Microbial agent for extracting copper from high-salt sulfurized electroplating sludge and extraction method

A technology of microbial agent and electroplating sludge, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as lack of salt tolerance, achieve good leaching effect, reduce wastewater treatment costs and the overall Process cost, effect of improving bioleaching function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

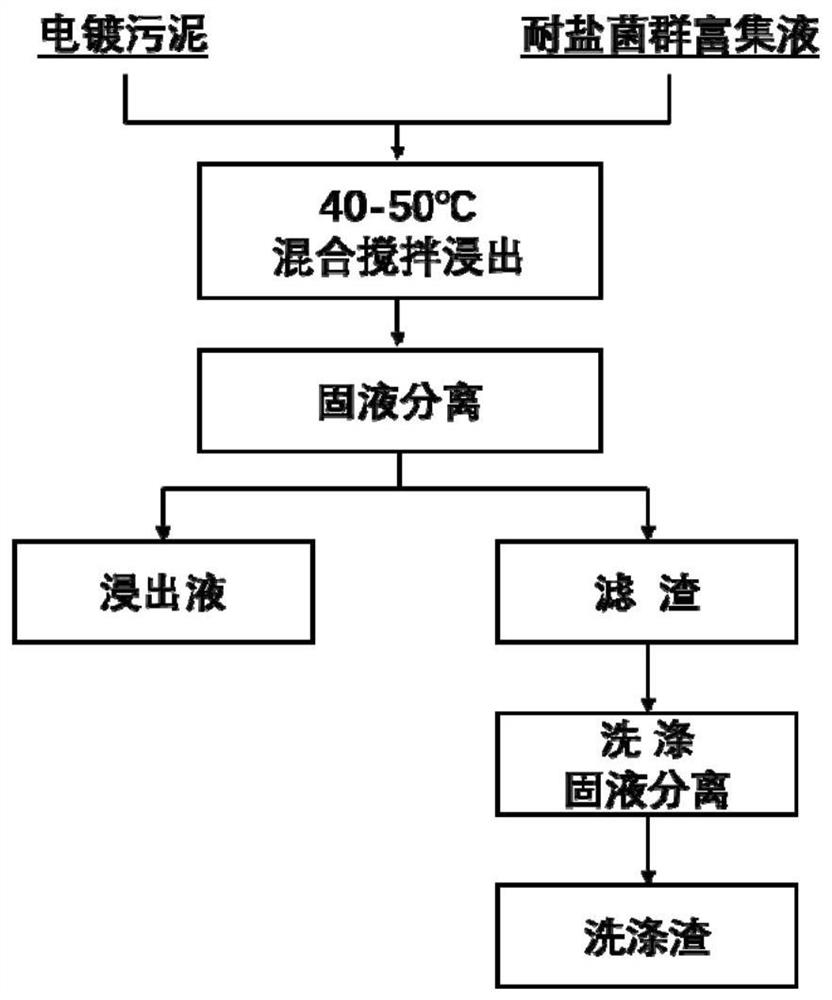

[0043] Using the high-salt sulfidation electroplating sludge produced by an electroplating factory as raw material, the biological flora constructed by the present invention is used to extract metallic copper. The steps are:

[0044] 1. The raw material of the high-salt sulfidation electroplating sludge was determined. Its moisture content was 55.34%, and its total copper content was 12.97%. It exists in the form of sulfide. As shown in Table 1.

[0045] Table 1

[0046]

[0047] 2. Weigh 450g of natural-based raw materials, add the microbial flora enrichment constructed in the present invention that meets the leaching requirements, so that the total leaching system reaches 2L, adjust the pH to about 2.0 with sulfuric acid, and use 350r / min at 50°C The stirring speed was stirred and leached for 4h.

