Polyaniline modified carbon fiber composite material as well as preparation method and application thereof

A composite material and carbon fiber technology, applied in the field of carbon fiber surface treatment, can solve the problems of manufacturing carbon fiber composite materials, achieve good wettability, huge application advantages, and enhanced interface polarization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

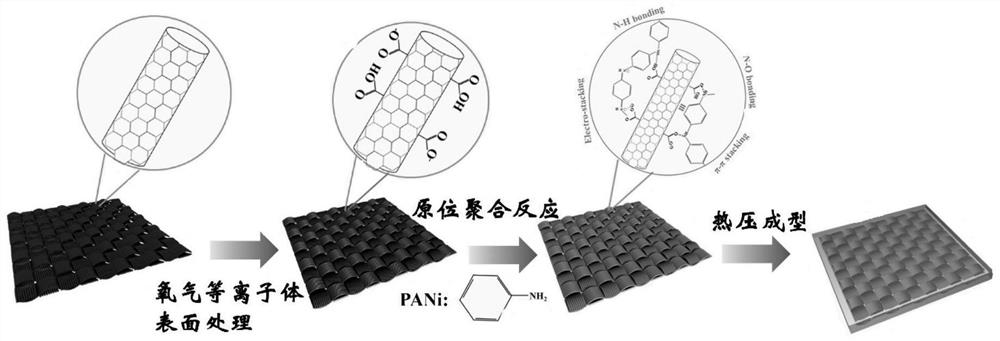

[0042] Such as figure 1 As shown, a preparation method of a polyaniline-modified carbon fiber composite material with excellent interfacial properties and electromagnetic shielding properties includes:

[0043] (1) Soak the carbon fibers in acetone for 48-72 hours to remove the size and then dry them in an oven at 80°C for later use. The selected carbon fibers are preferably carbon fiber cloth, and the size is not specifically limited. It is preferably cut to 100×100mm;

[0044] (2) Oxygen plasma surface treatment is carried out on the carbon fiber (PCF) after desizing, the treatment power is preferably 400-600W, and the treatment time is preferably 5-10min;

[0045] (3) Prepare an aniline monomer dispersion containing a dopant, put the carbon fiber (OCF) obtained in step (2) into the aniline monomer solution for pre-soaking, and the pre-soaking time is preferably 60-120min;

[0046] The dopant is hydrochloric acid, sulfuric acid, phosphoric acid, sulfosalicylic acid, camphor...

Embodiment 1

[0051] Concrete process steps adopt:

