Degradation method of algal polysaccharides

A seaweed polysaccharide and seaweed extraction technology, which is applied in the field of marine chemical engineering, can solve the problems of unstable molecular weight of finished products, environmental pollution, large molecular weight, etc., and achieves the effects of good application prospect, process safety and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Wash, after drying, the seaweed is ultrafinely pulverized, and 100 g is mixed with 400 ml 95 vol% ethanol solution, and then reflux 3 times in a micro-boiling state, a total of 5 h, then collect the extraction liquid to collect precipitation and dry, For the pre-treatment of seaweed ultrafine powder.

[0038] (2) Pre-treatment, the seaweed ultrafine powder is from 1 g: 50 mL ratio, using hot water method to extract the seaweed polysaccharide, extracting the extraction conditions at 100 ° C for 4 h, extracting liquid after centrifugation, evaporating the vacuum rotary evaporator Concentrated, then 95 vol% ethanol was slowly added to give the final concentration of 80% by weight, and the oscillation was mixed, and then placed at 4 ° C for 12 h, the next day, the resulting precipitate was washed with 95 vol% ethanol, after 25 ° C under conditions. Place, after ethanol, add the right amount of pure water recolition, and finally the vacuum rotary evaporator is concentrated and...

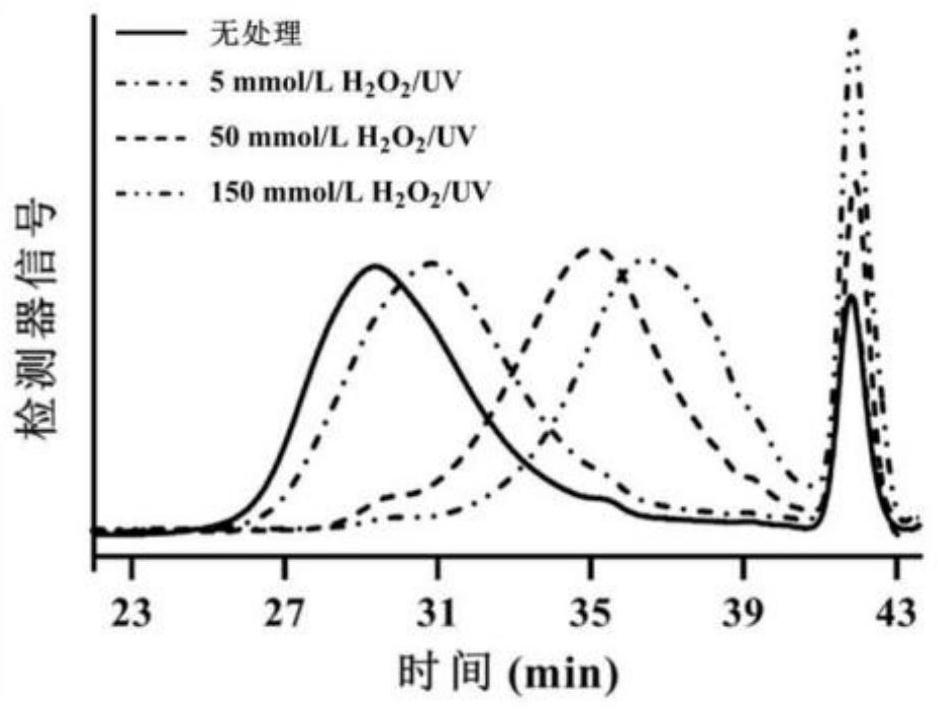

Embodiment 2

[0041] In addition to Hes with a concentration of 5 mmol / L 2 O 2 The aqueous solution is replaced with a concentration of 50 mmol / L 2 O 2 Outside the aqueous solution, the remaining and Example 1 were identical.

Embodiment 3

[0043] In addition to Hes with a concentration of 5 mmol / L 2 O 2 The aqueous solution is replaced with a concentration of 150 mmol / L 2 O 2 Outside the aqueous solution, the remaining and Example 1 were identical.

