Concrete with a bulk density exceeding 5,000 kilograms per cubic meter and its preparation method

A concrete and bulk density technology, which is applied in the field of concrete materials, can solve the problems of affecting the cohesion and water retention of concrete, the adverse effect of heavy concrete construction performance, and the high aggregate density, etc., to improve the workability of the product, excellent penetration and emulsification , the effect of reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

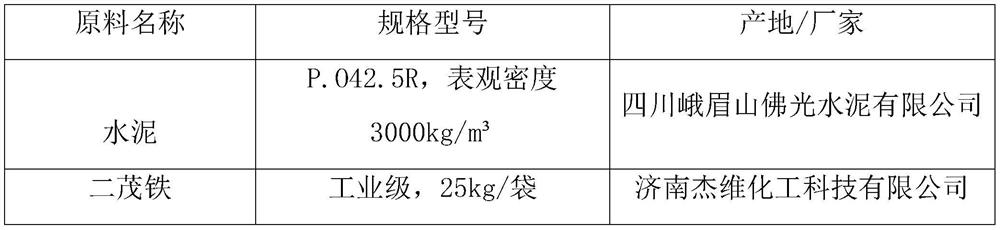

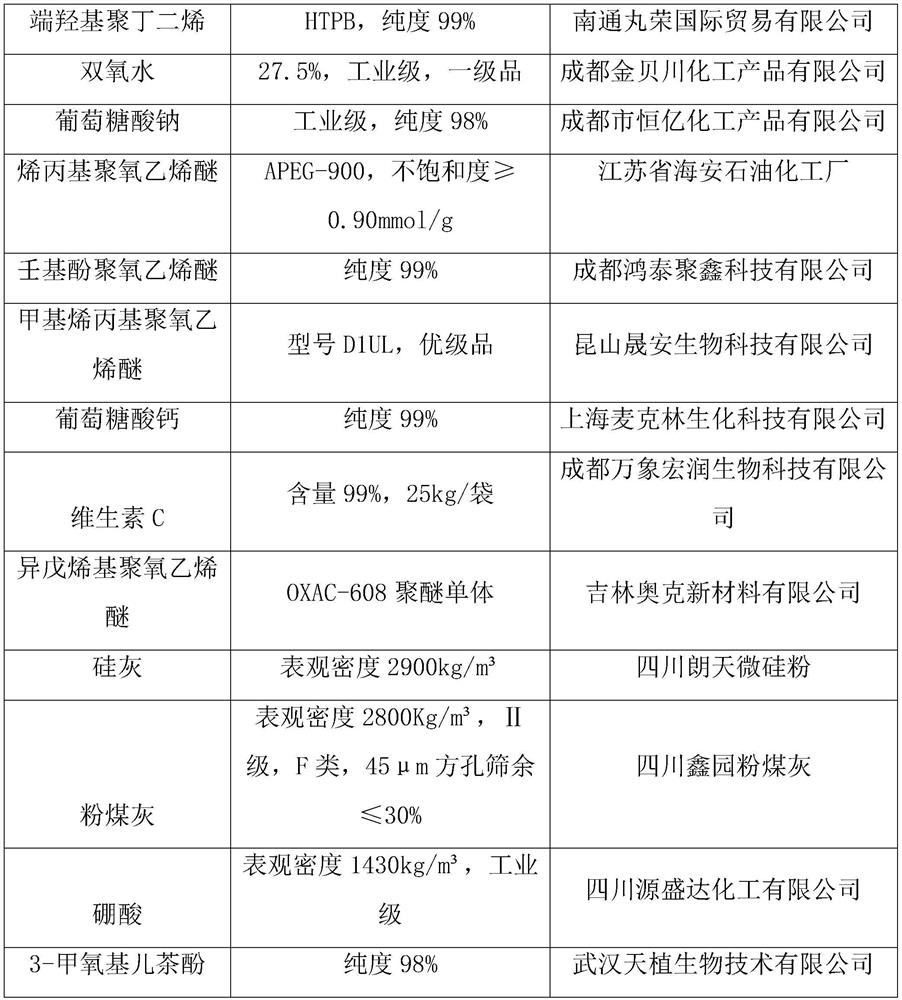

[0033] The raw materials involved in this application are all commercially available, and the models and sources of the raw materials are shown in Table 1.

