Bionic fiber functional material as well as preparation method and application thereof

A functional material and fiber technology, which is applied in the field of biomimetic fiber functional materials and its preparation, can solve the problems of difficult simultaneous removal of anionic and cationic heavy metal ions, low functional group density, and unbalanced functional group density. The effect of increasing the resistance of diffusion and mass transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

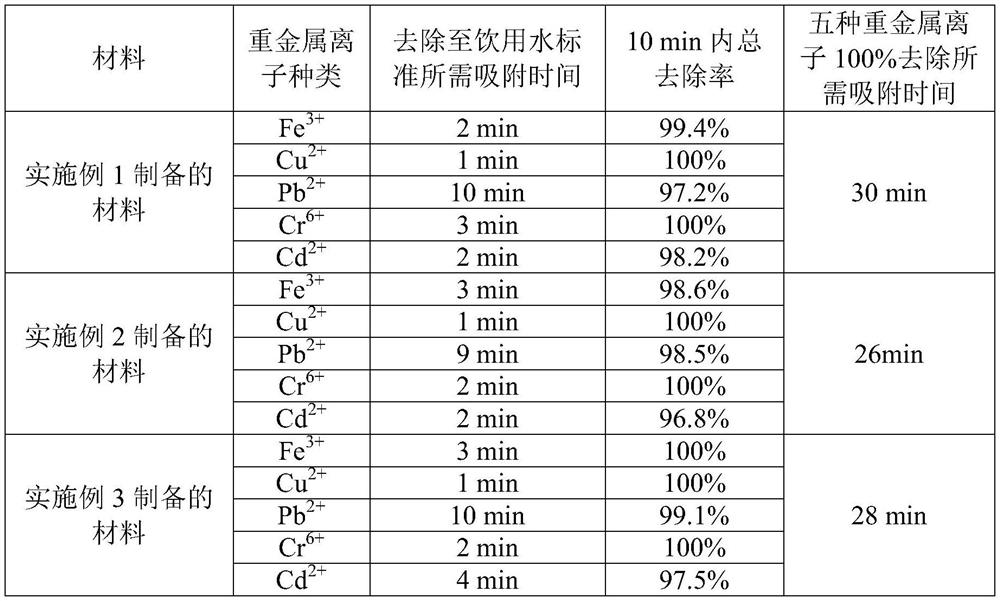

Examples

Embodiment 1

[0032] ①Preparation of carboxylated nanocellulose: Weigh 3g of dry bagasse pulp fiber in a 500mL three-neck flask, add 300mL of distilled water, and then add NaBr with a mole fraction of 5mmol / g dry bagasse pulp fiber to the bagasse pulp fiber mixture in turn. and TEMPO whose mole fraction is 0.5mmol / g absolute dry bagasse pulp fiber, then dropwise add a mass fraction of 10% NaOH solution to adjust the pH=10, and add an available chlorine mole fraction of 6mmol / g absolute dry bagasse pulp under the mixed liquid surface The NaClO solution of the fiber was fully mixed and reacted for 4 hours. During the reaction, the NaOH solution was continuously replenished to maintain the pH=10 until the pH no longer changed, and 10 mL of ethanol was added to terminate the reaction. The reaction product was taken out, the solution was centrifuged and washed until it was neutral, and no chloride ion was detected, and the product was stored at 4°C for future use.

[0033] ② Preparation of ethyl...

Embodiment 2

[0038] ①Preparation of carboxylated nanocellulose: Weigh 3g of dry bagasse pulp fiber in a 500mL three-necked flask, add 300mL of distilled water, and then add NaBr with a mole fraction of 3mmol / g dry bagasse pulp fiber to the bagasse pulp fiber mixture in turn. and TEMPO with a mole fraction of 0.3mmol / g absolute dry bagasse pulp fiber, then add dropwise a 20% NaOH solution to adjust the pH=10, and add an available chlorine mole fraction of 18mmol / g absolute dry bagasse pulp under the mixed liquid surface The NaClO solution of the fiber was thoroughly mixed and reacted for 6 hours. During the reaction, the NaOH solution was continuously replenished to maintain the pH=10 until the pH no longer changed, and 10 mL of ethanol was added to terminate the reaction. The reaction product was taken out, the solution was centrifuged and washed until it was neutral, and no chloride ion was detected, and the product was stored at 4°C for future use.

Embodiment 3

[0044] ①Preparation of carboxylated nanocellulose: Weigh 3g of dry bamboo pulp fiber in a 500mL three-neck flask, add 300mL of distilled water, and then add NaBr with a mole fraction of 1mmol / g of dry bamboo pulp fiber to the bamboo pulp fiber mixture. And mole fraction is 0.1mmol / g the TEMPO of absolute dry bamboo pulp fiber, then dropwise add the NaOH solution that mass fraction is 30% to adjust pH=10, add available chlorine mole fraction under the mixed liquid surface and be 30mmol / g absolute dry bamboo pulp The NaClO solution of the fiber was fully mixed and reacted for 8 hours. During the reaction, the NaOH solution was continuously replenished to maintain the pH=10 until the pH no longer changed, and 10 mL of ethanol was added to terminate the reaction. The reaction product was taken out, the solution was centrifuged and washed until it was neutral, and no chloride ion was detected, and the product was stored at 4°C for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com