Method and system for preparing silica aerogel

A silica and aerogel technology, applied in silica, silica and other directions, can solve the problems affecting the mass transfer, heat transfer and separation efficiency of rectification towers, equipment blockage, production uncertainty, etc., and reduce construction costs. cost, reduce the cost of raw materials, and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a system for preparing silica airgel, including:

[0047]The slurry hydrolysis tank is used to mix the slurry in polysilicon production with water, and the silicon-containing substance in the slurry undergoes a hydrolysis reaction to form silica sol to obtain a solid-liquid mixture;

[0048] The suction filtration device is connected with the slurry hydrolysis tank, and the suction filtration device is used to separate the solid-liquid mixture from the solid-liquid mixture to obtain a solid mixture and a liquid mixture, wherein the liquid mixture includes silica sol;

[0049] The neutralization tank is connected with the suction filtration device, and the neutralization tank is used to adjust the pH value of the liquid mixture to be alkaline with an alkaline solution for gelation treatment, and the silica sol in the liquid mixture generates silica gel; the neutralization tank also It is used to replace the silicone gel with solvent to replace th...

Embodiment 2

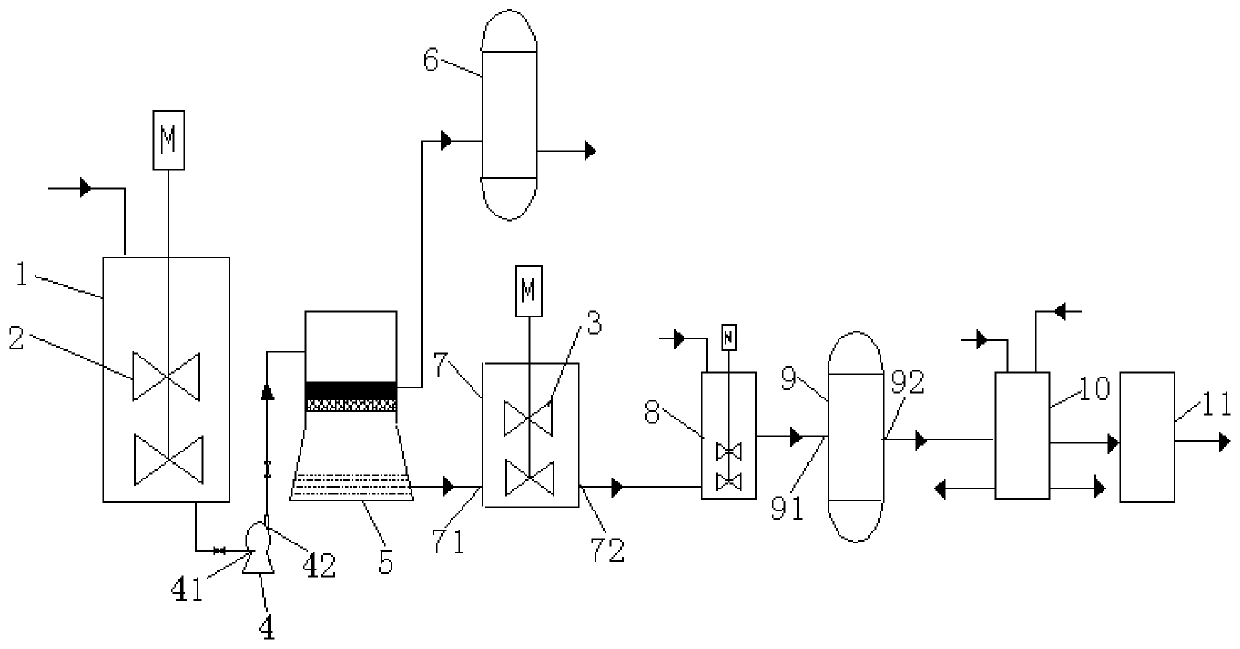

[0055] Such as figure 1 As shown, the present embodiment provides a system for preparing silica airgel, comprising:

[0056] The slurry hydrolysis tank 1 is used to mix the slurry in polysilicon production with water, and the silicon-containing substances in the slurry undergo hydrolysis reaction to form silica sol to obtain a solid-liquid mixture. Specifically, the first agitator 2 is installed in the slurry hydrolysis tank 1 in this embodiment, and the motor power of the first agitator 2 is adjusted according to the processing capacity of the slurry to ensure that the hydrolysis reaction is complete. The top of the slurry hydrolysis tank 1 is provided with a safety valve, which is connected to the leaching tower. The safety valve is used to prevent the rapid rise of the pressure in the slurry hydrolysis tank 1 and cause a safety accident.

[0057] The slurry waste liquid discharged from the polycrystalline silicon cold hydrogenation process containing silicon powder, cataly...

Embodiment 3

[0082] This embodiment provides a method for preparing silica airgel using the system in Embodiment 2, comprising the following steps:

[0083] 1) Mix the slurry in polysilicon production with water, and the silicon-containing substance in the slurry undergoes a hydrolysis reaction to form silica sol to obtain a solid-liquid mixture.

[0084] 2) Separating the solid-liquid mixture into a solid-liquid mixture to obtain a solid mixture and a liquid mixture respectively, wherein the liquid mixture includes silica sol.

[0085] 3) Take out the solid mixture for nitrogen protection, and carry out cold hydrogenation reaction with hydrogen and silicon tetrachloride.

[0086] 4) mixing the liquid mixture with a complexing agent, and removing the metal ions in the liquid mixture that can undergo complexation reaction to form precipitates through a complexation reaction to obtain a liquid mixture from which metal ions have been removed. Among them, the complexing agent includes F - and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com