Efficient preparation method of diamond/metal matrix composite material

A composite material and metal-based technology, applied in the field of diamond/metal-based composite material preparation, can solve the problems of complexity, diamond graphitization process, large energy loss, etc., to reduce energy loss, control product quality and stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

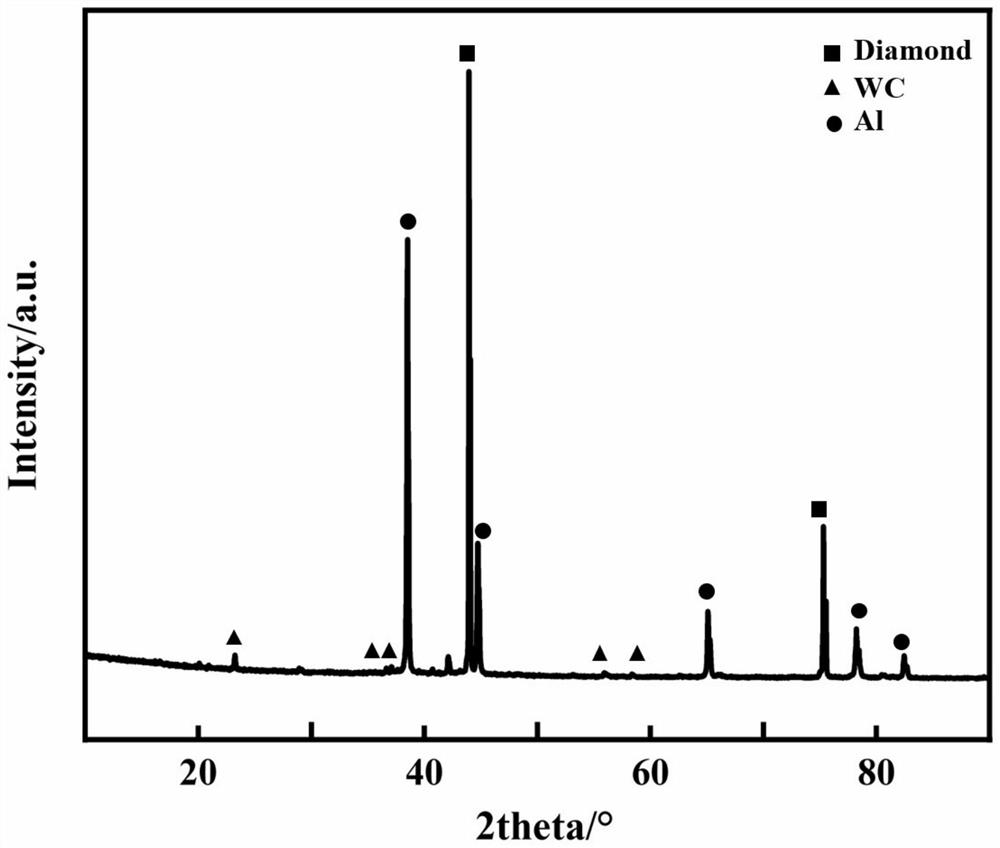

[0034] Specific implementation mode 1: The efficient preparation method of diamond / metal matrix composite material in this implementation mode is carried out according to the following steps:

[0035] 1. Weighing and filling:

[0036] Weigh the diamond powder with metal coating, fill the diamond powder in the cavity of the graphite mold, and vibrate the diamond powder with an ultrasonic vibrating table;

