Mesona herb polysaccharide/nano TiO2/hyacinth bean starch multifunctional composite film and preparation method thereof

A technology of jelly grass and composite film, which is applied in the direction of sustainable manufacturing/processing, flexible coverings, biological packaging, etc., can solve problems such as shortage, environmental pollution, and no application of starch film products found, and achieve low production cost, Good hydrophobicity and good economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

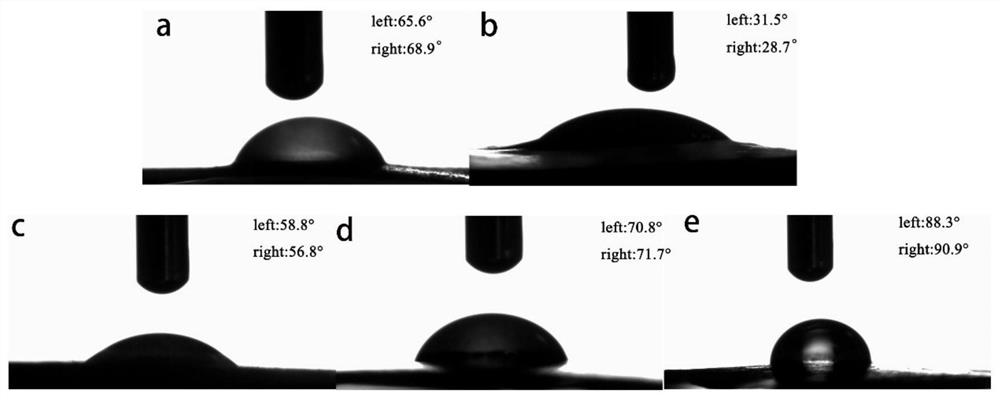

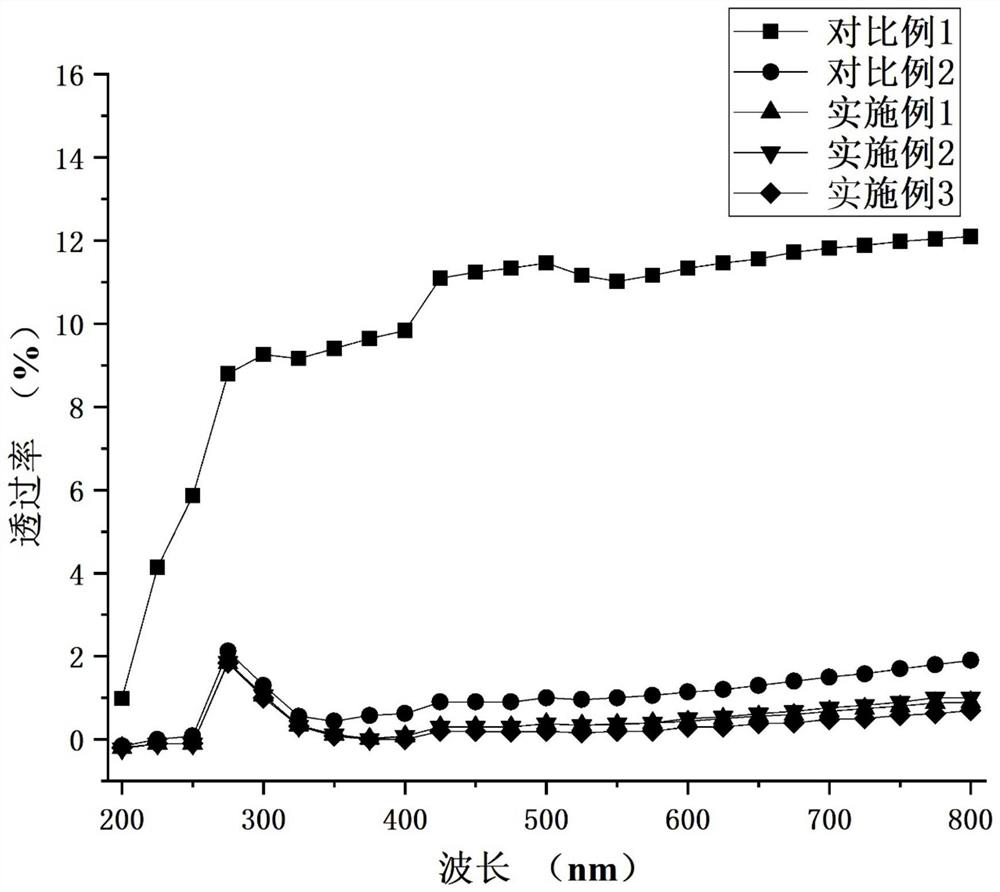

Embodiment 1

[0025] (1) Extraction of Cold Grass Polysaccharide: Weigh quantitative fresh and cold powder, add deionized water (from 1:10) and 1.2% (w / v) sodium hydrogencarbonate, at 90 ° C in a constant temperature water bath Break 1 h, after cooling, filter with 400 mesh gauze, remove the upper filter residue, to obtain brown sewer polysaccharide, place it at 4 ° C refrigerator spare.

[0026] (2) Pastening: 2g 淀 淀, 0.6 g of glycerin and 0.02 g of condolences and mix, mixed with 40 ml of deionized water, and heated to observe the system adequate gelation of 90 ° C water bath.

[0027] (3) Formation liquid prepared: 0.04 g of nano Tio dispersed from deionized water after gelatinization 2 After mixing is uniform, the bubbles generated by ultrasound 30 minutes to remove genia and make nano TiO 2 It is fully dispersed in the system.

[0028] (4) Water cast film: Evenly pour the film-forming liquid in step (3) on the Teflon mold, add 50 ° C oven for 5 hours, take out the mold, and uncover the c...

Embodiment 2

[0030] (1) Extraction of Cold Grass Polysaccharide: Weigh quantitative fresh and cold powder, add deionized water (from 1:10) and 1.2% (w / v) sodium hydrogencarbonate, at 90 ° C in a constant temperature water bath Break 1 h, after cooling, filter with 400 mesh gauze, remove the upper filter residue, to obtain brown sewer polysaccharide, place it at 4 ° C refrigerator spare.