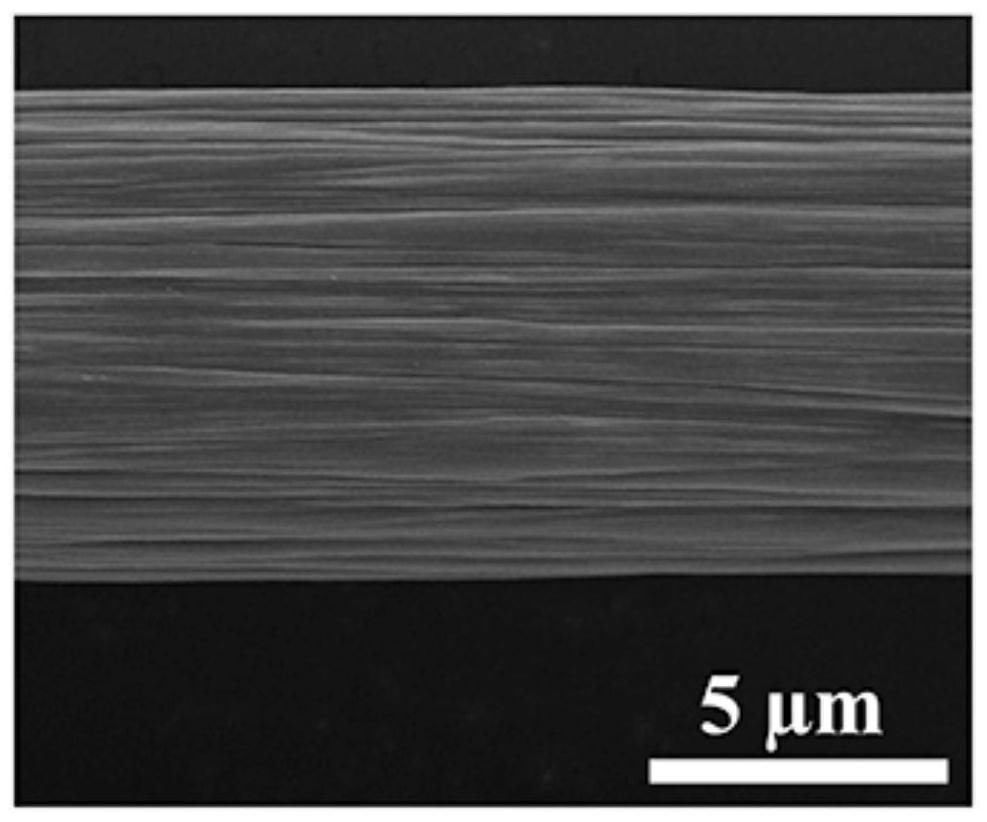

[0052] (1) Cut the carbon fiber cloth into 100×100mm, soak it in acetone for 72 hours to remove the size, and then dry it in an oven at 80°C for later use;

[0053] (2) Carry out oxygen plasma surface treatment to the carbon fiber (PCF) after desizing, the treatment power is 600W, and treatment time is 10min;

[0054] (3) Disperse 0.09mol of aniline monomer in 200ml of 1mol / L hydrochloric acid solution to prepare aniline monomer solution, and immerse the carbon fiber (OCF) obtained in step (2) in the aniline solution for 2 hours to fully absorb the aniline monomer on the carbon fiber surface;

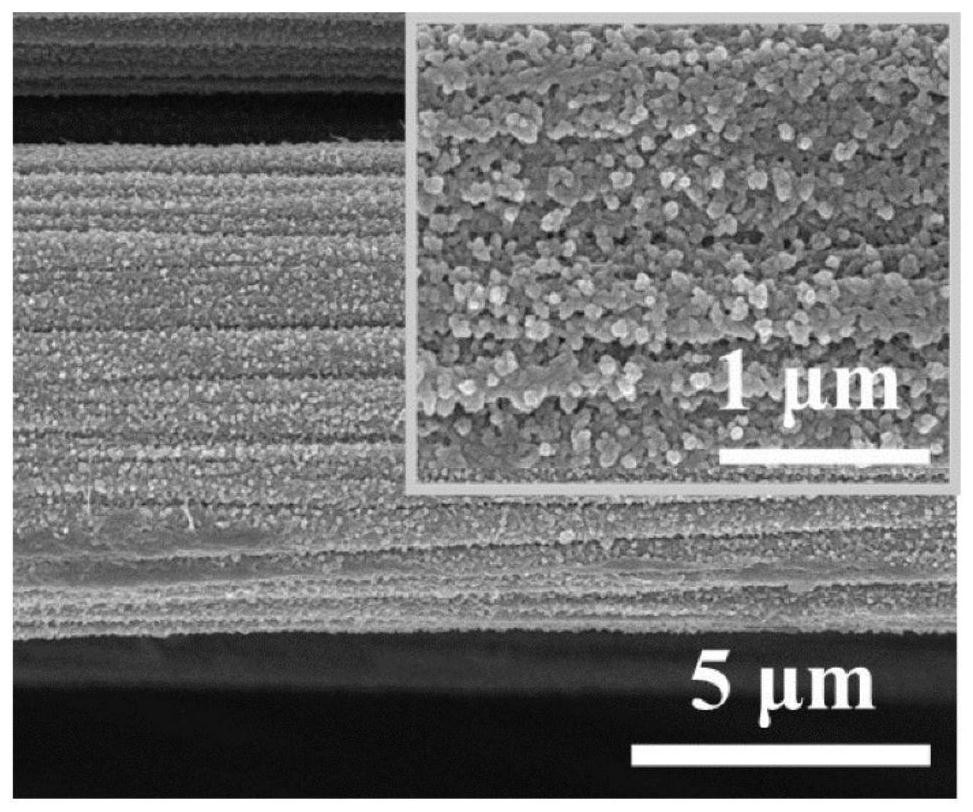

[0055] (4) Disperse 0.045mol of ammonium persulfate in 200ml of 1mol / L hydrochloric acid solution to prepare an initiator solution. After pre-cooling, slowly add to the aniline monomer solution obtained in step 3 and stir evenly. Aniline monomer solution occurs near 0°C. The in-situ polymerization reaction of body on carbon fiber surface, the pol...

Embodiment 2

[0058] The steps of this example are basically the same as those of Example 1, except that the polyaniline polymerization time in step (4) is 3.0 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com