Corrugated paperboard cutting device

A cutting device and a technology for corrugated cardboard, applied in the field of corrugated cardboard, can solve the problems of changes in the shape and protective ability of the corrugated paper cutting opening, inconvenient for workers to clean work, unfavorable protective work, etc., so as to improve cutting efficiency, ensure protective performance, and avoid deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

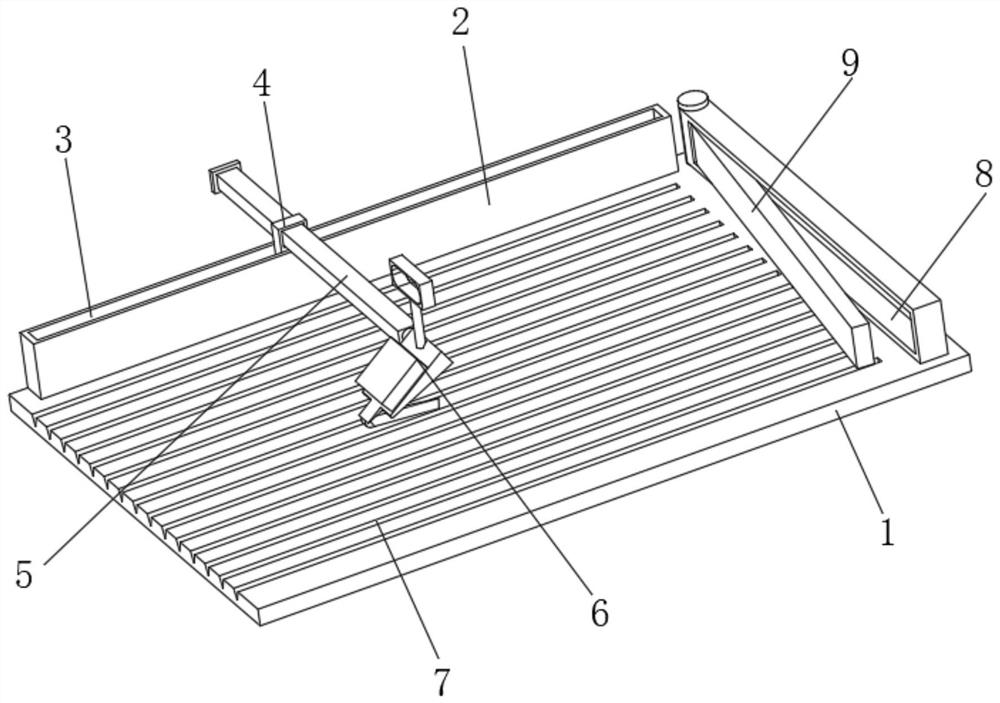

[0032] Such as figure 1 As shown, the present invention provides a technical solution: a corrugated cardboard cutting device, including a support pad 1, the back side of the top of the support pad 1 is fixedly connected with a limiting straight plate 2, and the top of the limiting straight plate 2 is provided with a limit track 3. The inside of the bit track 3 is slidably connected with an adjustment block 4, and the inside of the adjustment block 4 runs through and is slidably connected with a support insert rod 5. The end of the support insert rod 5 located at the front of the adjustment block 4 is rotatably connected with a cutting mechanism 6, and the support pad The surface of the top of the board 1 is uniformly and equidistantly provided with limiting grooves 7, the bottom of the cutting mechanism 6 is set correspondingly to the limiting grooves 7, the right side of the top of the supporting pad 1 is fixedly connected with a right-angled support plate 8, and the limiting ...

