Melt spinning method of low-melting-point polyester FDY filaments

A melt-spinning, low-melting-point technology, applied in the field of polyester FDY filament processing, can solve the problems of polyester FDY filaments with insufficient hydrophilicity and unstable structure, so as to improve hydrophilicity, improve physical properties, and promote crystallization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

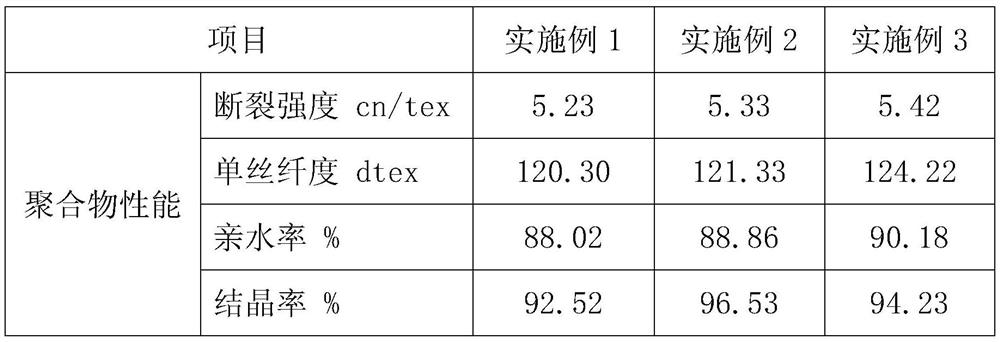

Embodiment 1

[0033] refer to figure 1 , a kind of melt-spinning method of low melting point polyester FDY filament, comprises the following steps:

[0034] S1: preparing slurry, adding a mixture of terephthalic acid and isophthalic acid and a mixture of succinic acid and glutaric acid into the reactor, and then mixing to prepare slurry;

[0035] S2: The first esterification, adding the prepared slurry and compounding additives to the esterification reactor for the first esterification reaction to obtain product A. The compounding additives in S2 are one or more of organotin and lead salts kind;

[0036] S3: Esterify again, add polyhydric alcohol to product A, carry out the second esterification reaction, obtain product B;

[0037] S4: Polycondensation reaction, adding the obtained product B into a polycondensation reactor for polycondensation reaction, and then obtaining a low melting point polyester melt;

[0038] S5: as-spun fibers, distributing the low-melting-point polyester melt to...

Embodiment 2

[0045] refer to figure 1 , a kind of melt-spinning method of low melting point polyester FDY filament, comprises the following steps:

[0046] S1: preparing slurry, adding a mixture of terephthalic acid and isophthalic acid and a mixture of succinic acid and glutaric acid into the reactor, and then mixing to prepare slurry;

[0047] S2: The first esterification, adding the prepared slurry and compounding additives to the esterification reactor for the first esterification reaction to obtain product A. The compounding additives in S2 are one or more of organotin and lead salts kind;

[0048] S3: Esterify again, add polyhydric alcohol to product A, carry out the second esterification reaction, obtain product B;

[0049] S4: Polycondensation reaction, adding the obtained product B into a polycondensation reactor for polycondensation reaction, and then obtaining a low melting point polyester melt;

[0050] S5: as-spun fibers, distributing the low-melting-point polyester melt to e...

Embodiment 3

[0057] refer to figure 1 , a kind of melt-spinning method of low melting point polyester FDY filament, comprises the following steps:

[0058] S1: preparing slurry, adding a mixture of terephthalic acid and isophthalic acid and a mixture of succinic acid and glutaric acid into the reactor, and then mixing to prepare slurry;

[0059] S2: The first esterification, adding the prepared slurry and compounding additives to the esterification reactor for the first esterification reaction to obtain product A. The compounding additives in S2 are one or more of organotin and lead salts kind;

[0060] S3: Esterify again, add polyhydric alcohol to product A, carry out the second esterification reaction, obtain product B;

[0061] S4: Polycondensation reaction, adding the obtained product B into a polycondensation reactor for polycondensation reaction, and then obtaining a low melting point polyester melt;

[0062] S5: as-spun fibers, distributing the low-melting-point polyester melt to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com