Tyre inner lining glue with graphene/carbon black composite and preparation method of tyre inner lining glue

A technology of composite materials and inner liner adhesive, which is applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as poor interface interaction and difficulty in graphene dispersion, so as to increase production capacity, weaken van der Waals force, and accelerate stripping speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

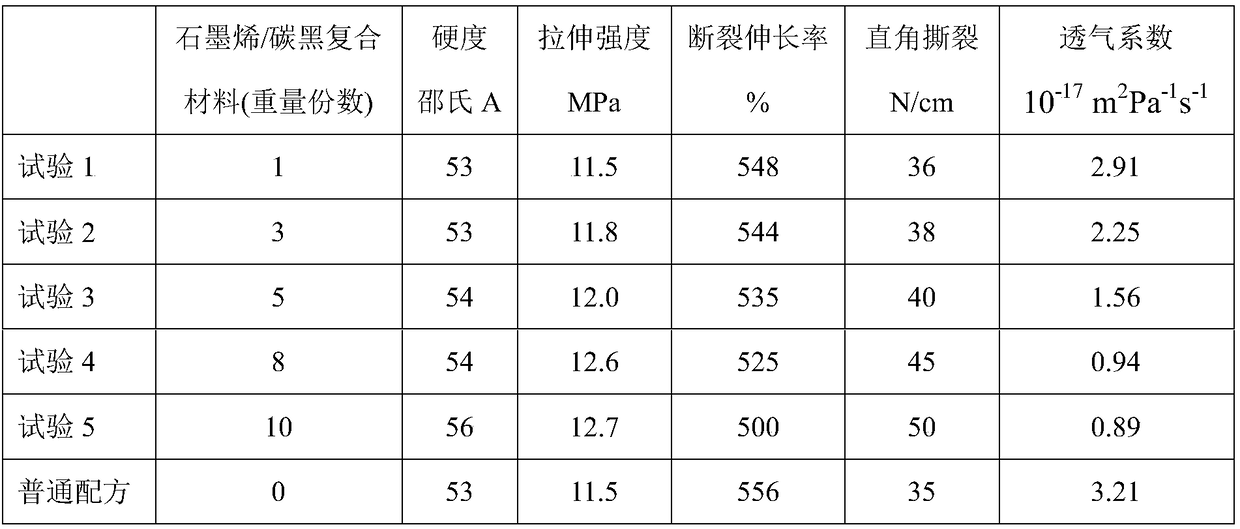

Examples

Embodiment 1

[0030] 1. Preparation of graphene / carbon black composites

[0031] (1) Add 100 parts of expanded graphite and 1 part of processing aid PVP-K30 to 500 parts of deionized water, stir in a disperser for 10 minutes at high speed, and after the dispersion is uniform, it is initially dissociated by a stripping device to make a graphite slurry;

[0032] (2) Add 100 parts of carbon black N-330 and 10 parts of dispersant PEG-4000 into 500 parts of deionized water, stir evenly, and ultrasonically stir for 30 minutes at a power of 1000W to prepare a uniformly dispersed carbon black dispersion;

[0033] (3) Mix the graphite slurry with the carbon black dispersion at a mass ratio of 1:1, stir evenly at a high speed, emulsify twice through an emulsifier, and then finely dissociate through a stripping device to make a graphene / carbon black composite slurry to make it well mixed;

[0034] (4) After the graphene / carbon black composite slurry is dried by spray drying equipment, the graphene / ca...

Embodiment 2

[0042] 1. Preparation of graphene / carbon black composites

[0043] (1) Add 200 parts of expanded graphite and 2 parts of processing aid N-vinyl formamide to 500 parts of deionized water, stir in a disperser for 10 minutes at high speed, and after the dispersion is uniform, the graphite slurry is initially dissociated by stripping equipment;

[0044] (2) Add 100 parts of carbon black N-330 and 10 parts of dispersant PEG-4000 into 500 parts of deionized water, stir evenly, and ultrasonically stir for 30 minutes at a power of 1000W to prepare a uniformly dispersed carbon black dispersion;

[0045] (3) Mix the graphite slurry with the carbon black dispersion mass ratio of 2:1, stir evenly at a high speed, emulsify twice through an emulsifier, and then finely dissociate through a stripping device to make a graphene / carbon black composite slurry to make it well mixed;

[0046] (4) After the graphene / carbon black composite slurry is dried by spray drying equipment, the graphene / carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com