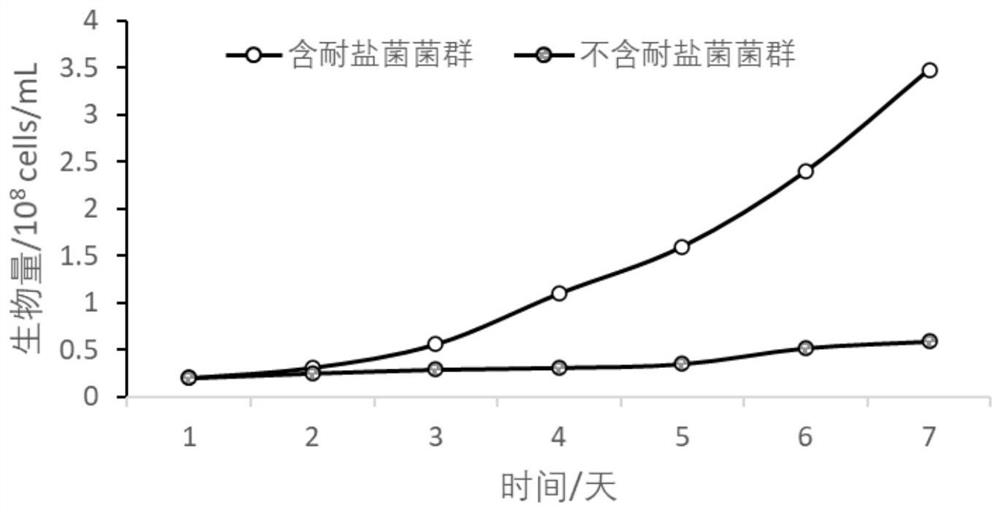

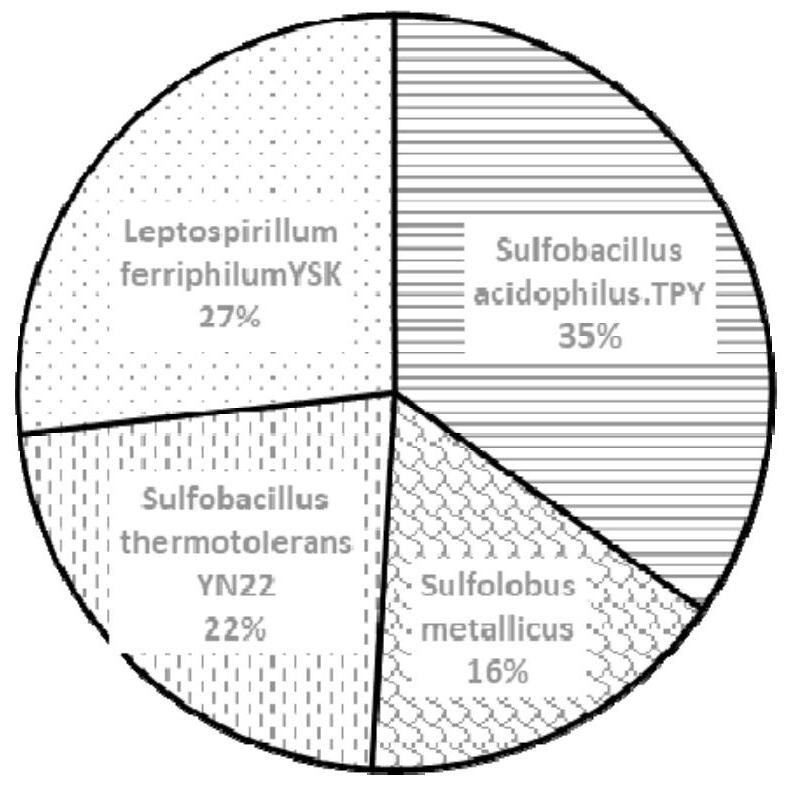

[0048] The culture method of microbial flora enrichment is as follows: the ratio of Sulfobacillus acidophilus.TPY: Sulfolobus metallicus JCM 9184: Sulfobacillus thermotoler...

Embodiment 2

[0054] The high-salt sulfidation copper-containing electroplating sludge produced by an electroplating factory is used as raw material, and the biological flora constructed by the present invention is used to extract metallic copper.

[0055] 1. The metal content of the raw material was determined, and the main metal element was copper, and the copper content was 10.60%.

[0056] 2. Weigh 50g of wet-based raw material, add the biological flora liquid that meets the leaching requirements, so that the total leaching system reaches 200mL, adjust the pH to 2.0 with sulfuric acid, stir and leaching at 40°C at a stirring speed of 300r / min for 2h. The cultivation method of the microbial flora enrichment is the same as in Example 1.

[0057] 3. The leached material in step 2 is subjected to solid-liquid separation by means of suction filtration to obtain leaching liquid and leaching residue.

[0058] 4. Collect the filter residue obtained in step 3, add 120mL of water, stir and wash ...

Embodiment 3

[0061] The high-salt sulfidation copper-containing electroplating sludge produced by an electroplating factory is used as raw material, and the biological flora constructed by the present invention is used to extract metallic copper.

[0062] 1. Determination of the metal content of the raw material shows that the main metal element is copper, and the copper content is 11.60%.

[0063] 2. Weigh 25Kg of wet-based raw materials, add the biological flora liquid that meets the leaching requirements, make the total leaching system reach 100L, adjust the pH to 2.0, stir and leaching at 300r / min at 45°C for 4h.

[0064] 3. Use a filter press to separate the solid-liquid from the leached material in step 2 to obtain leachate and leach residue.

[0065] 4. Collect the filter residue obtained in step 3, add 70L of clean water, stir and wash at 50°C at a stirring speed of 300r / min for 1h, and separate the solid and liquid. This step is repeated once.

[0066] 5. Take an appropriate amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com