Method for producing copper chloride by using waste acidic etching liquid

A technology of acid etching solution and copper chloride, which is applied in the direction of copper chloride and copper halide, can solve the problems of high solid waste treatment cost, danger and consumption of waste acid etching solution, reduce solid waste treatment cost, increase copper Effect of ion concentration and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

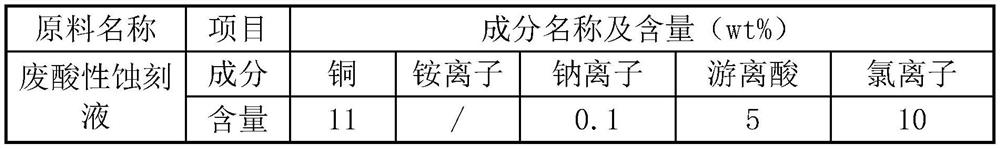

[0055]A method utilizing waste acid etching solution to produce copper chloride comprises the steps:

[0056] (1) Deacidification and purification

[0057] ① Add 10kg of waste circuit board copper powder to 100Kg of waste acid etching solution produced during the etching process of printed circuit boards, and stir for 1 hour at a stirring rate of 60 rpm;

[0058] ② Then add 5Kg of hydrogen peroxide, and continue to stir and react at a stirring rate of 60 rpm for 1 hour to obtain a reaction solution, the pH of which is 1-2;

[0059] ③ Continue to stir at a stirring rate of 60 rpm, add 30% sodium hydroxide to adjust the pH of the reaction solution to 3.5;

[0060] ④Continue to stir at a stirring rate of 60 rpm, then slowly add 1.5Kg of 0.2% polyacrylamide flocculant, and react for 0.3h; obtain a reaction mixture containing copper chloride;

[0061] (2) Solid-liquid separation

[0062] The reaction mixture obtained in step (1) is subjected to solid-liquid separation, and a box...

Embodiment 2

[0071] A method utilizing waste acid etching solution to produce copper chloride comprises the steps:

[0072] (1) Deacidification and purification

[0073] ① Add 15kg of waste circuit board copper powder to 100Kg of waste acid etching solution produced during the etching process of printed circuit boards, and stir for 2 hours at a stirring rate of 65 rpm;

[0074] ② Then add 8Kg of hydrogen peroxide, and continue to stir and react at a stirring rate of 65 rpm / min for 1 hour to obtain a reaction solution, the pH of which is 1-2;

[0075] ③Continue to stir at a stirring rate of 65 rpm, and add 30% sodium hydroxide to adjust the pH of the reaction solution to 3.8;

[0076] ④Continue to stir at a stirring rate of 65 rpm, then slowly add 1.2Kg of 0.5% flocculant, and react for 0.3h; obtain a reaction mixture;

[0077] (2) Solid-liquid separation

[0078] The reaction mixture obtained in step (1) is subjected to solid-liquid separation, and the solid-liquid separation adopts a b...

Embodiment 3

[0087] A method utilizing waste acid etching solution to produce copper chloride comprises the steps:

[0088] (1) Deacidification and purification

[0089] ① Add 8 kg of waste circuit board copper powder to 100 kg of waste acid etching solution produced during the etching process of printed circuit boards, and stir for 3 hours at a stirring rate of 55 rpm;

[0090] ②Then add hydrogen peroxide in an amount of 6Kg, and continue to stir and react at a stirring rate of 55 rpm for 1 hour to obtain a reaction solution, the pH of which is 1-2;

[0091] ③Continue to stir at a stirring rate of 55 rpm, and add 30% sodium hydroxide to adjust the pH of the reaction solution to 3.6;

[0092] ④Continue to stir at a stirring rate of 55 rpm, then slowly add 1.1Kg of 0.6% flocculant, and react for 0.3h; obtain a reaction mixture containing copper chloride;

[0093] (2) Solid-liquid separation

[0094] The reaction mixture that step (1) obtains is carried out solid-liquid separation, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com