Preparation method of pre-lithiated MXenes material and application of pre-lithiated MXenes material in battery electrode material

A pre-lithiation and magnesium battery technology, applied in the field of new energy storage, can solve the problems affecting the first coulombic efficiency and storage capacity of electrode materials, achieve the effect of improving the rate and cycle performance, simple process method, and making up for losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Prelithiated MXeneV 2 The preparation of C comprises the steps:

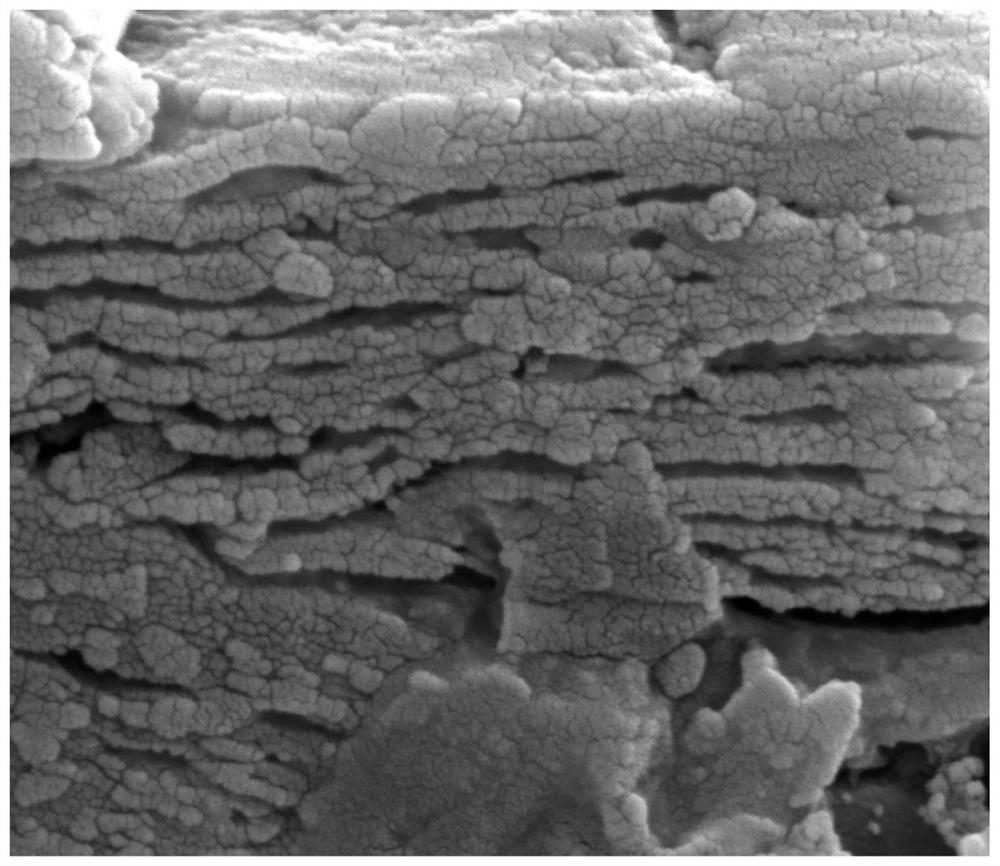

[0032] (1) The particle size is 500 mesh 1gV 2 The AlC powder is immersed in 20mL of a mixed solution of hydrochloric acid and sodium fluoride with a concentration of 6mol / L, stirred at 90°C for 72h, cooled to room temperature, then poured into a centrifuge tube, and centrifuged several times with deionized water until the The solution in the tube was neutral, and the upper layer solution was precipitated. The sample left at the bottom of the centrifuge tube was dried in a vacuum oven at 80°C for 12 hours to obtain the two-dimensional crystal compound MXeneV 2 C;

[0033] (2) Pre-lithiated MXeneV 2 Preparation of sheet C: glass sheet, lithium foil, two-dimensional crystal compound MXeneV 2 C. Steel sheets and glass sheets are placed in order from top to bottom; after placement, electrolyte LiPF is dripped from the side 6 , exert a certain pressure on the uppermost glass bottle, so that the lithium fo...

Embodiment 2

[0036] Prelithiated MXeneTi 3 C 2 The preparation comprises the following steps:

[0037] (1) 1gTi with a particle size of 500 mesh 3 AlC 2 The powder is immersed in 20mL of a mixed solution of hydrochloric acid and sodium fluoride with a concentration of 6mol / L, stirred at 60°C for 24h, cooled to room temperature, then poured into a centrifuge tube, and centrifuged several times with deionized water until the centrifuge tube The solution in the solution was neutral, and the upper layer solution was precipitated. The sample left at the bottom of the centrifuge tube was placed in a vacuum drying oven at 80°C for 12 hours to obtain a two-dimensional crystal compound MXeneTi 3 C 2 ;

[0038] (2) Pre-lithiated MXeneTi 3 C 2 Preparation of sheet: glass sheet, lithium foil, two-dimensional crystal compound MXeneTi 3 C 2 , steel sheet, and glass sheet are placed in order from top to bottom; after placement, the electrolyte LiPF is dripped from the side 6 , exert a certain p...

Embodiment 3

[0040] A kind of preparation of lithium ion battery: according to mass ratio be 8:1:1, take the pre-lithiated MXeneV prepared in embodiment 1 respectively 2 C. Mix acetylene black and binder, add N-methylpyrrolidone as a solvent, grind it into a slurry, and evenly coat 1mg / cm 2 Afterwards, vacuum drying at 80 °C for 12 h yielded pre-lithiated MXeneV 2 C electrode sheet; with lithium foil as negative electrode, LiPF 6 As the electrolyte, it was assembled into a button lithium electronic battery in a glove box.

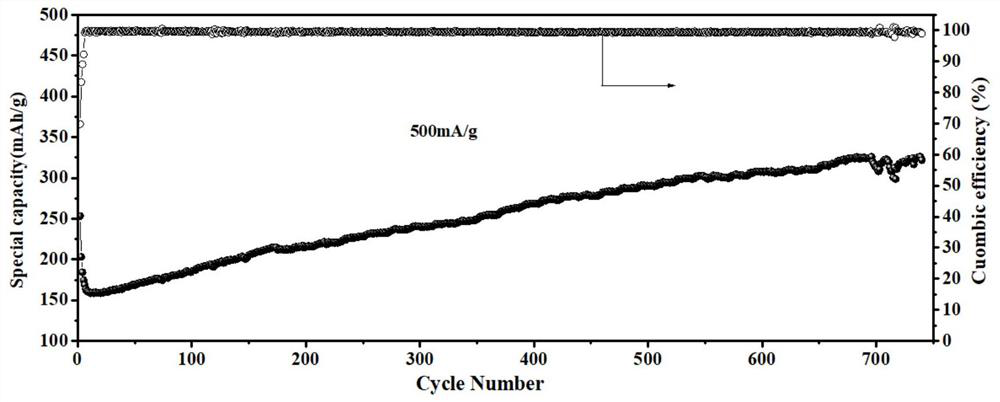

[0041] The lithium-ion battery assembled in this embodiment was tested at a current density of 50mA / g, and the cycle performance when the voltage range was 0.01-3.0V; the test results showed that the V 2 C, as an electrode material for ion batteries, its initial charge and discharge capacity is 656mAh / g, and its coulombic efficiency is 75%; compared to MXeneV without pre-lithiation treatment 2 C's first charge and discharge capacity, Coulombic efficiency and lithium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com