Preparation method and application of porous carbon dot material based on industrial glucose

A technology of porous carbon and glucose, which is applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of complex preparation process and achieve the effects of simple production process, high yield and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] A kind of preparation method of the porous carbon dot material based on industrial glucose, comprises the following steps:

[0033] Step 1: Directly heat industrial glucose to synthesize the precursor of porous carbon dot material, the synthesis temperature is S°C, and the time is Tmin;

[0034] Step 2: Mix the precursor prepared in step 1 with KOH at a mass ratio of X;

[0035] Step 3: Heat the material obtained in Step 2 under an argon atmosphere to activate and carbonize it. The heating rate is V°C / min, and the temperature is raised to S 1 It was kept at ℃ for 2 hours, and finally cooled to room temperature to obtain a crude product, which was further washed with 0.3% dilute hydrochloric acid solution and water to neutrality, and dried to obtain a porous carbon dot material.

[0036]

[0037] Table 1

[0038] As shown in Table 1:

Embodiment 1

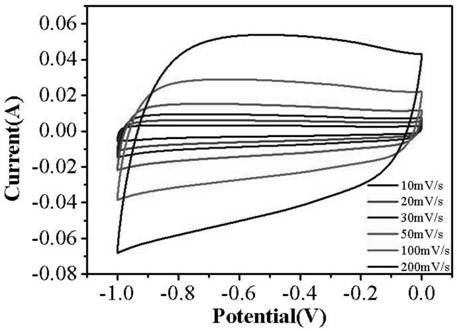

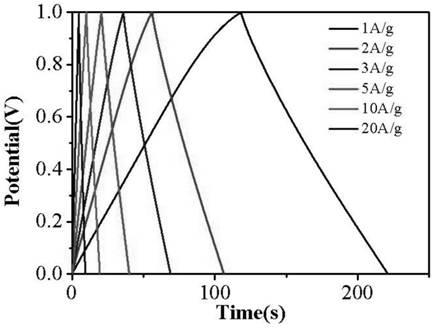

[0051] For Example 1, under the three-electrode system, the electrode sheet is used as the working electrode, the Pt sheet is used as the counter electrode, and the Hg / HgO electrode is used as the reference electrode to form a three-electrode system, using a CHI760E electrochemical workstation (CHI Instrument Company) in 3M KOH , carry out electrochemical tests at different scan speeds of 10-200mV / s, and obtain CV curves, the results are as follows Figure 4 shown. Then carry out the electrochemical test under the condition of 1 ~ 20A / g constant current charge and discharge, obtain the constant current charge and discharge curve, the results are as follows Figure 5 shown.

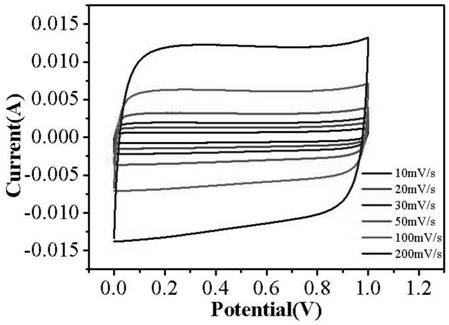

[0052] For Example 1, under the two-electrode system, 3 M KOH solution was used as the electrolyte, and nickel foam with a difference in the loading mass of the active material of less than 0.3 mg was used as the positive and negative electrodes respectively, and they were separated by a water-based diaph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com