Modified regenerated PVB composite laminated fabric and preparation method thereof

A composite layer and fabric technology, applied in the field of modified and recycled PVB composite laminated fabric and its preparation, can solve the problems of low bonding strength, harsh production environment, complicated production process, etc., achieve complete and firm coating, and improve the market. The effect of competitiveness and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

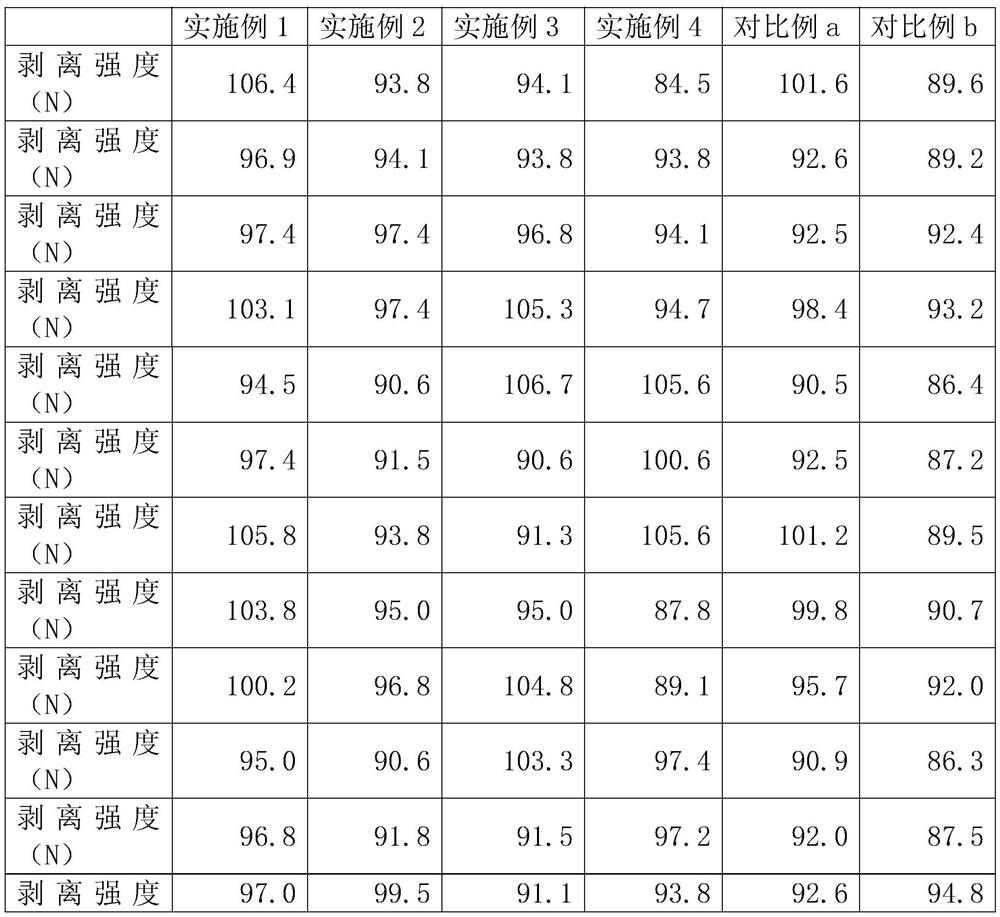

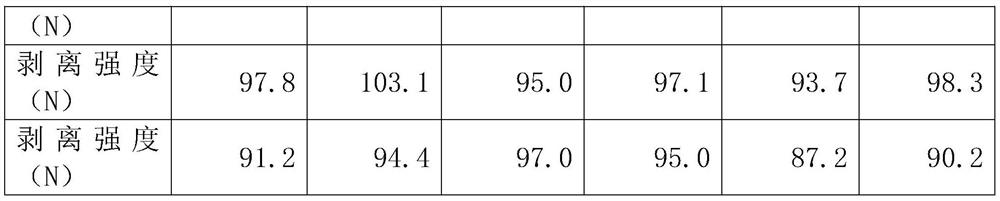

Examples

Embodiment 1

[0034] Embodiment 1: Embodiment 1: raw material is prepared as follows: reclaim 80 parts of PVB material, 10 parts of butanediol diglycidyl ether, 2 parts of succinic anhydride, 15 parts of calcium carbonate, plasticizer triethylene glycol diisocaprylate 4 parts, 0.2 parts each of antioxidant 1010 and 168, 0.3 parts of aminopropyltriethoxysilane, and the fabric layer is made of polyester cloth. Concrete preparation process is as follows:

[0035] 1) Put 4 parts of triethylene glycol diisocaprylate, 15 parts of calcium carbonate and 0.3 parts of aminopropyltriethoxysilane into a high-speed mixer, mix and stir for 5 minutes, then add 80 parts of PVB and 0.2 parts each of antioxidant 1010 and 168, mixed and stirred for 10 minutes to obtain the mixed raw material for PVB film preparation; the above mixed raw material was added to a twin-screw extruder, extruded at an extrusion temperature of 170 ° C, and tape-cast , to obtain PVB film;

[0036] 2) After putting the fabric layer ...

Embodiment 2

[0039] Embodiment 2: The raw materials are prepared as follows: 75 parts of recycled PVB materials, 5 parts of trimethylol triglycidyl ether, 1 part of maleic anhydride, 18 parts of aluminum oxide, 2 parts of plasticizer dioctyl adipate, antioxidant Agents 1010, 168, 0.2 parts each, 0.9 parts of methacryloxytriethoxysilane, and the fabric layer is made of cotton cloth. Concrete preparation process is as follows:

[0040] 1) Put 2 parts of dioctyl adipate, 18 parts of aluminum oxide and 0.9 part of methacryloxytriethoxysilane into the high-speed mixer, mix and stir for 10 minutes, and then add PVB75 into the high-speed mixer part and 0.2 parts of antioxidant 1010 and 168 respectively, mixed and stirred for 8 minutes to obtain the mixed raw material prepared by PVB film; the above mixed raw material was added to a twin-screw extruder, extruded at an extrusion temperature of 160 ° C, and co-flowed Extensive forming to obtain PVB film;

[0041] 2) After putting the fabric layer ...

Embodiment 3

[0045] The raw materials are prepared as follows: 60 parts of recovered PVB material, 2 parts of pentaerythritol tetraglycidyl ether, 0.5 part of tetrahydrophthalic anhydride, 39 parts of talcum powder, 1 part of plasticizer dioctyl sebacate DOS, antioxidant 1010, 0.2 part each of 168, 0.5 part of antioxidant IRGANOX10100, 0.5 part of ultraviolet absorber benzophenone, 0.4 part of vinyltrimethoxysilane, and the fabric layer is made of blended fabric of polyester and cotton. Concrete preparation process is as follows:

[0046] 1) Put 1 part of dioctyl sebacate DOS, 39 parts of talc powder and 0.4 part of vinyltrimethoxysilane into the high-speed mixer, mix and stir for 8 minutes, then add 60 parts of PVB and antioxidant to the high-speed mixer 0.2 parts each of 1010 and 168, 0.5 parts of antioxidant IRGANOX10100, 0.5 part of ultraviolet absorber benzophenone, mixed and stirred for 10 minutes to obtain the mixed raw materials prepared by PVB film; the above mixed raw materials w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com