Embodiment 2

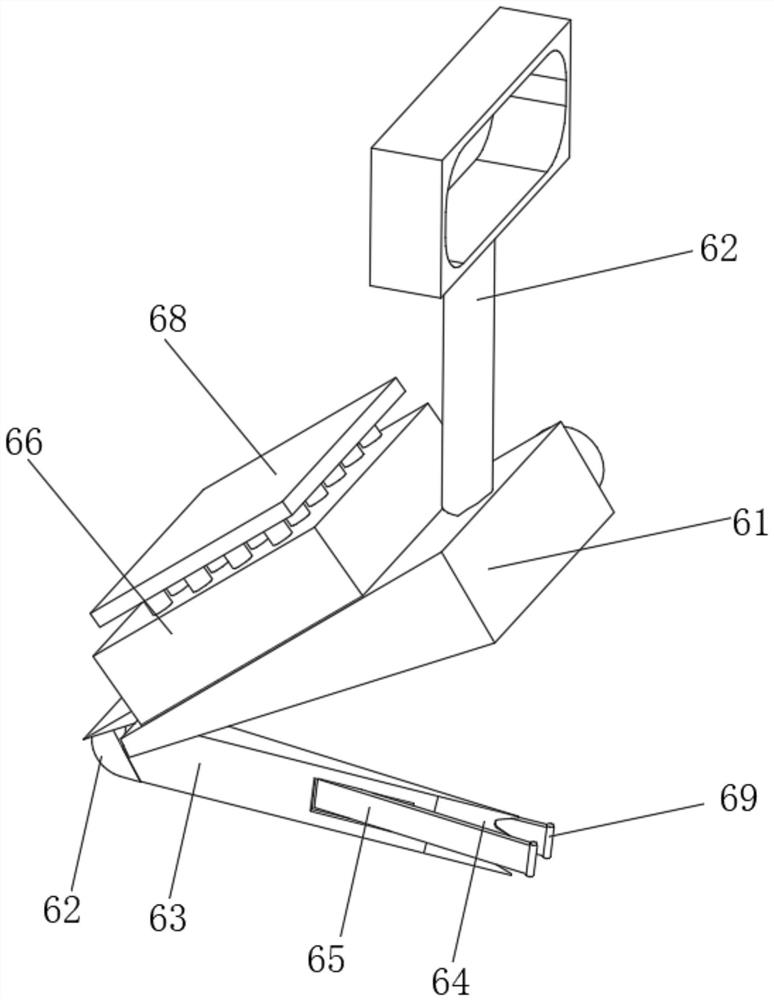

[0034] Such as Figure 2-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a corrugated cardboard cutting device, the cutting mechanism 6 includes an adjustment slant plate 61, and the position on the back of the adjustment slant plate 61 and near the upper side and the support insertion rod 5 Rotation connection, the top of the adjustment slant plate 61 is fixedly connected with a handle bar 62, the bottom end of the adjustment slant plate 61 is fixedly connected with a protective arc block 62 near the left side, and the bottom end of the adjustment slant plate 61 is located at the bottom of the protective arc block 62. The right side is fixedly connected with an extension guide rod 63 .

[0035] A blade assembly 64 is fixedly connected to the right end surface of the extension guide rod 63 , and a guide insertion rod 65 is rotatably connected to the front and rear sides of the extension guide rod 63 and near the right side. Reali...

Embodiment 3

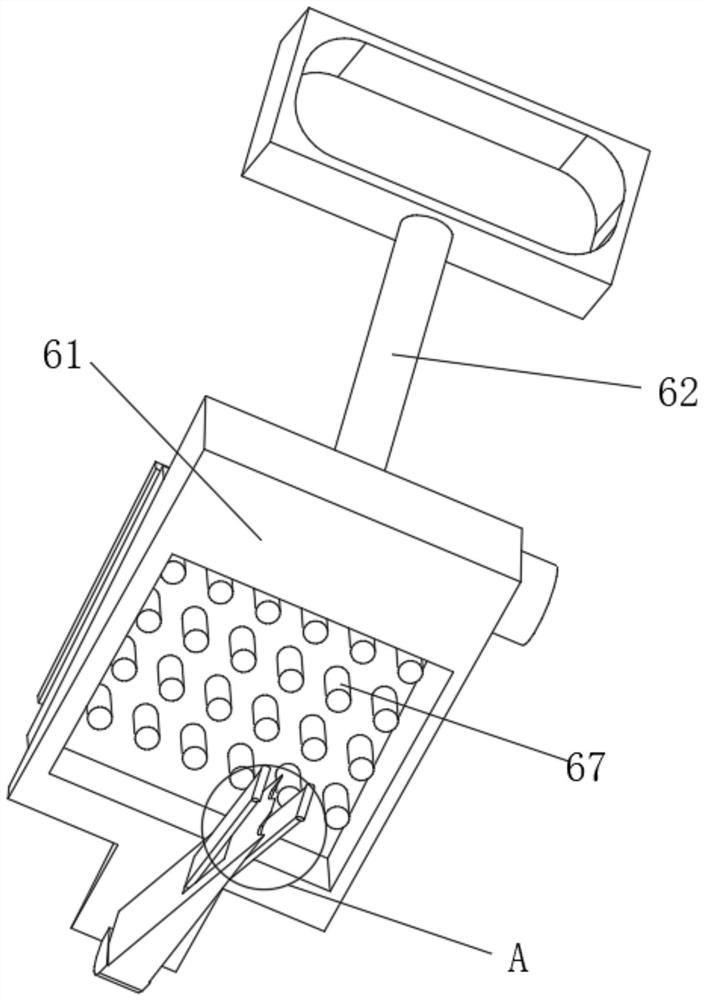

[0040] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a corrugated cardboard cutting device, the cleaning assembly 67 includes a support insert 671, and the support insert 671 is located at one end above the storage slot 66 It is fixedly connected with the processing pull plate 68 , and one end of the support insert 671 located inside the storage groove 66 is evenly and fixedly connected with a cleaning brush rod 672 .

[0041] The outer surface of the cleaning brush rod 672 is uniformly and fixedly connected with a scraper cone 673 , and the outer surface of the scraper cone 673 is evenly provided with an adsorption groove 674 . Increase the dust absorption capacity and improve the ability to clean the adsorbed dust.

[0042] Working principle: Attach the right-angled side of the corrugated cardboard to the surface of the limiting straight board 2, adjust the angle of the bevel adjustment plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com