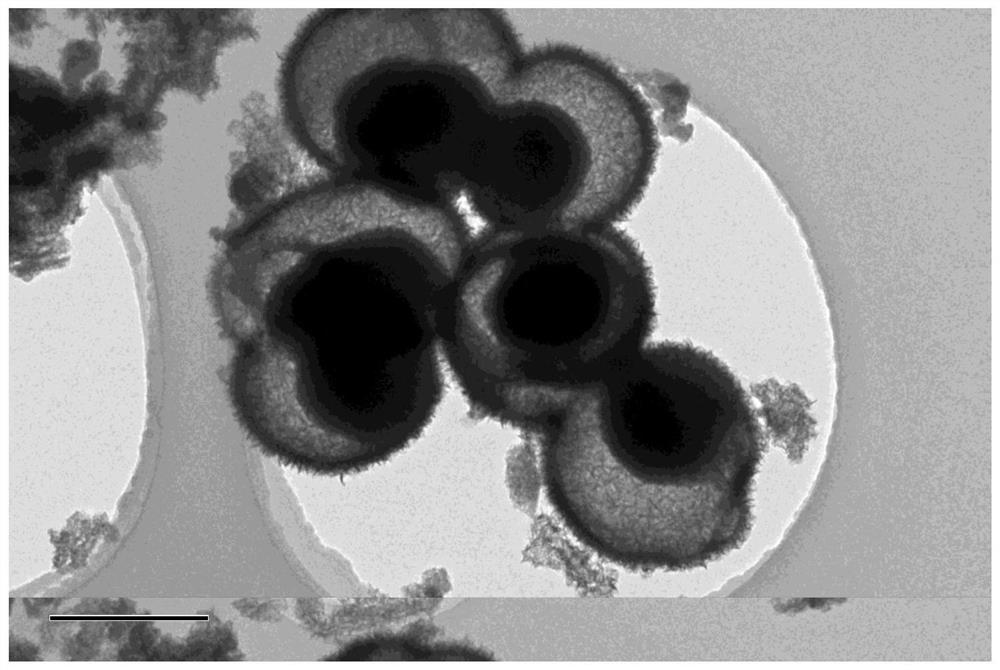

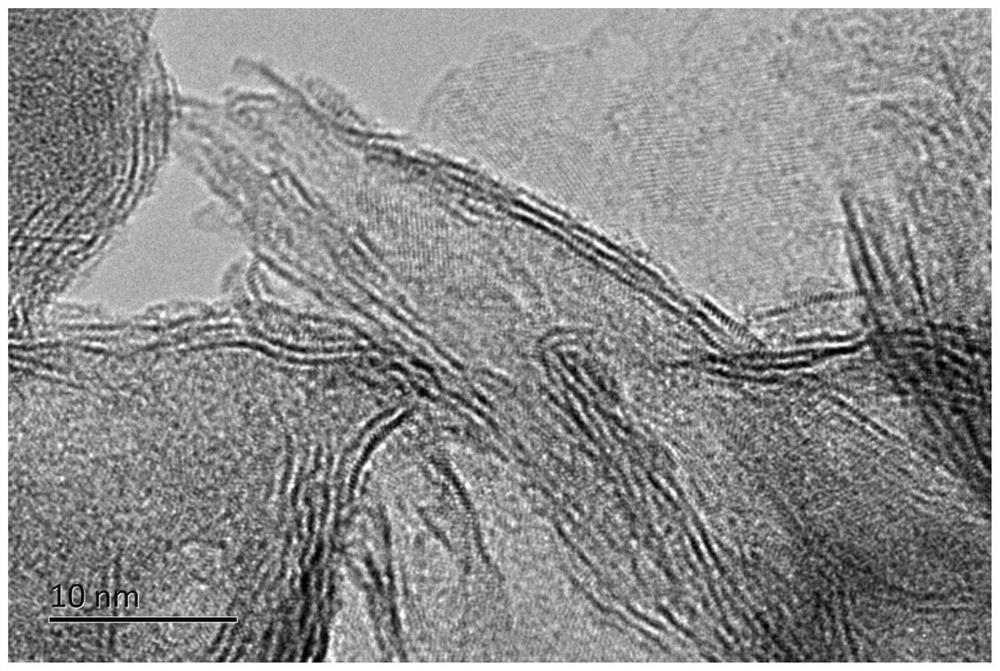

[0020] Weigh 2mmol molybdenum isooctanoate, 0.2mmol cobalt isooctanoate and 8.8mmol L-cysteine in a 100ml beaker, then add 25ml ethanol and 25ml deionized water to the beaker, and stir at 500rpm for 30min. The resulting suspension was transferred to a 100ml high-pressure reactor, and kept at 200°C for 16 hours. After natural cooling, suction filtration, the precipitate was washed with deionized water and absolute ethanol, and then vacuum-dried at 70°C for 12 hours to obtain a black powder. ICP data indicate that the resulting Co / MoS 2 The cobalt-molybdenum ratio in the medium is close to the feed ratio of the cobalt source and the molybdenum source (see Table 1), which shows that the cobalt source and the molybdenum source have been fully utilized. XRD characterization shows only 2H-MoS in the obtained black powder 2 The characteristic peaks indicate that cobalt species are uniformly dispersed in molybdenum disulfide or exist in an amorphous state. At the same time, the d...

Embodiment 2

[0022] Weigh 2mmol of molybdenum acetylacetonate, 0.2mmol of cobalt acetylacetonate and 8.8mmol of L-cysteine in a 100ml beaker in sequence, then add 50ml of ethanol into the beaker, and stir at 500rpm for 30min. The resulting solution was transferred to a 100ml high-pressure reactor, kept at 200°C for 16 hours, cooled naturally, filtered with suction, the precipitate was washed with deionized water and absolute ethanol, and then vacuum-dried at 70°C for 12 hours to obtain a black powder. ICP data indicate that the resulting Co / MoS 2 The cobalt-molybdenum ratio in the medium is close to the feed ratio of the cobalt source and the molybdenum source (see Table 1), which shows that the cobalt source and the molybdenum source have been fully utilized. XRD characterization shows only 2H-MoS in the obtained black powder 2 The characteristic peaks indicate that cobalt species are uniformly dispersed in molybdenum disulfide or exist in an amorphous state. At the same time, the dif...

Embodiment 3

[0024] Weigh 2mmol molybdenum isooctanoate, 0.2mmol cobalt isooctanoate and 8.8mmol thiourea in a 100ml beaker in turn, then add 25ml ethanol and 25ml deionized water to the beaker, and stir at 500rpm for 30min. The resulting suspension was transferred to a 100ml high-pressure reactor, and kept at 200°C for 16 hours. After natural cooling, suction filtration, the precipitate was washed with deionized water and absolute ethanol, and then vacuum-dried at 70°C for 12 hours to obtain a black powder. ICP data indicate that the resulting Co / MoS 2 The cobalt-molybdenum ratio in the medium is close to the feed ratio of the cobalt source and the molybdenum source (see Table 1), which shows that the cobalt source and the molybdenum source have been fully utilized. XRD characterization shows only 2H-MoS in the obtained black powder 2 The characteristic peaks indicate that cobalt species are uniformly dispersed in molybdenum disulfide or exist in an amorphous state. At the same time, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com