Antistatic dustproof polyethylene multilayer fabric and preparation process thereof

A preparation process, polyethylene technology, applied in the direction of layered products, ester copolymer adhesives, synthetic resin layered products, etc., can solve the problems of flammability hindrance, antistatic agent falling off, flame retardancy reduction, etc. Achieve the effects of reducing intermolecular force, increasing hygroscopicity, and increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

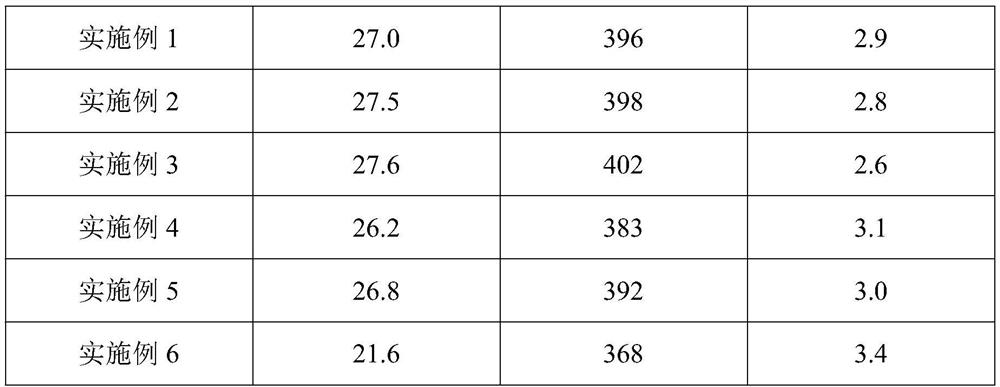

Embodiment 1

[0026] A preparation process for an antistatic and dustproof polyethylene multilayer fabric, comprising the following steps:

[0027] S1: Preparation of basic fabric: (1) Preparation of reduced graphene oxide / banana fiber: place banana stems in 1mL / L sulfuric acid with a bath ratio of 1:20 and set the temperature at 50°C for 40 minutes; Transfer to alkaline bath solution after washing and drying, bath ratio is 1:20, and alkaline bath solution is 30% 10g / L sodium hydroxide solution, 30% 0.1g / L magnesium sulfate solution, 35% 10g / L super Hydrogen oxide solution, 5% 0.05g / L reduced graphene oxide dispersion. Microwave heating for degumming and loading reduced graphene oxide, set the microwave power to 600W, heating temperature to 100°C, and time to 3 hours; after washing and drying, pickling, beating the fiber, and fluffing process to obtain reduced graphene oxide / banana fiber , standby; (2) 15 parts of reduced graphene oxide / banana fibers are mixed with 50 parts of polypropylen...

Embodiment 2

[0032] A preparation process for an antistatic and dustproof polyethylene multilayer fabric, comprising the following steps:

[0033] S1: Preparation of basic fabric: (1) Preparation of reduced graphene oxide / banana fiber: place banana stems in 1mL / L sulfuric acid with a bath ratio of 1:20, set the temperature at 50°C and process for 60 minutes; Transfer to alkaline bath solution after washing and drying, bath ratio is 1:20, and alkaline bath solution is 30% 10g / L sodium hydroxide solution, 30% 0.1g / L magnesium sulfate solution, 35% 10g / L super Hydrogen oxide solution, 5% 0.05g / L reduced graphene oxide dispersion. Microwave heating degumming and loading reduced graphene oxide, set the microwave power to 650W, heating temperature to 100°C, and time to 2 hours; after washing and drying, pickling, beating the fiber, and fluffing process to obtain the reduced graphene oxide / banana fiber , standby; (2) 22 parts of reduced graphene oxide / banana fibers are mixed with 60 parts of pol...

Embodiment 3

[0038] A preparation process for an antistatic and dustproof polyethylene multilayer fabric, comprising the following steps:

[0039] S1: Preparation of basic fabric: (1) Preparation of reduced graphene oxide / banana fiber: place banana stems in 1mL / L sulfuric acid with a bath ratio of 1:20, set the temperature at 50°C and process for 50 minutes; Transfer to alkaline bath solution after washing and drying, bath ratio is 1:20, and alkaline bath solution is 30% 10g / L sodium hydroxide solution, 30% 0.1g / L magnesium sulfate solution, 35% 10g / L super Hydrogen oxide solution, 5% 0.05g / L reduced graphene oxide dispersion. Microwave heating for degumming and loading reduced graphene oxide, set the microwave power to 620W, heating temperature to 100°C, and time for 2 to 3 hours; after washing and drying, pickling, beating fibers, and fluffing processes are performed to obtain reduced graphene oxide / Banana fiber, for subsequent use; (2) 18 parts of reduced graphene oxide / banana fibers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com