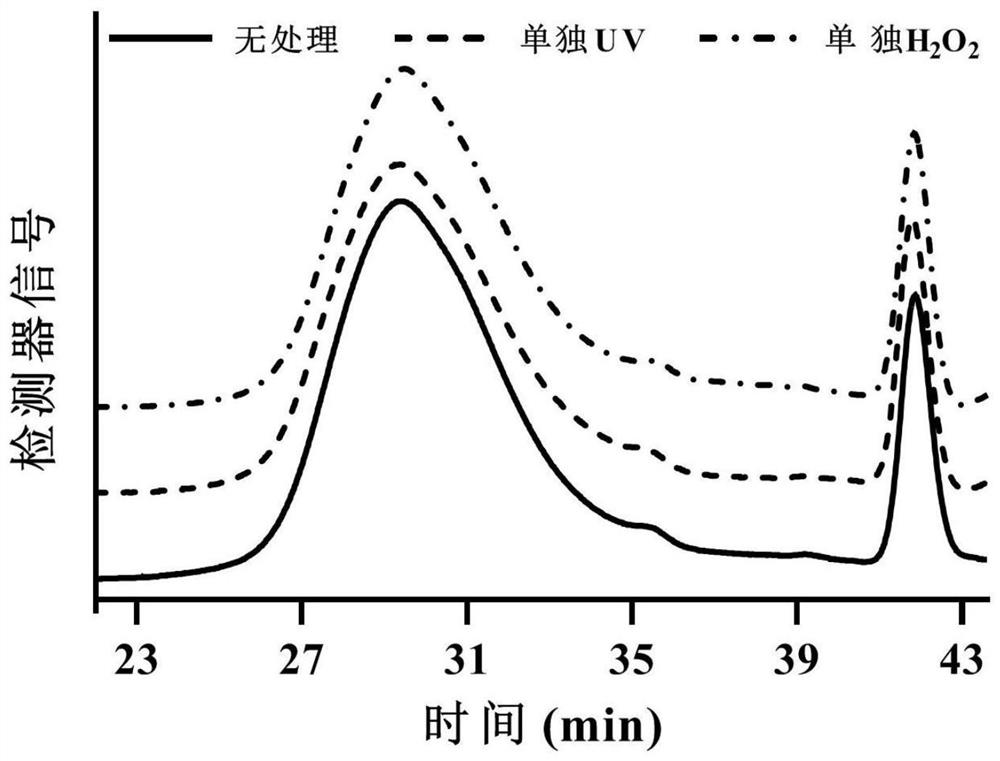

[0044] Molecular weight determination of the degradation product of Examples 1 to Example 3

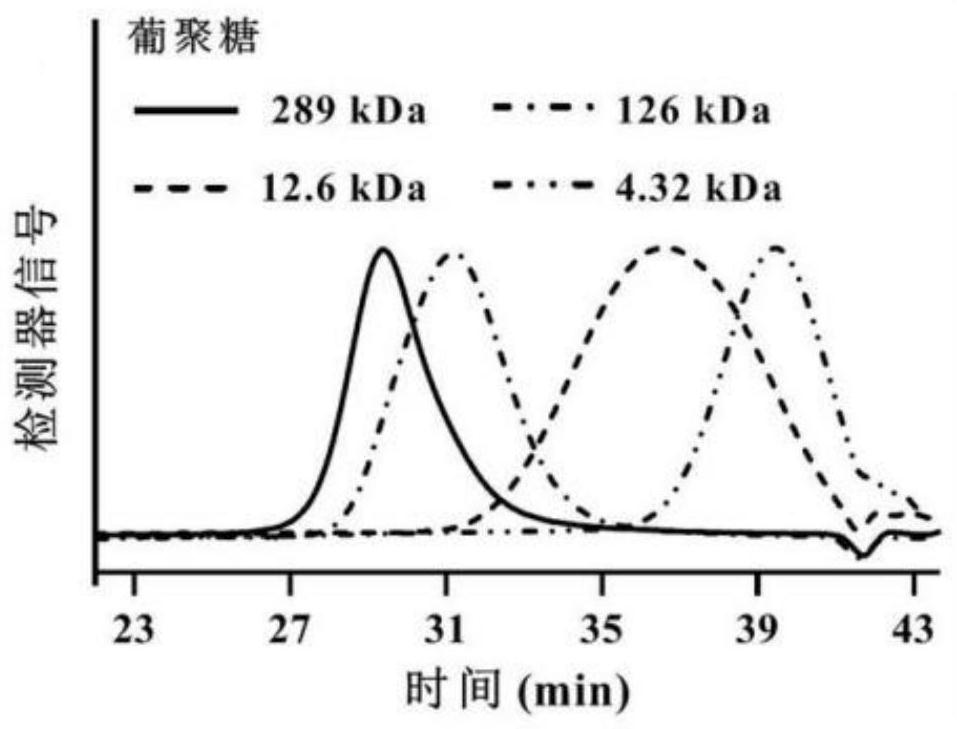

[0045] Test of molecular weight: Take a proper amount of sample well dissolved in 0.02 mol / l kh 2 PO 4 In the aqueous solution, the spare was filtered with 0.22 μm aqueous phase filter. Columns: TSK-Gel G-3000PWXL (7.8mm × 300mm I.D, 7 μm), TSK-Gel G-6000PWXL (7.8mm × 300mm I.D., 13μm), two columns in series; mobile phase 0.02mol / LKH 2 PO 4 The flow rate was 0.5 ml / min, the column temperature was 35 ± 1 ° C, and the sample was 25 μL. As standards of different molecular weight dextran (including 4.32 kDa, 12.6kda, 126kda and 289kda), the standardized molecular weight measurement results are as follows figure 1 Indicated.

[0046] The molecular weight measurement result...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com