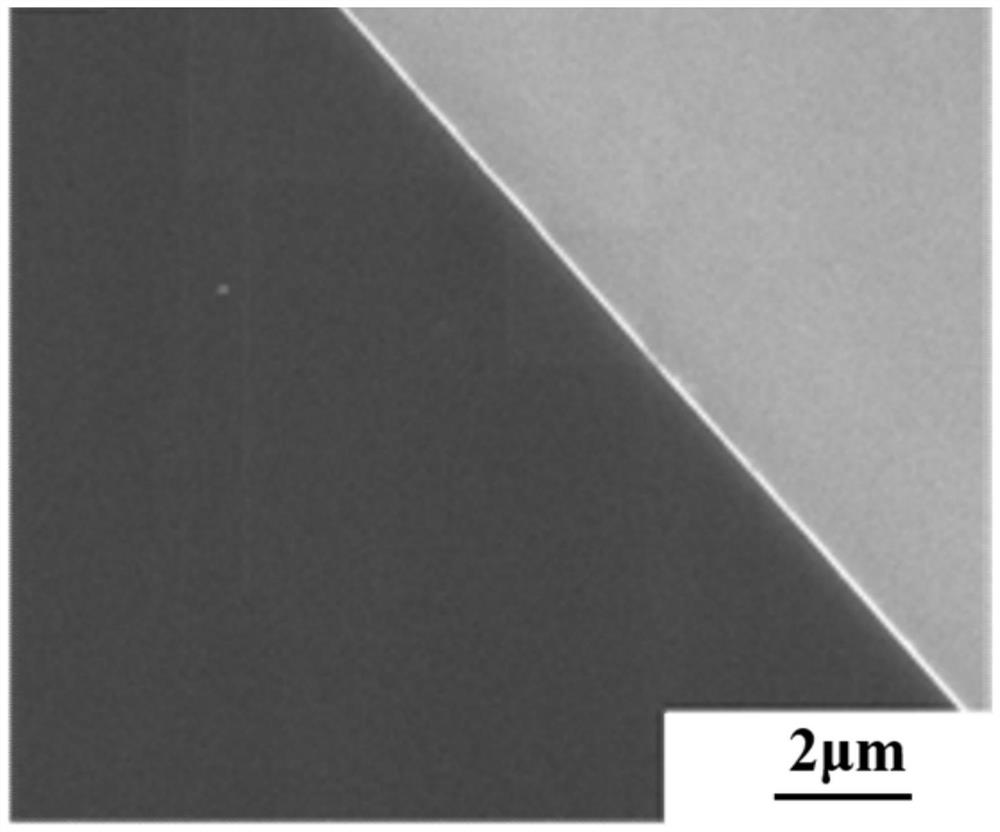

[0037] The metal coating is one of W, Ti, Cr, Mo;

[0038] 2. Low temperature diffusion treatment:

[0039] Put the forming mold with diamond powder into the vacuum pressure impregnation furnace and heat it to the low-temperature diffusion temperature for low-temperature diffusion treatment;

[0040] When the coating metal is W, the low-temperature diffusion temperature is 700-750°C, and the holding time is 6-12h;

[0041] When the coating metal is Ti, the low-temperature diffusion temperature is 650-700°C, and the holding time is 5-10h;

[0042] When the coating metal is...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment differs from Embodiment 1 in that: the thickness of the metal coating in step 1 is 20-500 nm.

specific Embodiment approach 3

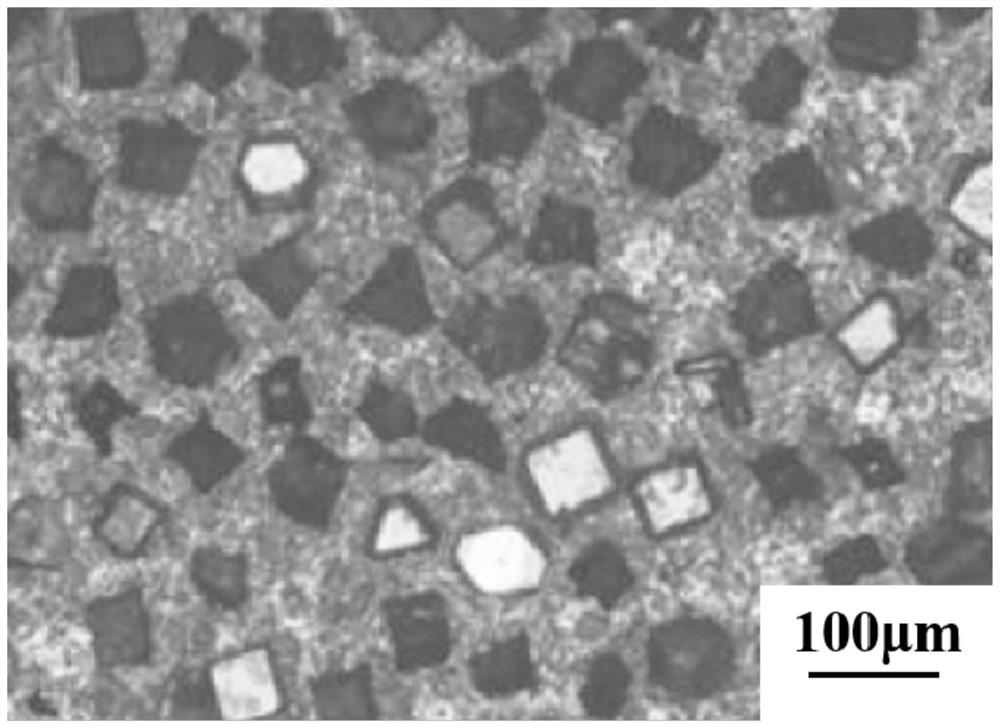

[0057] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that: the particle size of the diamond powder in step 1 is 30-120 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com