Ferrite stainless hot-rolled-and-annealed steel sheet and production method for same

A manufacturing method and technology of stainless steel, which can be applied to manufacturing tools, heat treatment furnaces, heat treatment equipment, etc., can solve problems such as inability to properly manufacture flange parts, cracks, etc., and achieve the effects of excellent blanking workability and sufficient corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] Hereinafter, the present invention will be described in detail through examples.

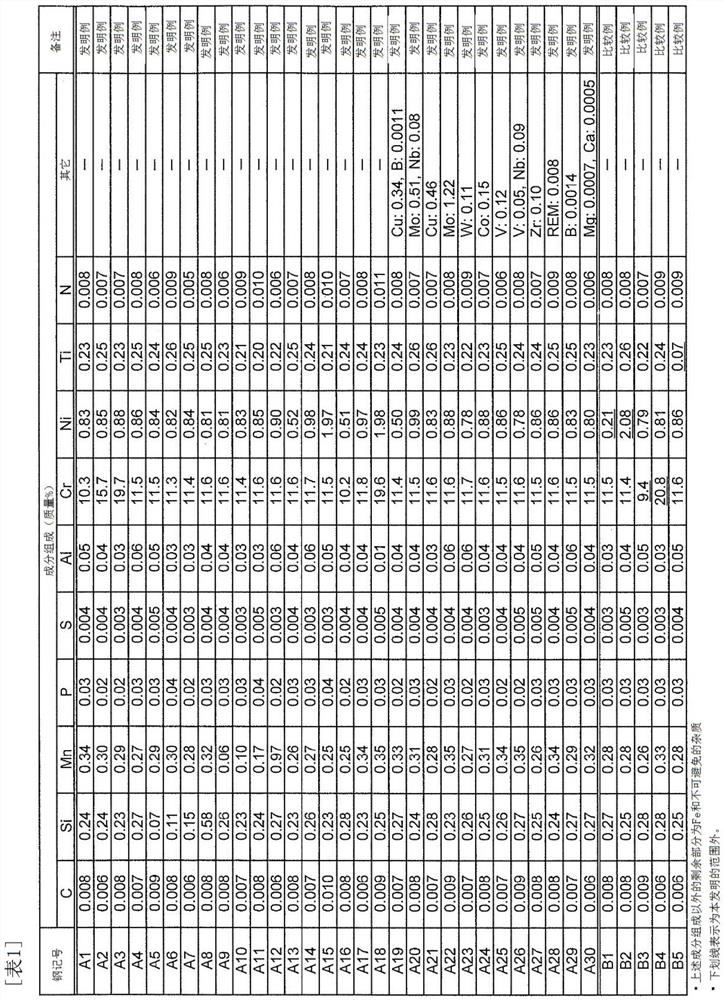

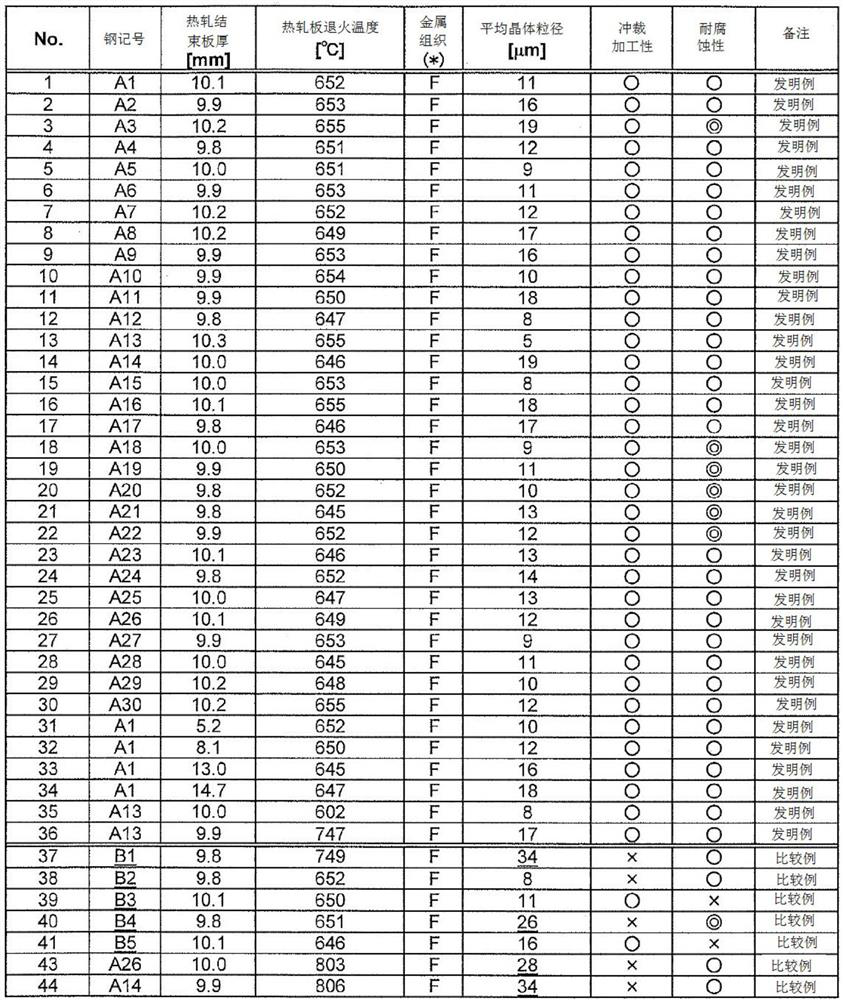

[0088] The molten stainless steel with the chemical composition shown in Table 1 was smelted using a 100 kg vacuum melting furnace. After heating these ingots at 1100°C for 1 hour, they were hot-rolled to the plate thickness described in Table 2 (refer to the plate thickness at the end of hot rolling in Table 2), and then performed coiling simulation treatment in which furnace cooling was performed after holding at 650°C for 1 hour. Made into hot rolled steel plate. Next, after maintaining the temperature described in Table 2 (refer to the annealing temperature of the hot-rolled sheet in Table 2) for 8 hours, the hot-rolled sheet was annealed by slow cooling to obtain a hot-rolled annealed steel sheet.

[0089] It should be noted that the thickness of each obtained hot-rolled annealed steel sheet was the same as the thickness of each finished hot-rolled sheet.

[0090] The following eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com