[0034] Table 1 Specifications, Models and Sources of Raw Materials

[0035]

[0036]

[0037] The iron sand used in the following examples is provided by Henan Tengze Environmental Protection Technology Co., Ltd. There are two specifications, one with an apparent density of 6820kg / m 3 , fineness 3.3; the other is the apparent density of 7550kg / m 3 , fineness 3.1.

preparation example 1

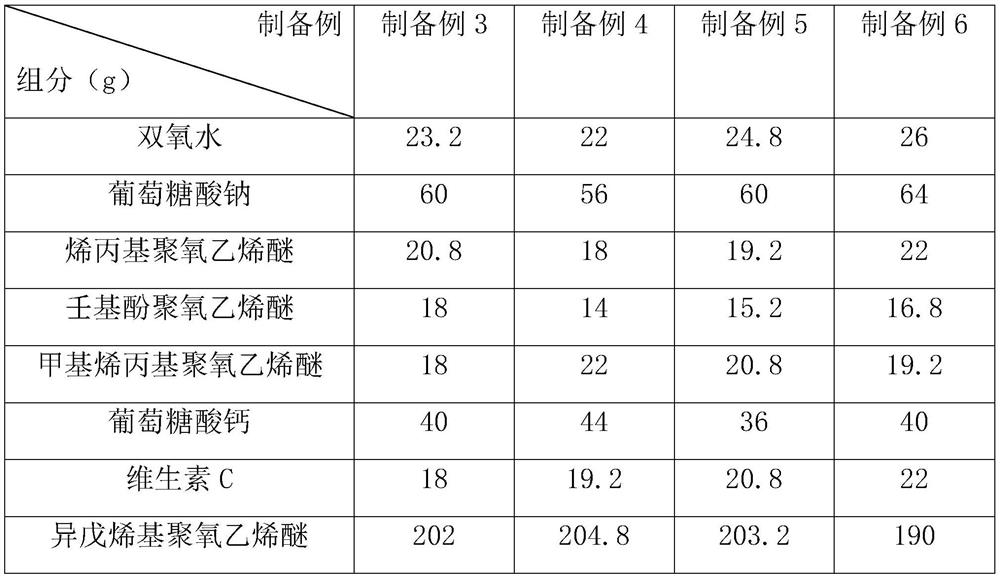

[0039] Preparation example 1: the preparation method of additive, comprises the steps:

[0040] Weigh 2.5kg of isopentenyl polyoxyethylene ether, stir at a speed of 100 rpm, heat to 90°C, add 700g of nonylphenol polyoxyethylene ether, add 300g of hydrogen peroxide dropwise at a constant speed for 60min, keep stirring for 120min; cool down To 55°C, add 250g of vitamin C, 750g of sodium gluconate and 500g of calcium gluconate, and continue stirring for no less than 20 minutes to prepare the admixture.

preparation example 2

[0041] Preparation example 2: the preparation method of additive, comprises the steps:

[0042] Weigh 2.5kg of isopentenyl polyoxyethylene ether, stir at a speed of 100 rpm, heat to 90°C, add 250g of allyl polyoxyethylene ether, 200g of nonylphenol polyoxyethylene ether and 250g of methyl alkene Propyl polyoxyethylene ether, add 300g of hydrogen peroxide dropwise at a constant speed for 60 minutes, keep stirring for 120 minutes; cool down to 55°C, add 250g of vitamin C, 750g of sodium gluconate and 500g of calcium gluconate, and continue stirring for no less than 20 minutes to prepare the admixture . Referring to GB / T8077-2012 "Concrete Admixture Homogeneity Test Method", the water-reducing rate was tested, and the water-reducing rate of the admixture prepared in Preparation Example 2 was 35%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com