[0031] (2) Pastening: 2g 淀, 0.6 g of glycerol and 0.04 g of condolences and mix, mixing with 40 ml of deionized water and mixed with 40 ml of water bath and heating to observe the full gelation of the system.

[0032] (3) Formation liquid prepared: 0.04 g of nano Tio dispersed from deionized water after gelatinization 2 After mixing is uniform, the bubbles generated by ultrasound 30 minutes to remove genia and make nano TiO 2 It is fully dispersed in the system.

[0033] (4) Water cast film: Evenly pour the film-forming liquid in step (3) on the Teflon mold, add 50 ° C oven for 5 hours, take out the mold, a...

Embodiment 3

[0036] (1) Extraction of Cold Grass Polysaccharide: Weigh quantitative fresh and cold powder, add deionized water (from 1:10) and 1.2% (w / v) sodium hydrogencarbonate, at 90 ° C in a constant temperature water bath Break 1 h, after cooling, filter with 400 mesh gauze, remove the upper filter residue, to obtain brown sewer polysaccharide, place it at 4 ° C refrigerator spare.

[0037] (2) Pastening: 2g of 2 g of lentil starch, 0.6 g of glycerol and 0.08 g of condolences and polysaccharides were mixed, and 40 ml of deionized water was mixed, and heated at a 90 ° C water bath and heated to observe the system full gelation.

[0038] (3) Formation liquid prepared: 0.04 g of nano Tio dispersed from deionized water after gelatinization 2 After mixing is uniform, the bubbles generated by ultrasound 30 minutes to remove genia and make nano TiO 2 It is fully dispersed in the system.

[0039] (4) Water cast film: Evenly pour the film-forming liquid in step (3) on the Teflon mold, add 50 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com