Preparation method and device of whitewashing agent suitable for color card base printing material

A technology for printing materials and preparation devices, which is applied in the direction of chemical instruments and methods, reagents, adhesives, etc., can solve the problems that cannot meet the requirements for preparing high-end personalized bank cards and other cards, and the peeling strength of the whitening agent is not enough, so as to achieve peeling The effect of less strength attenuation, avoiding uneven thickness, and strong ink fixing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

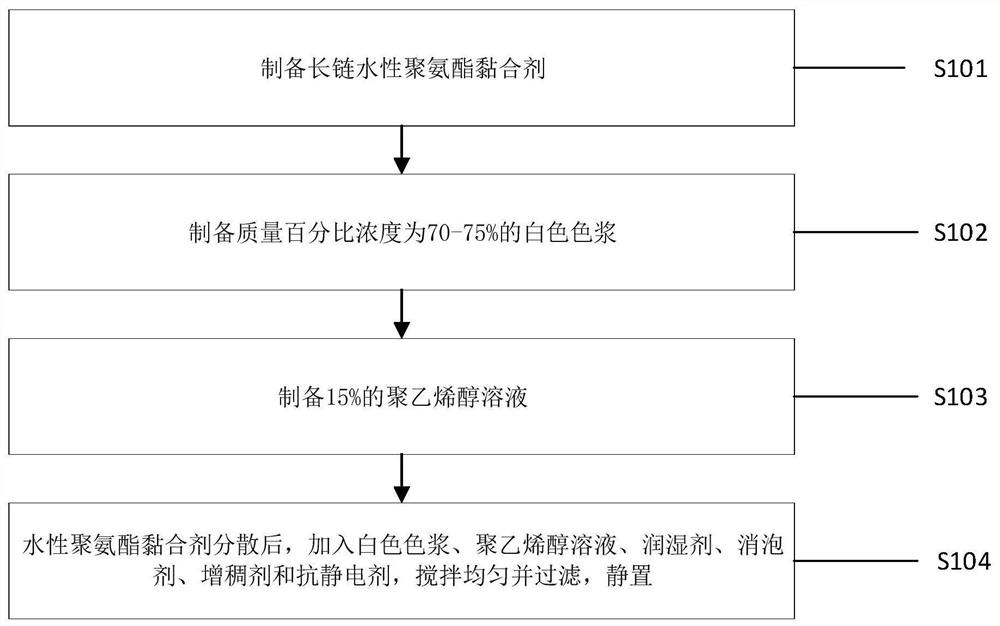

[0033] First, see Figure 1 to Figure 4 , the invention provides a kind of preparation method adapting to the whitening agent of color card base printing material, comprising:

[0034] S101 prepares long-chain waterborne polyurethane adhesive;

