Material weighing and feeding device for metal working fluid production

A metalworking fluid and feeding device technology, applied in feeding devices, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as easy waste products, inconvenient operation, and incapable volume pumps, so as to save production work The effect of reducing the amount and time, simplifying the production process, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

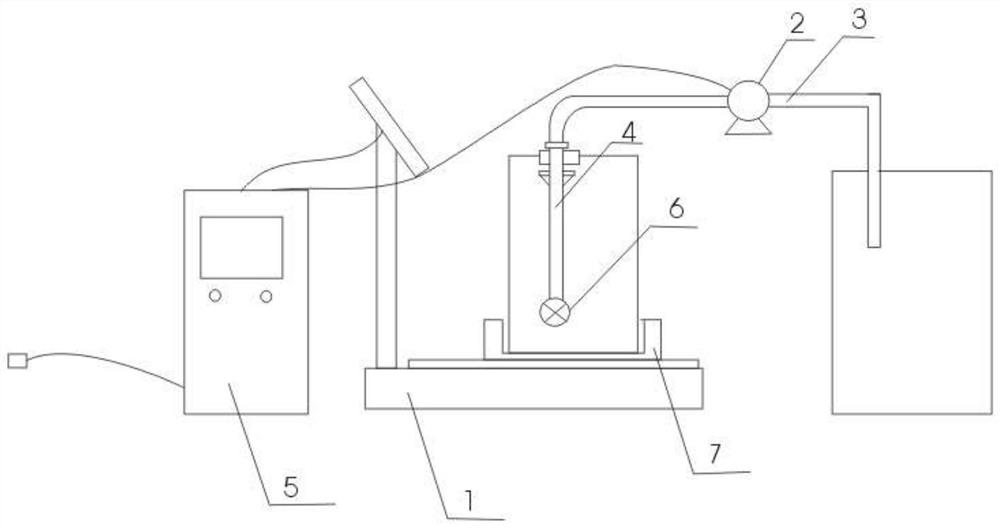

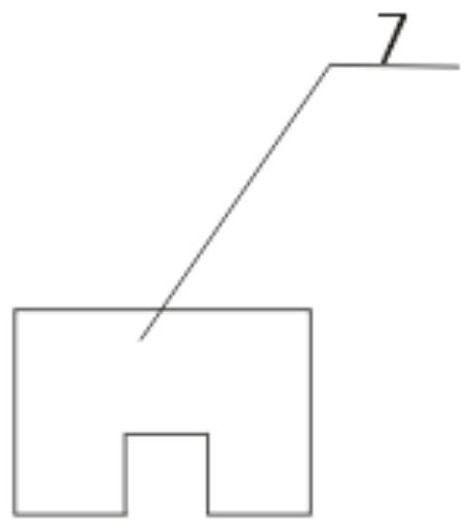

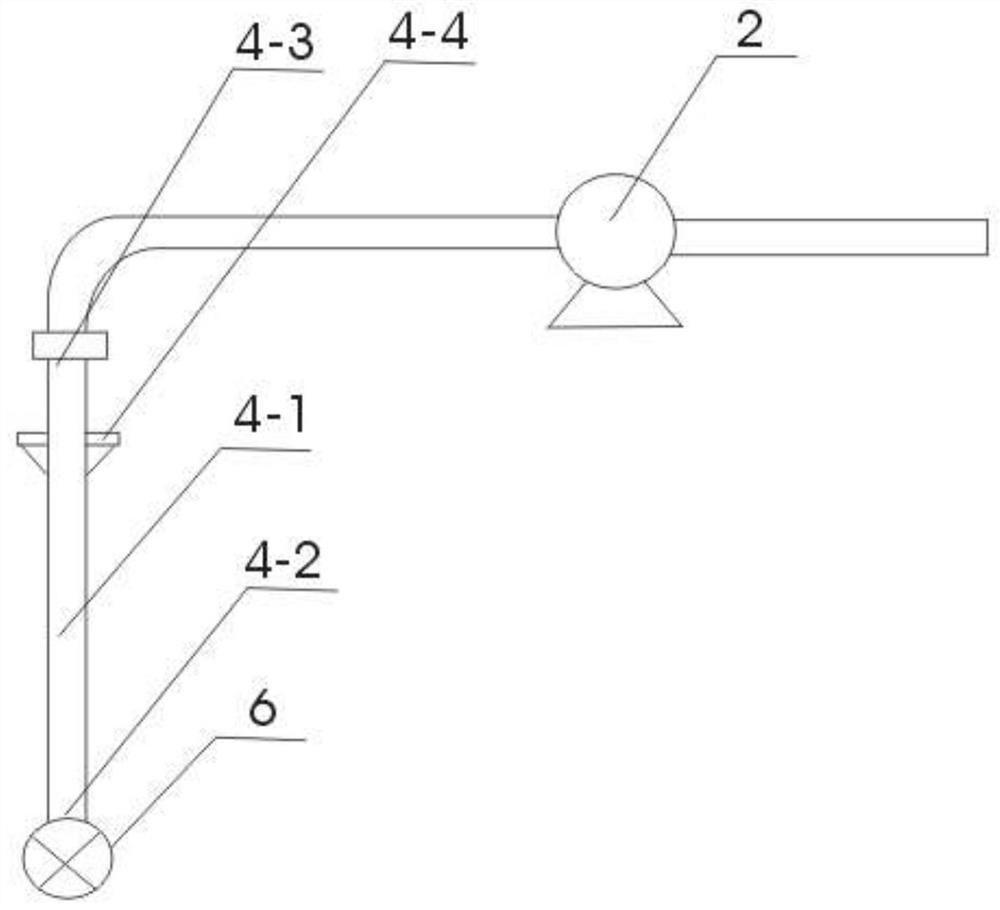

[0020] The invention provides a weighing and feeding device for metalworking fluid production, which is characterized in that it includes an electronic platform scale 1, a raw material pump 2, a pipeline 3, a material pumping pipe 4, a control electric box 5, a one-way valve 6, an electronic platform scale 1, a raw material The pump 2 is connected to the control electric box 5 respectively, and the control electric box 5 is connected to the external power supply. The electronic platform scale 1 is provided with a groove-7, and a raw material barrel is placed in the groove-7, and a material pumping pipe 4 is placed in the raw material barrel. A one-way valve 6 is installed on one end of the pumping pipe 4, and the one-way valve 6 is located in the raw material barrel. The other end of the pumping pipe 4 is connected to the inlet of the raw material pump 2 through a hose, and the outlet of the raw material pump 2 is connected to the reactor through a pipeline 3. The pumping pipe ...

Embodiment 2

[0022] During use, the raw material barrel is pushed onto the groove 7 of the electronic platform scale 1, and the raw material barrel is fixed by the groove 7 to avoid shaking of the raw material barrel, and then the pumping pipe 4 equipped with the check valve 6 is inserted into the raw material barrel, And keep it suspended in the air, not in contact with the barrel body, set the number of kilograms to be added on the touch screen, press the start button, the control electric box 5 will send the control command to the raw material pump 2, the raw material pump 2 starts, and the barrel The internal raw materials are transported into the stirred tank through the pumping pipe 4 and the pipeline 3 connected with the flexible pipe and the pumping pipe 4, and the system starts to perform subtraction. When the raw materials are extracted, the electronic platform scale 1 transmits the data to the controller of the electric box 5, and It is displayed on the display screen. When the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com