Three-dimensional light-to-heat conversion material, device and method capable of efficiently treating brine and wastewater

A photothermal conversion material and photothermal conversion technology, applied in chemical instruments and methods, seawater treatment, water/sewage treatment, etc. Energy input and other issues, to achieve excellent water dispersion performance, continuous high-efficiency evaporation, and high-efficiency evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

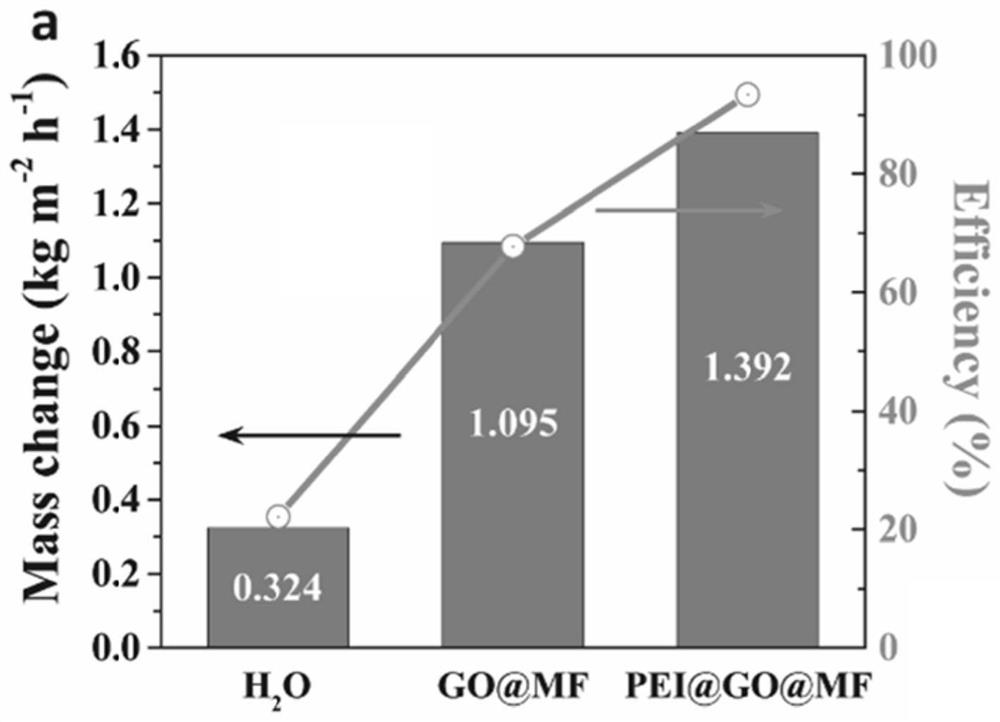

[0064] In this example, the light-to-heat conversion efficiency of the three-dimensional light-to-heat conversion material is evaluated, as follows:

[0065] 1) A certain volume of water is added to the water storage device, and a thermal insulator (polystyrene foam), a water-absorbing layer (non-woven fabric) and a three-dimensional light-to-heat conversion material are sequentially placed on it, which is the evaluation of the light-to-heat conversion efficiency used. Simulator.

[0066] 2) Simulation device for evaluating photothermal conversion efficiency by simulating the vertical irradiation of sunlight, through the online quality detection system, recording the change of quality over time, collecting data to calculate the photothermal evaporation rate per unit area, normalizing the input value of light energy, and calculating Light-to-heat conversion efficiency. The specific process is as follows:

[0067] ① Under the condition of no light irradiation, conduct a balanc...

Embodiment 2

[0073] Step 1: Adjust the pH of 19.5 mL of 7.7 mg / mL graphene oxide solution to 12 to obtain solution A. Polyethyleneimine was used to prepare a polymer electrolyte solution with a concentration of 15 mg / mL to obtain solution B.

[0074] Add solution B dropwise to solution A, so that the ratio of graphene oxide to polymer electrolyte (abbreviated as GO: POLYMER) = 3:1 ~ 3:12, the remaining volume is made up with distilled water, shake vigorously or ultrasonically It is fully mixed to obtain a charged graphene oxide composite solution.

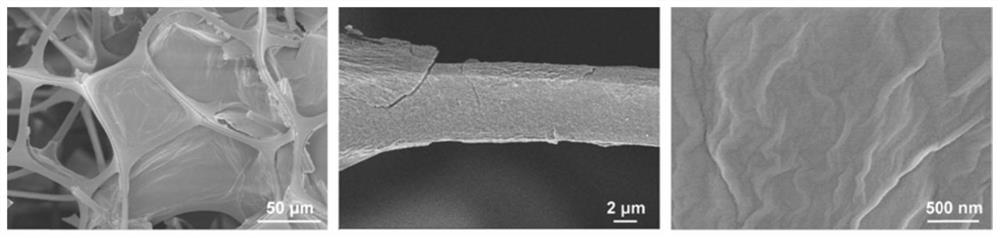

[0075] Step 2: Cut the block melamine foam into a 4cm×4cm×1cm cuboid (example), dip it in water and ethanol for several times, and then put it in a 60-degree oven to dry overnight. Get a clean and dry lather.

[0076] Step 3: Weigh the quality of clean and dry foam, select foam with similar quality, and immerse it in the solution of GO:POLYMER=3:1, 3:3, 3:6, 3:9, 3:12 respectively, Through extrusion-impregnation, the foam can fully absorb th...

Embodiment 3

[0086] The method of preparing a three-dimensional photothermal converter is shown in Example 2. A small rectangular opening of 5mm*5 mm is formed in the middle of the photothermal converter by using a ring knife, and 20wt% of simulated seawater is treated with an intermediate water supply method, and the light intensity is 1kw m 2 .

[0087] The results show that the water evaporation rate and photothermal conversion efficiency of the three-dimensional photothermal converter have not decreased after 12 hours of continuous operation, and the salt crystals mainly appear on the edge of the light absorber. out of the light absorber.

[0088] Table 2 The actual treatment effect of the light absorber in the intermediate water supply on high-concentration seawater

[0089]

[0090]

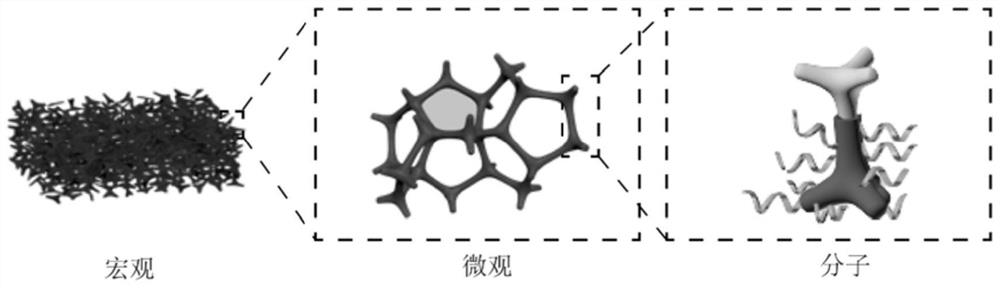

[0091] The results of the examples show that the three-dimensional light-to-heat conversion material synthesized by graphene oxide, polymer electrolyte, and melamine foam has excellent light abso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com