Recycling device for electroplating wastewater treatment

A technology for electroplating wastewater and recycling, which is applied in metallurgical wastewater treatment, water/sewage treatment, flotation water/sewage treatment, etc. It can solve the problems of incapable of simultaneous treatment of pollutants, ineffective use of water, and increased treatment costs. , to shorten the granulation time, improve the treatment efficiency, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

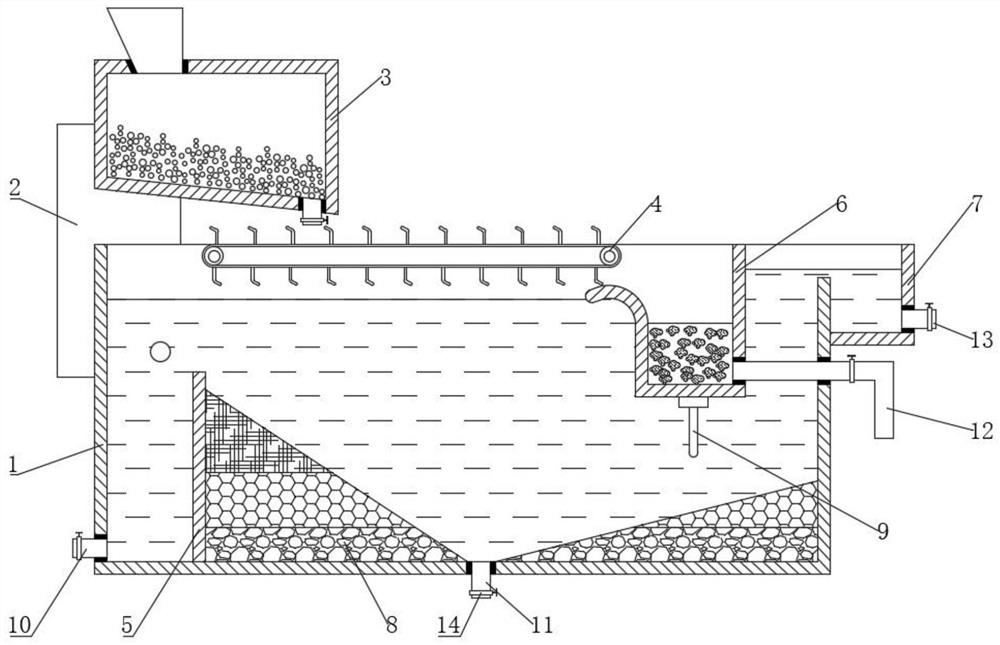

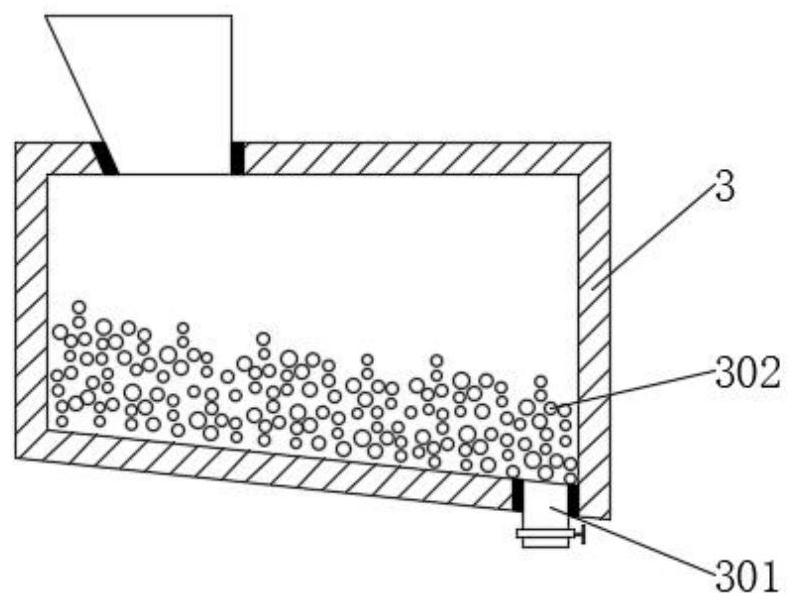

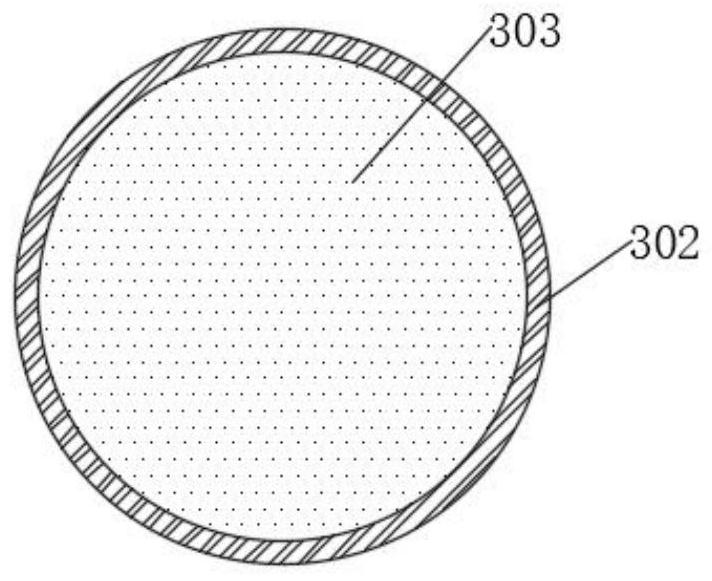

[0051] see Figure 1-8 , a recycling device for electroplating wastewater treatment, a recycling device for electroplating wastewater treatment, including a treatment pool 1, a reducing agent box 2 is fixedly installed at the rear end of the treatment pool 1, and the reducing agent box 2 is located on the left side of the treatment pool 1 , the upper end of the treatment pool 1 is fixedly installed with a neutralization exhaust box 3 located at the front side of the reducing agent box 2, and the upper end of the treatment pool 1 is provided with a scraper assembly 4 located at the lower side of the neutralization exhaust box 3, and the reducing agent box 2 stores There is a ferrous sulfate solution, and a chemical film 302 is stored in the neutralizing exhaust box 3, and a neutralizing chemical 303 is wrapped in the chemical film 302. The electroplating wastewater containing chromium ions in the treatment pool 1 is treated by the ferrous sulfate solution in the reducing agent ...

Embodiment 2

[0062] see Figure 1-8 , where the same or corresponding components as those in Embodiment 1 use the corresponding reference numerals as in Embodiment 1, and for the sake of simplicity, only the differences from Embodiment 1 will be described below. The difference between this embodiment 2 and embodiment 1 is: please refer to Figure 8 , a treatment method of a recycling device for electroplating wastewater treatment, comprising the steps of:

[0063] S1. Pass the ferrous sulfate solution in the reducing agent box 2 into the treatment pool 1 in advance;

[0064] S2. make the ferrous sulfate solution react with the hexavalent chromium ion in the treatment pool 1, and carry out redox to the hexavalent chromium ion;

[0065] S3. Then start the scraping and floating assembly 4 to make the treatment pool 1 rotate and run at the upper end of the treatment pool 1;

[0066] S4. Finally, the chemical film 302 in the neutralization exhaust box 3 is dropped on the scraper assembly 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com