A kind of amidated graphene/nylon 6 nanocomposite material and preparation method thereof

A nanocomposite material and graphene technology, which is applied in the field of amidated graphene/nylon 6 nanocomposite material and its preparation, can solve the problem of low elongation at break and impact strength of composite materials, affecting the performance of composite materials, and the decrease of nylon molecular weight, etc. problems, to achieve good processability, reduce van der Waals force, and increase melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of amidated graphene / nylon 6 nanocomposite, comprising the following process steps:

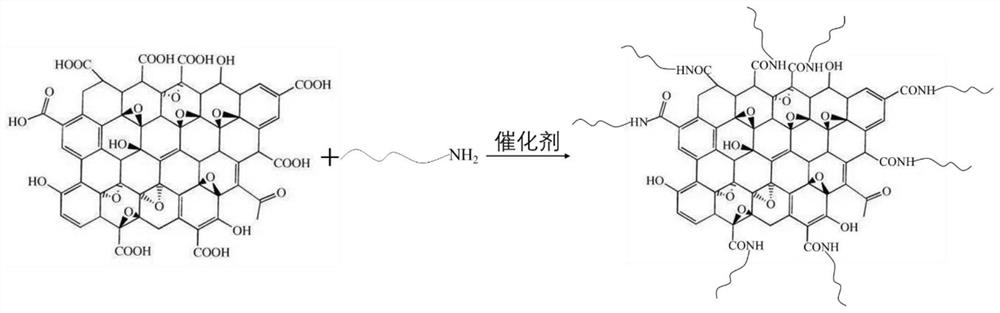

[0040] Step 1, disperse 100 parts of graphene oxide in deionized water to form a dispersion with a concentration of 0.5 mg / mL, add 5 parts of catalyst, the catalyst is 1-(3-dimethylaminopropyl)-3-ethyl The carbodiimide hydrochloride (EDC) and N-hydroxysuccinimide (NHS) molar ratio of MES buffer of 1:1 was stirred at room temperature for 30min to activate the carboxyl group;

[0041] Step 2, adding 5 parts of n-butylamine to the above graphene oxide dispersion liquid, stirring at room temperature for 12h to react, filtering, washing and then vacuum drying to obtain amidated graphene powder;

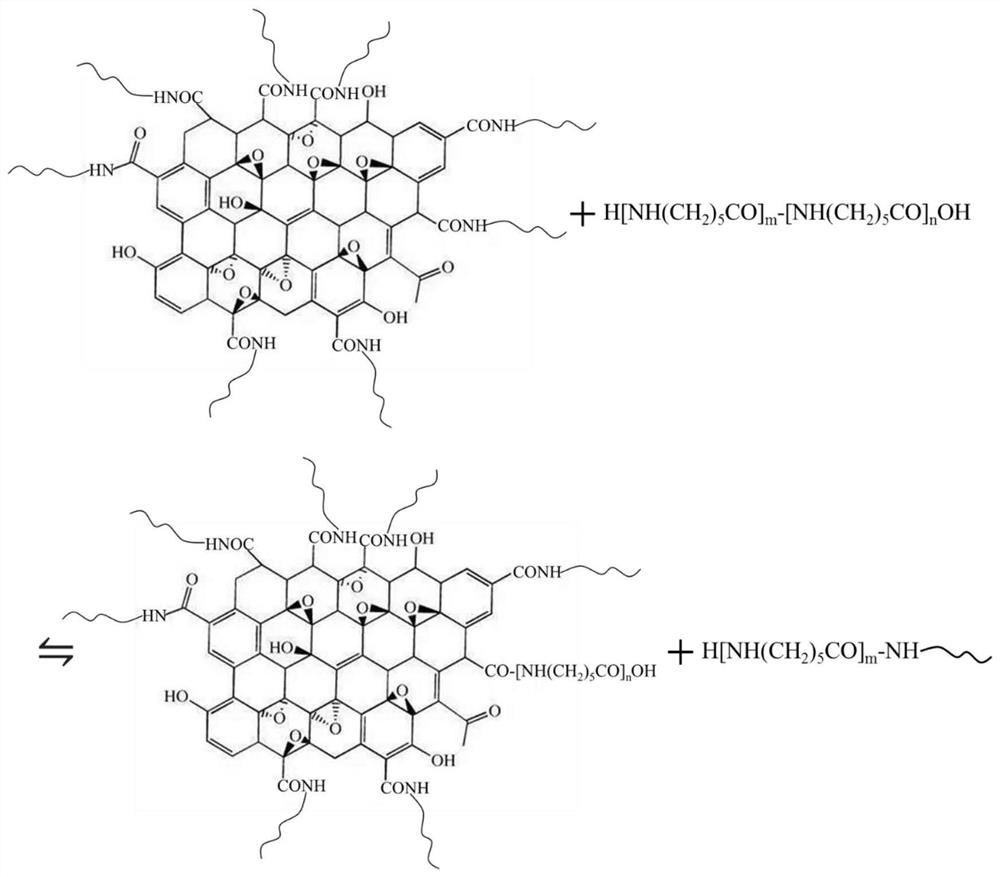

[0042] Step 3, adding 0.1 parts by mass of amidated graphene powder and 2 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and ultrasonically stirred for 30 min at 80° C. to form a dispersion;

[0043] Step 4: Under nitrogen protection, the above di...

Embodiment 2

[0050] A preparation method of amidated graphene / nylon 6 nanocomposite, comprising the following process steps:

[0051] Step 1, disperse 100 parts of graphene oxide in deionized water to form a dispersion with a concentration of 2mg / mL, add 5 parts of catalyst, the catalyst is 1-(3-dimethylaminopropyl)-3-ethyl carbon Diimine hydrochloride (EDC) and N-hydroxysuccinimide (NHS) in MES buffer with a molar ratio of 1:1 were stirred at room temperature for 50 min to activate the carboxyl group;

[0052] Step 2, adding 6 parts of n-butylamine to the above graphene oxide dispersion liquid, stirring at room temperature for 12h to react, filtering, washing and then vacuum drying to obtain amidated graphene powder;

[0053] Step 3, adding 0.3 parts by mass of amidated graphene powder and 4 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and ultrasonically stirred for 60 min at 80° C. to form a dispersion;

[0054] Step 4: Under the protection of nitrogen, t...

Embodiment 3

[0057] A preparation method of amidated graphene / nylon 6 nanocomposite, comprising the following process steps:

[0058] Step 1, disperse 100 parts of graphene oxide in deionized water to prepare a dispersion with a concentration of 1 mg / mL, add 5 parts of catalyst, the catalyst is 1-(3-dimethylaminopropyl)-3-ethylcarbon The MES buffer with diimine hydrochloride (EDC) and N-hydroxysuccinimide (NHS) molar ratio of 1.5:1 was stirred at room temperature for 40 min to activate the carboxyl group;

[0059] Step 2, adding 5 parts of n-hexylamine to the above graphene oxide dispersion liquid, stirring at room temperature for 15h to react, filtering, washing and then vacuum drying to obtain amidated graphene powder;

[0060] Step 3, adding 0.2 parts by mass of amidated graphene powder and 2 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and ultrasonically stirred for 40 min at 100° C. to form a dispersion;

[0061] Step 4: Under nitrogen protection, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com