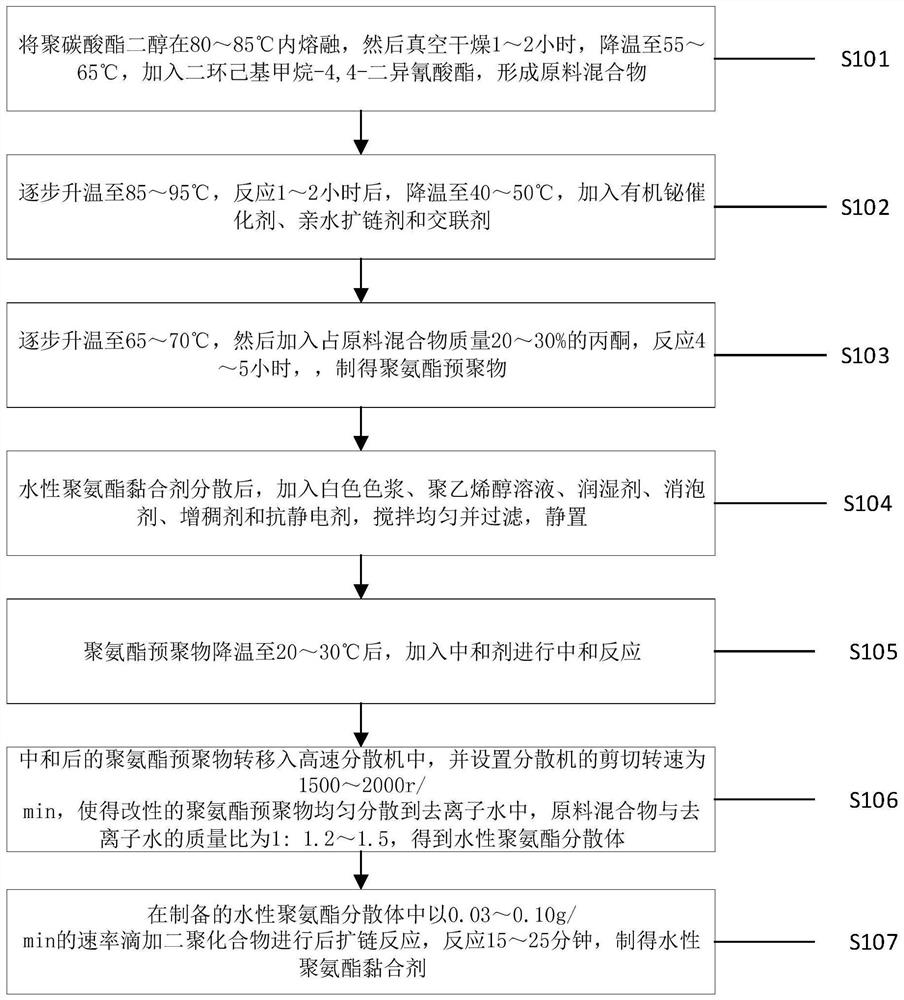

[0035] The specific steps are:

[0036] S201 Melt polycarbonate diol at 80-85°C, then vacuum-dry for 1-2 hours, cool down to 55-65°C, add dicyclohexylmethane-4,4-diisocyanate to form a raw material mixture;

[0037] S202 Gradually raise the temperature to 85-95°C, react for 1-2 hours, then cool down to 40-50°C, add organic bismuth catalyst, hydrophilic chain extender and cross-linking agent;

[0038] S203 is gradually heated up to 65-70°C, then adding acetone accounting for 20-30% of the mass of the raw material mixture, and reacting for 4-5 hours to obtain a polyurethane prepolymer;

[0039] After the S204 polyurethane prepolymer cools down to 20-30°C, add a neutralizing agent for neutralization reaction;

[0040]S205 The neutrali...

Embodiment 1

[0062] Add 15g of polycarbonate diol into a 500ml four-neck flask, raise the temperature to 80°C, then vacuum-dry for 1.0 hour, cool down to 55°C, add 50g of dicyclohexylmethane-4,4-diisocyanate, and then gradually raise the temperature to 85°C. After reacting for 1 hour, lower the temperature to 40°C, add 0.013g of bismuth-zinc composite catalyst, 5.20g of hydrophilic chain extender dimethylol butyric acid, 3.25g of crosslinking agent 1,4-cyclohexanediol and 1.95g of diethanolamine , and gradually raised the temperature to 65° C., then added 13.0 g of acetone, and continued the reaction for 4 hours. Cool down to 20°C, add 10.40g of triethylamine for neutralization, and continue the reaction for 20 minutes. After stirring 78.0g of ionized water for 15min, 1.625g of chain extender hydrazine hydrate was added dropwise at a rate of 0.03g / min for secondary chain extension, and continued for 15min to obtain 135.60g of water-based polyurethane adhesive for use.

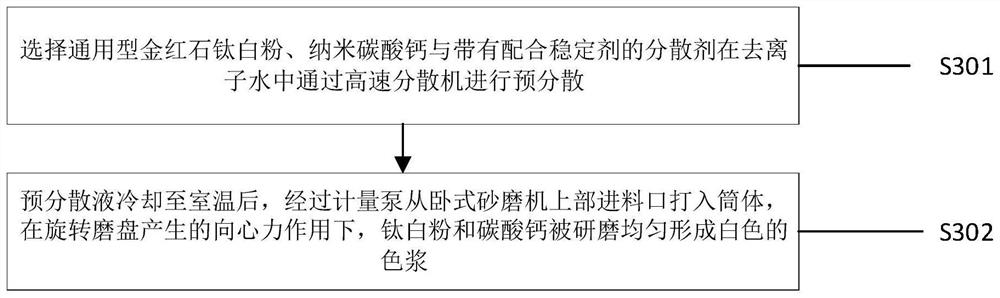

[0063] 200g of ge...

Embodiment 2

[0074] Add 25g of polycarbonate diol into a 500ml four-neck flask, raise the temperature to 85°C, then vacuum-dry for 2.0 hours, cool down to 65°C, add 50g of dicyclohexylmethane-4,4-diisocyanate, and then gradually raise the temperature to 95°C. After reacting for 2 hours, lower the temperature to 50°C, add 0.0225g of bismuth-zinc composite catalyst, 7.50g of hydrophilic chain extender dimethylol butyric acid, 7.5g of crosslinking agent 1,4-cyclohexanediol and 3.75g of diethanolamine , gradually warming up to 70° C., then adding 22.5 g of acetone, and continuing the reaction for 5 hours. Cool down to 30°C, add 22.5g of triethylamine for neutralization, and continue the reaction for 25 minutes. After stirring 112.5g of ionized water for 15min, 1.875g of chain extender hydrazine hydrate was added dropwise at a rate of 0.10g / min for secondary chain extension, and continued for 15min to obtain 189.50g of water-based polyurethane adhesive for later use.

[0075] 200g of general-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com